- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylinder heads

Results for

Cylinder heads - Import export

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

This is the machine used to detect invisible cracks in the Cylinder Head.

Request for a quote

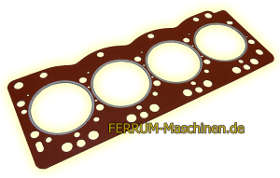

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Spare part for wheel loader FERRUM DM with engine XIN498: cylinder head gasket. Delivery includes the product pictured.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

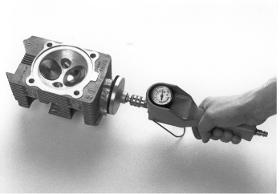

1.Standard Equipment DP1 Valve Leak Detector including a set of seven adapter plates, a flexible extension hose and a sturdy storage case. 2. Working Principle Applying an air pressure of about 6 bar to the DP1 Valve Leak Detector results in a max. vacuum of about 850 mbar which is applied via an adapter plate to the inlet or exhaust port of the cylinder head to check the respective valve for leakage. The vacuum gauge at the DP 1 indicates the tightness of the valve.

Request for a quote

VAGNERSA OTOMOTIV

Turkey

Cylinder head gasket Original and aftermarket

Request for a quote

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

This is a valve angle grinder to functionalize the valves on the cylinder head in the Overhaul Stage.

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

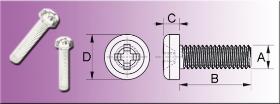

NORELEM FRANCE

France

Workpieces are clamped and released by compressed air. The possible clamping diameter is from 16 to 20 mm. Material: Body, stainless steel. Seal, NBR. Version: Stainless steel bright. Note for ordering: Cylinder head screws M4X35 for fastening from below are included with delivery. Cylinder head screws with low head M5 for fastening from above are not included with delivery. Note: Installed dimensions for plate thickness 6 mm. The stated retaining forces are related to an operating pressure of 0.5 Mpa and a surface quality of Ra 1.6 µm. Repeat accuracy in this case is ±0.2 mm.

Request for a quote

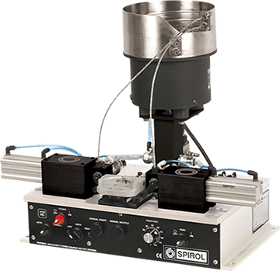

SPIROL

Germany

SPIROL's Model HC Dual Pin Inserter is a lightweight, portable, horizontal Pin Inserter designed to install SPIROL Series 550 Cosmetic Coiled Pins into plastic hinges. The cylinder/driving head modules can be moved in and out with ease, and fixture changes are simple which enables quick conversion from one assembly to another. This machine quickly and effectively delivers the pins automatically to the installation site eliminating the need for the operator to touch them during the entire assembly operation. This machine dramatically increases production efficiency with minimal operator training and effort.

Request for a quote

KASAG SWISS AG

Switzerland

We have many years of experience in grinding and brushing of stainless steel surfaces for all object forms, as well as in the manual and machine grinding of circular objects. Our combined grinding machine/plant can be universally used, owing to its modular construction; it is of premium quality and guarantees surface roughness for stainless steel surfaces, on the inside and the outside for cylinders, spherical heads and cones for grinding welding seams superelevations for grinding longitudinal and circular welding seams roots

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1021 series are designed as differential cylinders for applications with high quality requirements in stationary mechanical engineering. All cylinders work with low friction and are characterized by a stick-slip free run. Hub and piston rod protrusions are variable selectable. The cylinder is connected via a head flange mounting with centering shoulder and a threaded shoulder on the piston rod. There are connections for high pressure flanges to SAE 6.000 P.S.I as well as vent holes for a free installation position. With the exception of the piston rod and SAE flange surfaces, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1001 series are differential cylinders for applications with high quality requirements in stationary mechanical engineering. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder is connected via a head flange mounting with centering shoulder and a threaded shoulder on the piston rod. There are connections with screw-in holes for pipe fittings to BSPP ISO 1179-2 as well as vent holes for a free installation position. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP in accordance with DIN 51524 / 51525-1. If you have questions about areas of application or other options, we are happy to answe

Request for a quote

STOPARTS LTD

Turkey

ENGINE MODEL F2CFE613L A026, F2CFE613C A011, F2CFE613N A010, F2CE9684E E017, F2CFE613C B004, F2CFE613N A011, F2CFE614G B002, F2CFE613C B006, F2CFE613R A021, F2CFE614G B003, F2CFE613C B041, F2CFE613S A020

Request for a quote

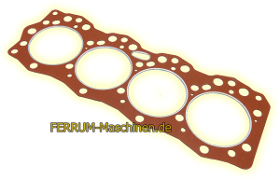

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Cylinder head gasket can be used as a spare part for wheel loader FERRUM DM with engine YTO4105. Scope of delivery corresponds to the illustration.

Request for a quote

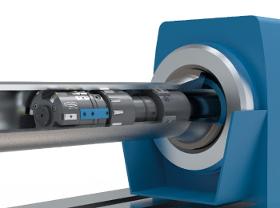

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL's OMEGA system combines skiving and roller burnishing for machining hydraulic cylinders and cylinder liners. While the OMEGA skiving head cuts the cylinder's inner surface to the exact size and form required, the roller head burnishes it. The simultaneous skiving and burnishing process has almost completely replaced honing as the alternative machining process, since it is much more economic and faster. Thanks to its modular design, customized tools can be configured based on pipe quality and machining length. Sometimes for various reasons, tubes have to be skived and burnished separately or both processes have to be carried out one after the other. Therefore, all SK skiving heads can be delivered also as separate tools. SK skiving heads are then used in conjunction with GZ roller burnishing tools. In the first pass the SK skiving head peels the cylinder, and in the second pass the GZ tool burnishes it smooth.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1325 is a multi-purpose equipment for engraving, cutting and 3D milling sheets of materials. WATTSAN A1 1325 has a grid type working table of 1300×2500×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. A spindle ER-25 with collet has power of 3 kW, water cooling system. The portal moved by step engine controlled by driver Yako 2405. Frame of the machine is welded from steel profiles construction; weight of the machine is 800 kg. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, Syntec control system; chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1616 is a cost efficient, easy-to-use and multi-purpose equipment. The machine performs a cutting and engraving, also WATTSAN A1 1616 can perform a 3D milling. WATTSAN A1 1616 has working area of 1600×1600×200 mm, spindle ER-25 with power of 2.2 kW, water cooling system. The portal is moved by step engine controlled by driver Yako 2405. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 500kg. Max speed of spindle movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The working table has a T-slot grid plate. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М1 1313 has a grid type working table of 1300×1300×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. The construction includes a spindle ER-25 with collet and power of 2.2 kW, water cooling system. The portal moved by step engine driver Leadshine 860. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 700kg. Max speed of spindle movement along axis is up to 25 000mm/min, max working speed is 15 000mm/min. Spindle rotation speed can reach 24 000 rpm. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN М1 1616 belongs to М1 series, that is considered more technically sophisticated than A1 series and has a massive frame. The frame is more stable and allows process more complex parts. The machine is applicable for cutting of wood, MDF, chipboard, acryl, plexiglas, PVC, aluminum, composite. Using WATTSAN М1 1616 you can also perform a 3D milling. WATTSAN М1 1616 has a grid type working table of 1600×1600×300 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 18 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Eurobalt Engineering is an Estonian company specializing in manufacturing metal parts by using various technologies. Our products are shipped to the countries of the EU, Asia, and the CIS. One of our major business areas is the production of parts for hydraulic cylinders. Nowadays, competition in the hydraulic cylinder market is a challenge that cannot be underestimated. Decisive factors are price and quality – both of them strongly depend on the efficiency of production and procurement chains of a hydraulic cylinder factory. Our company offers a one stop solution for a hydraulic cylinder factory – we can produce and deliver all kinds of metal parts for hydraulic cylinders so that the factory can focus on assembly and save time and efforts, usually spent on in-house machining. Some examples of the hydraulic parts that we are currently producing: PISTONS END CUPS OF CYLINDERS HYDRAULIC CYLINDER HEAD GLANDS PISTON RODS CYLINDER HOUSING TELESCOPIC PISTONS

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Material: PC Colour: transparent

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The K2000 cylinder head stand is designed to support automotive and motorcycle cylinder heads on a workbench so that service or repair jobs, such as valve work or head cleaning and assembly can be easily performed. Features The cylinder head clamped onto the K2000 can be rotated by 360° and may be fixed at any desired angular position. Therefore, assembly and disassembly work can be done with the cylinder head in the most appropriate position. An universal valve spring compressing lever is supplied to remove and install the valve springs.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application Heavy cylinder heads of large diesel engines can be safely and easily clamped onto the extremely stable WV Cylinder Head Stand to perform maintenance and repair work. If required, the WV can be also used for storing a spare cylinder head. Features The cylinder head mounted on the WV Cylinder Head Stand can be rotated through 360° and locked in any position which is most suitable for the work to be performed. A removeable tray provided in the bottom frame collects any liquid from the cylinder head. Antivibration pads are provided at the bottom frame which are to be secured to the floor so that the stand cannot fall over when mounting and servicing the cylinder head.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The RCM is designed for refacing - the landing surface for the cylinder liner on the engine block, - the landing surface for the cylinder head on the cylinder liner - the landing surface for the cylinder liner on the cylinder head. Capacity Refacing diameter range 200 - 720mm Features The RCM is fitted with two motors providing a smooth cutting action. The speed of the motors is infinitely variable so that the cutting speed can be adapted to the diameter and material of the landing surface. A separate power supply unit is provided for ease of operation. A small hand-held remote control is supplied so that the operator can conveniently switch on and off the machine while watching the refacing operation. The remote control includes an emergency stop to stop the machine in case of emergency. The RCM is centered by a pilot tailored to the specific engine component to be serviced.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD4HD-RC is designed for refacing • the landing surface for the cylinder liner on the engine block, • the landing surface for the cylinder head on the cylinder liner and • the landing surface for the cylinder liner on the cylinder head. Features Drive unit and gear head of the VD4HD-RC are identical with the drive unit and gear head of the VD4HD Valve Seat Refacing Machine. If you have already a VD4E machine and you want to use it with our new face turning heads, we can convert it into the new high performance VD4HD System. The three available face turning heads should be used according to our recommendation with the VD4HD drive unit and the related power supply type 4HD. We would be glad to advise you about our new VD4HD system and send you an offer for this. The D4/0° adapter head is bolted to the gear head in place of the valve seat refacing head. The VD4HD-RC is centered by a pilot assembly which is designed to fit to the engine component to be serviced.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application With the PVM1 assembly set, worn valve guides can be quickly and easily removed from the cylinder head and new valve guides inserted into the cylinder head. The assembly set is particularly suitable for motorcycle, car and commercial vehicle workshops. Features The air hammer can also be used to drive valve seat inserts out of the cylinder head. For this purpose a Hunger valve seat turning device is used to turn a groove into the valve seat ring. The seat ring is driven out of the cylinder head by means of a clamping head whose expandable clamping elements engage in the groove. Handling Insert the appropriate drift pin into the pneumatic hammer and insert the drift pin into the valve guide. Switch on the compressed air supply with the control lever provided on the pistol grip of the air hammer. The valve guide is driven out of or into the cylinder head by the rapid impact sequence. A soft protective ring placed on the drift pin protects the valve guide from damage.

Request for a quoteResults for

Cylinder heads - Import exportNumber of results

45 ProductsCountries

Company type

Category

- Paint mixers and grinding machines (6)

- Milling - machine tools (4)

- Construction - Machines & Equipment (3)

- Cylinders, hydraulic (3)

- Engines & Parts (3)

- Construction machinery (2)

- Spare parts for cars (2)

- Turning - steels and metals (2)

- Washing machines, domestic (2)

- 3D printers (1)

- Agricultural machines and accessories (1)

- Clamp collars, plastic (1)

- Construction - portable power tools (1)

- Cutting - steels and metals (1)

- Die casting moulds (1)

- Disposable medical and surgical articles (1)

- Filtering equipment and supplies (1)

- Grinding - steels and metals (1)

- Leak detectors (1)

- Mechanical engineering - custom work (1)