- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- disc springs

Results for

Disc springs - Import export

SPIROL

Germany

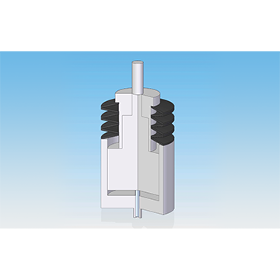

SPIROL offers Disc Springs pre-stacked in custom configurations (greased or ungreased) packaged in shrink wrap with a perforated tab for ease of insertion into the assembly. The Pre-Stacked Disc Springs are delivered intact which saves time, mistake-proofs the assembly process, and eliminates the mess associated with greasing the stack. Have an existing Pre-Stacked Disc Springs Application? If you have an existing Disc Spring Stack that you would like quoted, please Request a Quote. We are here to help!

Request for a quote

SPIROL

Germany

SPIROL offers a line of austenitic stainless steel Disc Springs in diameters ranging from Ø8mm to Ø71mm. Austenitic stainless steel is typically used for static and low cycle applications that require a heightened level of corrosion resistance. It withstands fresh water and atmospheric marine conditions very well, and is suitable for many other industrial conditions including acidic environments. This material will continue to work harden with use so cycle life is limited, but creep resistance is good. SPIROL supplies both single Disc Springs as well as Pre-Stacked Disc Springs in custom configurations, packaged in shrink wrap with a perforated tab for easy of assembly.

Request for a quote

SPIROL

Germany

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process. SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series, they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling. Visit www.SPIROL.com to learn more!

Request for a quote

SPIROL

Germany

The mechanical back-up design uses SPIROL® Disc Springs. Under normal circumstances, the hydraulic system holds a constant pressure on Disc Springs stacked in series. If pressure fails to be maintained, the stack of Disc Springs decompresses to actuate the braking mechanism. A compression spring or wave spring is not capable of providing the force required (in the space available) to actuate the brakes. The reliability of this safety system is dependent on the consistent performance of Disc Springs. In this critical application, the Disc Spring’s performance and level of predictability improves product quality and ensures overall safety. SPIROL® Disc Springs have a high capacity to consistently store releasable mechanical energy. Visit www.SPRIOL.com to learn more!

Request for a quote

SPIROL

Germany

DEWALT’s lead design engineer for drills was tasked with designing a high power right angle drill that is lightweight, compact, and portable. The goal with the design was to maximize performance while minimizing the size of the tool. The design would incorporate a mechanical clutch built to limit maximum torque output to 70 ft-lbs. Absent the clutch, with the huge gear reduction of 75:1, the drill would be capable of producing a lock rotor torque at the spindle of 175 ft-lbs, transmitted directly to the operator of the tool. It was determined early on that the clutching thrust required in the space available could only be achieved by a Disc Spring design. Compared to conventional coil springs, Disc Springs offer a higher load capacity in less space. Additionally, longevity and reliability is a high measure of quality for professional tools used on a daily basis. The life and performance warranty of the tool was reliant on the Disc Spring design. Visit SPIROL.

Request for a quote

SPIROL

Germany

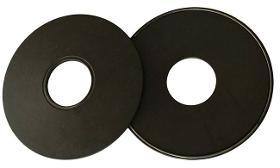

Disc Springs are conically-shaped precision components designed to be axially loaded. Disc Springs are often incorrectly referred to as belleville disc springs, belleville springs, belleville washers or simply conical washers. SPIROL offers the full range of DIN EN 16983 (formerly DIN 2093) Group 1 and 2 Disc Springs in Series A, B, and C. In addition to the DIN specified sizes, SPIROL stocks its own standard sizes with outside diameters ranging from Ø8mm to Ø200mm. SPIROL Standard Disc Springs were designed around the standardized calculations of DIN EN 16984 (formerly DIN 2092), and meet all material, dimensional tolerance, and quality specifications as laid out in DIN EN 16983 (formerly DIN 2093) yet offer an expansion in the diameter and thickness combinations that are not included in the DIN standard. Standard materials include carbon steel and alloy steel, both finished with a protective coating of zinc phosphate and oil.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Disc springs (also called Belleville springs) are geometrically a cylindrical washer with a slightly conical shape. It is used as compression spring and is the best solution when forces are high and travel relatively limited. This type of springs can or in parallel, which increases travel and/or force.

Request for a quote

FÖHRENBACH GMBH

Germany

Automatic clamping takes place over disc springs, which are adjustable in the pre-loading and are solved pneumatically to the workpiece change. Manual clamping is made by a knurled knob on the opposite side of the collet. Due to the integration into the existing through-hole of the rotary table, the rotary table with the clamping system remains very compactly. Compact High run-out accuracy Easy to operate Retrofit possible

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Nova Swiss safety heads provide dependable safety and protection in the event of overpressure. The safety heads can be equipped with different bursting discs for a range of burst pressures. The bursting discs can be replaced easily and cost-effectively. Safety heads are supplied complete with screw fittings.

Request for a quote

HEWEI DISC SPRING MANUFACTURING CO., LIMITED

China

Made of high temperature material as Inconel 718 , 750 , Nimonic 90 , these disc springs can be used under 600℃ in the special Chemical circumstances .

Request for a quote

HEWEI DISC SPRING MANUFACTURING CO., LIMITED

China

Disc springs for bearings are assembled with the ball bearings to act as retention devices. Disc springs act as a compensator of thermal expansions during their working.

Request for a quote

HEWEI DISC SPRING MANUFACTURING CO., LIMITED

China

Made of stainless as SUS301, 302 ,316 , 17-4PH , 17-7PH , 15-7Mo,these disc springs' resistant to corrision is higher than spring steel .

Request for a quote

HEWEI DISC SPRING MANUFACTURING CO., LIMITED

China

Wire-segment Disc springs are self-guided disc springs with the help of wire segments . Wire segments material as spring steel or Stainless steel .

Request for a quote

FAIRON BEARINGS INTERNATIONAL

Belgium

Mubea is an international synonym for spring technology of the highest standard. Our disc springs comply with the highest worldwide quality standards. Our products are manufactured in Daaden, Germany - combining extensive know-how, modern quality control and decades of experience. Mubea has specialised in the production of quality disc springs for more than 40 years. Because of their versatility, disc springs are used in a large variety of industrial applications, ranging from safety valve systems placed 3000 m below sea level to satellites in outer space. Additionally, Mubea also excels in the production of related products, such as complex precision stamped parts. Disc springs in compliance with DIN 2093, as well as our own internal standards, are in stock on a permanent bases. Mubea manufactures disc springs with an outside diameter up to 800 mm, as well as internally and externally slotted disc springs, and wave springs. All products are manufactured in-house, beginning with the p

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Classic Line includes DC spring-pressure single-disc and multi-disc brakes which, due to their robust design and the variable connection technology, meet the requirements of demanding applications. Electromagnetically-operated spring-applied brakes build up the braking torque when the current is switched off and the electromagnetic force is therefore neutralized.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Elevation Line includes both DC spring-pressure single-disc brakes as well as spring-pressure double-disc brakes which comply with EN 81 (Safety Regulations Concerning the Design and Installation of Elevators). Integrated micro-switches allow for remote inquiry of the brake condition (armature position, wear, armature bearing). Owing to the patented safety concept, the otherwise mandatory testing of the dual-circuit braking system of the spring-pressure brake at the approval of the elevator system can be dropped. The brake can be used in places where short construction lengths with respective system components like motor, gear and brake must be realized. The Elevation Line is primarily used for elevators, but can be used wherever the brake must meet demanding safety requirements. Electromagnetic spring-pressure brakes build up the braking torque when the current is switched off.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KENDRION (VILLINGEN) GMBH

Germany

The Slim Line includes spring-pressure single-disc brakes for brake discs mounted non-positive on the shafts to be retarded. The brake disc, which is permanently connected to the shaft, can be designed as a motor fan. Owing to the single-disc brake design, SLIM LINE brakes are particularly flat. Based on the working principle, residue-free lifting is achieved. Electromagnetically-operated spring-pressure brakes build up the braking torque when the current is switched off.

Request for a quote

IGUS® GMBH

Germany

Polysorb Disk springs delivery program De [mm]: Di [mm]: disc springs are annulus discs stressable in the axial direction, which are turned over in the shape of a disc in the axial direction. disc springs provide a more favorable space usage than other spring types. They are particularly suitable for designs that demand a small spring deflection. + When not to use Polysorb Disk springs? For the implementation of specially flat load deflection curves that are possible with metal only with considerable complexity and expenditure (slotted versions). For compensation of axial clearance and manufacturing tolerances For vibration compensation For noise dampening When an antimagnetic material is required For electrical and thermal insulation When no corrosion problems should arise When lubrication is not necessary For low weight For low space requirement – When not to use polyserb disk springs? When constant spring forces are necessary over a wide temperature range When high spring forces are required The spring deflection of the disk spring is relatively small. Therefore a number of disk springs are combined in practice. Alternatively layered disk springs enhance the spring deflection in proportion to the number, whereby the overall spring force is as large as the force of the individual disk spring. To increase the force, the disk springs can be layered in parallel as a spring packet. Chemical resistance Polysorb disk springs are resistant to many chemicals. iglidur® A500 has a higher resistance than iglidur® J. Medium Resistance iglidur® J iglidur® A500 Alcohols + + Hydrocarbons + + Fats, oils without additives + + Fuels + + Diluted acids 0 to - + Strong acids - + Diluted bases + + Strong bases + to 0 + Humidity absorption The low humidity absorption allows them to be used in wet or humid environment. Polysorb® disk springs absorb humidity. Thereby their mechanical properties alter. In the worst application that can be thought of - extremely long application in water - Polysorb® disk springs still exhibit high spring force. iglidur® Standard environment saturated in water J 18 15 A500 24 23 Increased operating temperature Increased temperatures lead to the decline of stiffening in polymers. Polysorb® disk springs exhibit a maximum spring force of 8 N even at the maximum permitted temperature of 80° C. See figure for relationship of spring force to ambient temperature. Polysorb Disk springs long-term tests X = downward deflection [%] Y= spring force [N] A = JTEM-10 B = A500TEM-10 Figure 35.1: Spring force depending on the percentage of deflection measured in installation size 10 X= Ambient temperature [°C] Y= Maximum spring force [N] Figure 35.2: Influence of the ambient temperature on the spring force, measured on JTEM-10 Polysorb Disk springs delivery program De [mm]: Di [mm]: Dimensions according to DIN 2093

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

Punching units Punching unit with exchangeable cutting elements for sheets and profiles up to a material thickness of 25.0 mm and a hole diameter of 150.0 mm JOKA punching units consist of a special cast stand that accepts the punch and die and ensures the exact axis alignment between the cutting elements (punch and die). In addition, there is a stripping system in the upper part of the tool stand, as the material wipes off automatically after punching. The scraper contains two or more disc spring packages that guarantee perfect scraping even in the border areas. A fixed connection between the tool and the upper part of the press is therefore not required. To determine the exact position, each tool has a positioning pin (two for shaped holes) on the underside, which is precisely aligned with the cutting elements (center of the hole). The above picture shows a complete punching unit without cutting elements and one cutting set (punch and die) each for round hole or shaped hole.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

FlexDur FD-C-couplings are flexible compensating couplings of all metallic design which transmit the torque in a torsionally rigid and backlash-free manner. The transmission elements are disc packs of stainless spring steel plates which are attached to the coupling components by closetolerance bolts. The most important characteristics and advantages of FlexDur FD-C couplings: Torsionally rigid torque transmission with zero torsional backlash Wear-free compensation of axial, radial and/or angular shaft displacements ittle restoring forces in the case of shaft displacements Neither maintenance, nor lubrication required For use at ambient temperatures from – 25 °C to + 250 °C Compact design even suited for high and very high rotational speeds Infinite life, proper shaft alignment provided We are glad to see that you are interested in our product line and are happy to answer all questions! Please use our contact form or call us: +49 234 959160. For additional information regarding...

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

With the Therma friction thermocouple you can determine the surface temperature of the brakes while driving. Attaching the mounting adapter puts uniform pressure on the brake disc through the spring-loaded sensor by using a bayonet cap. That perfectly compensates movements caused by centrifugal force and vibrations as well as the volume decrease caused by disc wear while ensuring a valid measurement. The brake disc friction sensor measures the surface temperature of the brake disc. It imparts important insights about the temperature development. That enables an indication about the brake line, intake and temperature radiation. A brake disc that becomes too hot during a race massively loses its effectiveness and deceleration to the accustomed and optimal degree is no longer possible. If the temperature is too high, the brake pads start gassing on top of that.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg has a friend factory working on wire forming production of all kinds of spring manufacturers, pressure spring, tension spring, torsion spring, clamp spring, shrapnel, special-shaped spring, stainless steel spring, metal spring, tower spring.... There are square steel, flat steel, various stainless steel and tin bronze spring and so on. The wire formed parts as belows: Large spring bending Shaped spring Compression spring Linear spring Hardware hook Torsion spring series Tensile spring Buckle retaining ring Clockwork coil roll Custom Springs Production equipment: computer spring forming machine, automatic spring coiling machine of various specifications, advanced double end spring grinding machine and torsion spring machine of various specifications, etc.

Request for a quote

DANTE MACCHINE AGRICOLE

Italy

TANDEM series was projected to exploit harvest residues to the best, so that it can become a natural fertilizer. The combination of its tools succeeds in working the soil intensively, at a minimum depth. The discs are mounted on independent spring supports. It is possible to choose a cage roller, a paker roller, and a full-flex roller. We produce every model both in standard version, with discs diameter 510 mm; and also in PRO version, it is to say with disc diameter 560 mm.

Request for a quote

DANTE MACCHINE AGRICOLE

Italy

TANDEM series was projected to exploit harvest residues to the best, so that it can become a natural fertilizer. The combination of its tools succeeds in working the soil intensively, at a minimum depth. The discs are mounted on independent spring supports. It is possible to choose a cage roller, a paker roller, and a full-flex roller. Trailed version give an important advantage: medium-power tractors and work with quite large machines (just see it in the table below). The spring brings many benefits, namely their flexibility enables a wider movement while working on stony soils, on the other hand it let residues fall better, because it vibrates more that other support systems. We produce every model both in standard version, with discs diameter 510 mm; and in PRO version, it is to say with disc diameter 560 mm.

Request for a quote

DANTE MACCHINE AGRICOLE

Italy

TANDEM series was projected to exploit harvest residues to the best, so that it can become a natural fertilizer. The combination of its tools succeeds in working the soil intensively, at a minimum depth. The discs are mounted on independent spring supports. It is possible to choose a cage roller, a paker roller, and a full-flex roller. Trailed version give an important advantage: medium-power tractors and work with quite large machines (just see it in the table below). The spring brings many benefits, namely their flexibility enables a wider movement while working on stony soils, on the other hand it let residues fall better, because it vibrates more that other support systems.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The VARIO LINE includes DC spring-pressure single-disc brakes, which can be matched to the individual application due to a wide range of variants. Electromagnetically-operated spring-pressure brakes build up the braking torque when the current is switched off. By means of the electromagnetic force or an additionally mounted hand lifting device, the braking effect can be neutralized. Fitting dimensions and the grading of the type series of the VARIO LINE are matched to IEC motors.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The EEX Line includes spring-pressure single-disc brakes provided with explosion protection for explosion-hazardous areas. The spring-pressure brake with firedamp protection is suitable for underground excavations with danger of firedamp. In spring-pressure brakes with explosion protection, those parts which might ignite explosive mixtures are incorporated in a housing. If the mixture inside the housing explodes, the latter prevents a transfer of the explosion to the mixtures surrounding the housing. The brake is equipped with four thermal circuit breakers and one micro-switch. The micro-switch prevents starting against the unlifted brake. The thermal circuit breakers are series-connected with the micro-switch and interrupt the control circuit of the machine as soon as there is an inadmissibly high temperature at the brake. The brake is seawater-resistant. By means of the attached hand lifting feature, the braking effect can be manually neutralized.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied single-disc brakes in the Servo Line series are designed to operate dry. They can be mounted to the A-face or B-face end shield inside the servo motor. The braking action generated by the compression springs is neutralized by applying the electromagnetic principle involving generation of a magnetic field. The brakes engage in unpowered condition and release when DC voltage is applied. The brakes are equipped with a flange and firmly fastened with screws. Thanks to a specially developed and patented manufacturing method, the rated air gap tolerance can be reduced to a few hundredths of a millimetre, providing enhanced power. Moreover, the brakes have a toothed hub/friction disc connection with minimal circumferential backlash. Standard version is suitable for flange mounting and face mounting.

Request for a quoteResults for

Disc springs - Import exportNumber of results

41 ProductsCategory

- Disc springs (11)

- Brakes, servo-brakes and accessories (7)

- Screw cutting - steels and metals (6)

- Fasteners, metal (3)

- Soil preparation machinery and equipment (3)

- Axles, vehicle (2)

- Agricultural machines and accessories (1)

- Clamp collars, plastic (1)

- Custom design springs (1)

- Fire alarms and detection - equipment and systems (1)

- Fire protection equipment (1)

- Import-export - steels and metals (1)

- Inductive sensors (1)

- Punching machine tools (1)

- Springs (1)

- Steel & Metals (1)

- Trailers (1)

- Valves for industrial fittings (1)

- Wire springs (1)