- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- engineering - industrial consultants

Results for

Engineering - industrial consultants - Import export

NC MANUFACTURING AND ENGINEERING

Turkey

We successfully carry out the mechanical processes of the diesel-cogeneration systems all around the globe. In field applications, we work with our highly experienced teams. In mechanical assembly and manufacture works, all kinds of steel construction, duct, piping, equipment and machinery are assembled and manufactured.

Request for a quote

TOMECH SOLUTIONS

Romania

Structural steel design involves the meticulous planning and modeling of steel components for various applications. In this domain, we specialize in creating robust and efficient solutions for platforms, machine supports, walkways, ladders, and stairs. For platforms, we craft sturdy and well-designed structures that provide elevated surfaces for various applications, ensuring stability and safety. Machine supports are designed to bear the loads and vibrations associated with machinery, contributing to the overall stability of industrial processes. Walkways, ladders, and stairs are crucial for safe and convenient access within industrial facilities. We specialize in structural steel detailing services, offering expertise in creating high-quality drawings and plans that adhere to industry standards and regulations. Our services encompass the full spectrum of structural steel detailing, helping clients reduce costs, and achieve successful project outcomes.

Request for a quote

TOMECH SOLUTIONS

Romania

Hoppers and transfer chutes are essential components of material handling systems, facilitating the smooth movement and transition of bulk materials within industrial processes. We specialize in hopper and chute design services, offering tailored solutions to optimize material flow, minimize downtime, and improve overall system performance. Our expertise encompasses the design, analysis, and optimization of hoppers and transfer chutes to meet the specific requirements of our clients and enhance the efficiency of their material handling operations.

Request for a quote

TOMECH SOLUTIONS

Romania

Conveyors are mechanical devices used to transport materials from one place to another within a facility or between different locations. They are integral to numerous industries, including manufacturing, logistics, and transportation. Types of conveyors include: belt conveyors, roller conveyors, screw conveyors, chain conveyors, gravity conveyors, bucket conveyors. We specialize in conveyor design services, tailoring solutions to meet the unique needs of our clients. Our expertise covers the design, optimization, and implementation of conveyor systems to enhance efficiency, productivity, and safety in diverse industrial settings.

Request for a quote

TOMECH SOLUTIONS

Romania

Screens play a crucial role in material handling and sorting processes by separating particles based on size, shape, and composition. They are commonly used in industries such as mining, construction, recycling, and agriculture to classify and sort bulk materials efficiently. Screens consist of a surface with apertures or perforations of varying sizes, through which material passes. As the material moves across the screen surface, particles smaller than the aperture size fall through, while larger particles are retained. Screens can be vibratory or stationary, depending on the application and required throughput. We specialize in screen design services, offering customized solutions to optimize screening efficiency, throughput, and product quality. Our expertise encompasses the design, selection of screen media, and configuration of screening equipment to meet the specific needs of our clients and enhance the performance of their material handling and sorting operations.

Request for a quote

TOMECH SOLUTIONS

Romania

Plant layout design is the strategic arrangement of equipment, machinery, workspaces, and facilities within an industrial plant or manufacturing facility. It involves optimizing the physical layout to maximize efficiency, productivity, safety, and workflow throughout the entire production process. Key considerations in plant layout design include: workflow optimization, space utilization, safety and ergonomics, flexibility and adaptibility, compliance and regulations. We specialize in plant layout design services, offering expertise in developing customized layouts that meet the unique needs and objectives of our clients. Our services encompass the entire design process, from initial conceptualization and space planning to detailed layout drawings and implementation support. By leveraging our experience and knowledge, we help clients optimize their plant layouts to enhance efficiency, productivity, and competitiveness.

Request for a quote

TOMECH SOLUTIONS

Romania

Bulk handling equipment encompasses a diverse range of machinery and systems designed to efficiently transport, store, and handle large quantities of bulk materials such as ores, minerals, grains, chemicals, and aggregates. These equipment play a vital role in industries such as mining, agriculture, construction, and manufacturing, facilitating the movement of materials along various stages of the supply chain. We specialize in the design, engineering, and integration of bulk handling equipment, offering customized solutions to optimize material handling efficiency, minimize downtime, and enhance overall operational performance for our clients across various industries.

Request for a quote

TOMECH SOLUTIONS

Romania

Feeders are devices used to regulate and control the flow of bulk materials from a storage container or hopper to downstream processes or equipment. They play a vital role in ensuring a steady and controlled supply of material, enhancing the efficiency and productivity of material handling systems. Vibrating feeders are a type of feeder that utilizes vibrations to move materials along a trough or tube. Vibrating feeders are commonly used in industries such as mining, aggregate processing, and pharmaceuticals due to their ability to handle a wide range of materials and feed rates while minimizing spillage and dust emissions. We specialize in feeder design services, offering tailored solutions to optimize material flow, feed rate, and system performance. Our expertise encompasses the design, selection of feeder type, and integration of feeding equipment into material handling systems to meet the specific requirements of our clients and enhance their operational efficiency.

Request for a quote

TOMECH SOLUTIONS

Romania

3D laser scanning is an advanced technology employed for capturing highly accurate three-dimensional information of physical objects and environments. As part of our service offerings, we provide comprehensive 3D laser scanning services, which include: 3D laser scanning services, 3D point cloud generation, creation of as-built documentation, clash & interference checking, 2D & 3D modeling, reverse engineering, 3D virtual tours.

Request for a quote

TOMECH SOLUTIONS

Romania

We proudly offer specialized 3D CAD engineering services across diverse domains to meet the unique needs of our clients. In the realm of bulk material handling, we excel in creating precise and customized 3D models for conveyors, stackers, and reclaimers, optimizing material flow and system integration. Our expertise extends to recycling, where we design and model equipment such as conveyors, shredders, crushers, balers, and waste-to-energy plants, ensuring efficient and sustainable processes. Additionally, our capabilities extend to custom 3D works, allowing us to transform creative concepts into reality through digital modeling. Whether it involves unique product designs, artistic installations, or specialized components. Our commitment lies in delivering precise and efficient designs that cater to the specific requirements of each sector, ensuring that our clients receive tailored solutions that meet industry standards and regulatory compliance.

Request for a quote

ALUMINIUM GIETERIJ OLDENZAAL B.V.

Netherlands

AGO is more than just a supplier; our years of experience make us the right partner for you to achieve the optimal result together. To achieve a product that is well cast, AGO offers its customers the opportunity to make use of its engineering department. Using various CAD software, our engineers closely collaborate with the customer, preferably from the design phase, in order to achieve the most effective solution. Starting the cooperation early on in the process prevents changes having to be made afterwards, which means cost and time savings. OUR STRENGTHS AGO = innovative strength Partnership with our customers from idea to final product Total Cost of Ownership approach Substitute analysis and re-engineering OEM ? development partner Reversed engineering Product and composition engineering Casting simulation and component optimisation 3D CAD, including SolidWorks, Catia, Pro-E and VisiCAD Prototyping R&D in close cooperation with various partners

Request for a quote

MOVINGROUP S.R.L.

Italy

The Movingroup service assists consumers at all phases: - Let's speak about what you need: problem analysis, necessary results, scheduling, and pricing. - We build a technical proposal by selecting materials, profiles, and geometry that are most suited to the working conditions of your systems. - To ensure continuity, one of our technicians will develop and oversee your project from start to finish. - You will assess the product before purchasing it, with test cases performed independently or with the assistance of our application engineers. - After purchase, we stay available to you by allocating a technical support line to resolve any questions or concerns.

Request for a quote

ENTRIVE STUDIO

Netherlands

As part of the product development process, we always keep in mind the manufacturer's point of view. Meaning that we design from the start to minimize the problems of production and keep the budget tight. With an in-depth knowledge of manufacturing processes, we optimise the design for lowest production cost and lowest manufacturing risk. Regardless if you're planning to make just a few pieces, a few hundred, or thousands. Some of the processes we're proficient with are: - injection moulding of hard plastics, silicone and rubber - sheet metal forming - assembly - 3D printing (FDM, SLS, SLA, FGF) - packagings - CNC milling - spinning, turning - woodworking - and more Design for manufacture also includes working out and testing every detail of the product, including snap fits, colours and finishes, tolerances and clearances.

Request for a quote

MAXRAY KIMYA SANAYI VE TICARET LIMITED SIRKETI

Turkey

Motor üzerindeki yağ, gres ve inatçı kirlere çok hızlı bir şekilde nufuz ederek, kirleri çözer. Motor aksamında herhangi bir bölüme zarar vermez. Akü, distribütör, alternatör gibi elektrik parçaları kapattıktan sonra uygulama yapılır. Temizliğin yanında, parlak ve yeni bir görüntü sağlar.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

For over 20 years LUBCON provides inspections on failed or damaged ball and roller bearings. Understanding why a bearing has failed is essential to prevent the same failure from happening again. Detailed bearing analysis including inspection report: The report will usually cover more than 5 pages and include images, comments regarding possible failure modes and recommendations for preventive actions if appropriate. Remote analysis with short report: A short report will usually cover 2 to 4 pages and include comments regarding possible failure modes and recommendations for preventive actions if appropriate. Our Application Engineers as well as our Laboratory Staff have extensive experience in bearing technology, tribology and chemistry. If you're interested in a bearing and/or lubricant analysis please call us on +44 (0)1323561030 or send an email to service@lubcon.co.uk

Request for a quote

FORMEON

United Kingdom

3D scanning aids engineering, reverse engineering, and quality inspection, streamlining development in sectors like motorsport, aerospace and manufacturing. Accurately capturing complex shapes and forms with high accuracy and speed, surpassing traditional measurement methods in many ways.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OSTEC ARTTOOL LIMITED COMPANY

Russia

A lightweight and compact vibration absorption systems allow to significantly reduce unwanted vibrations translated to working environment from noisy pumps, compressors, etc. Developed by engineers, physicists and leading industry consultants with expertise in vibration isolation and precision instruments, AVOS ST systems significantly absorb vibrations and disturbances.

Request for a quote

OSTEC ARTTOOL LIMITED COMPANY

Russia

AVOS AR is a lightweight and compact tabletop active vibration isolation system that counteracts unwanted vibrations for sensitive equipment. The streamlined design allows it to seamlessly become part of the workstation environment. AVOS AR's straightforward composition requires no follow-up tuning. Developed by engineers, physicists and leading industry consultants with expertise in precision instruments, AVOS AR's effectiveness at significantly reducing vibrations and disturbances mark it as a revolutionary and critical tool for laboratory use Among others, we offer solutions for standalone systems and integrated OEM systems: - Standalone Of-The-Shelf Products - Integrated OEM Solutions - Customized Solutions It is possible to install a built-in shaker for testing how the target system or device performs under different vibration conditions

Request for a quote

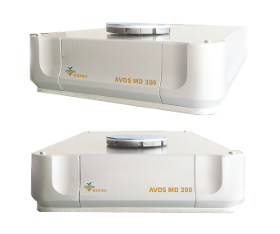

OSTEC ARTTOOL LIMITED COMPANY

Russia

AVOS Integra is a lightweight and compact tabletop active vibration isolation system that counteracts unwanted vibrations for sensitive equipment. The streamlined design allows it to seamlessly become part of the workstation environment. AVOS Integra's straightforward composition requires no follow-up tuning. Developed by engineers, physicists and leading industry consultants with expertise in precision instruments, AVOS Integra's effectiveness at significantly reducing vibrations and disturbances mark it as a revolutionary and critical tool for laboratory use. Two rectangular platforms Single platform dimensions - 800 (length, resizable) x 300 x 75 mm Two active isolators on each platform

Request for a quote

OSTEC ARTTOOL LIMITED COMPANY

Russia

Our lightweight and compact modular active vibration isolation systems counteract vibrations affecting sensitive equipment. The streamlined design allows easy installation procedure and its straightforward composition requires no followup tuning. Developed by engineers, physicists and leading industry consultants with expertise in precision instruments, AVOS MD 300 effectiveness at significantly reducing vibrations and disturbances mark it as a revolutionary and critical tool. Stationed on multiple, independent isolators up to 8 isolators AVOS MD 300 has the capacity to support load capacities of massive machines and heavy tool systems.

Request for a quote

LEAN REŠITVE

Slovenia

Lean manufacturing comes from the automotive industry. Lean Solutions we offer a wide range of advice in the field of process optimization in production, logistics and administration and help our clients build an organization for lean manufacturing. With the help of Lean methods and elimination of losses in processes, we present and show our clients in practice what it means. Consulting with an emphasis on 80% of consulting time in production and 20% of consulting time for customer training needs. Joint preparation of time plans and reporting is a constant practice in our work. Consulting is the optimal combination for achieving the customer’s goals and introducing a lean culture. Lean manufacturing originates from automotive industry, but lean manufacturing methods are suitable for virtually all activities. When we talk about “coils” of production and logistics, we are talking about production and logistics that operate without unnecessary losses and have optimally organized all busi

Request for a quoteResults for

Engineering - industrial consultants - Import exportNumber of results

23 ProductsCountries

Company type