- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flat grinding

Results for

Flat grinding - Import export

WMC SINTERSTAR AG

Switzerland

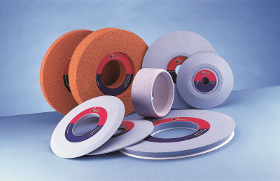

We represent the Sebald company in Switzerland. This company manufactures ceramic grinding wheels in its own production in Germany and has an excellent track record. With this we want to offer our customers an improved service. We look forward to conducting appropriate trials with you.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Rigid machine for heavy duty belt grinding. The machine can be adjusted for horizontal or vertical position. Various options include: Dust extraction, chamfering device, angle guide roller, longitudinal stop.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Tool making & construction: The key to success We know the different industry-specific requirements for stamped parts and parts suppliers. Therefore, our day-to-day work includes very demanding tasks, which we overcome speedily and process reliably. Our spectrum of services for tool construction includes: 3D-CAD/CAM construction and programming (solid works, Peps, HSMworks) Wire-cut EDM (also contract manufacture) with workpiece sizes up to max. 600x400x350 mm Drilling erosion (start hole shooting) with workpiece sizes up to max. 250x350x300 mm Milling technology with workpiece sizes up to max. 650x500x500 mm Turning technology with workpiece sizes up to max. dm 210 x 1000 mm Flat grinding with workpiece sizes up to max. 600x300x375 mm and more…. Even complicated customer requirements are never a problem for us, but are instead a welcome challenge.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

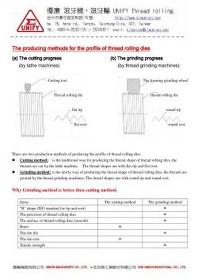

Specification: There are 2 producion methods of producing the proflie of thread rolling dies: Cutting method: is the traditional way for producing the thread shape of thread rolling dies, the threads are cut by the lathe machine. The thread shapes are with flat tip and flat root. Grinding method: is the newly way of producing the thread shape of thread rolling dies, the threads are ground by the thread grinding machines, teh trhead shapes are with round tip and round root. Why we choose the grinding method for UNIFY thread rolling dies, please check the above for the reason. Currently, we have more then 10 units of REISHAUER thread grinding machines (Swiss made) in our factory. The thread rolling dies offered by UNIFY are always the grinding type. The higher level quality can be ensured!

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

Our vertical grinding centre RP 8 is the optimal machine for the complete machining of highly complex workpieces in one clamping. The RP design impresses with the following unique features: —5-sided complete machining —Highest machining and measuring accuracies —Stable cast iron construction —Hydrostatic bearings in the X, Y and C axes —Wear-free direct drives in the X, Y and C axes —Outstanding long-term accuracy and durability —Table diameter 800 mm —Max. 2,000 kg continuous table load —Excellent damping properties —Up to 2 grinding spindles on grinding head —Different tool changing systems available —All machining operations of the Ri grinding centres —Turning and milling operations —Horizontal machining —Guide path grinding —3-axis coordinate machining —Flat grinding in pendulum motion —Machining of special materials such as special types of glass or ceramics — Surface grinding in pendulum motion

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

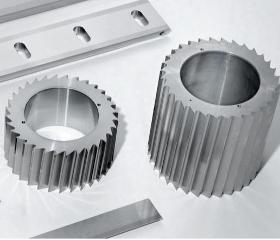

The BG handles the grinding of flat and round broaches with ease. It finds its place mainly in the automotive and aerospace industries. Design and programming of the BG is based on many years of design and manufacturing experience in the tool industry. The BG signifies not only a machine concept but also a complete technology package consisting of machine and competence in tool manufacturing. The BG 1000 / 2000-T models are very compact traveling table machines for the grinding of broaches up to 200 mm diameter. They are designed to grind straight and helical teeth with very stable grinding behavior. The BG 2000 / 3000-C models are based on the moving column principle and display very consistent machining even on very heavy workpieces. They are designed for broaches up to 600 mm diameter. The distinguishing characteristics are profile precision, maintaining center and ease of use. Grinding of inner features is available as an option.

Request for a quotePOUGET

France

USE : To descale new rails before stepping-up.(scale acts an insulator). ADVANTAGES : Simple and efficient machines to remove scale (carbon deposits) Portable Machine equipped with : - 1 Sensitive Lowering Adjustment Device - 1 Folding Wheel It can be use as : RAIL HEAD SCRUBBER MACHINE Equipped with : - Metal Descaling Brush Ø 120 mm made in hardened Steel Wires - 4-stroke petrol engine 4 KW - Ref. NB-1D - Triphase 220/380 V Electric Motor - Ref. NB-1DE - Weight 54 Kg Equipped with : - Lamella Brush Ø 250 mm Rod - 4-stroke petrol engine HONDA 4 KW - Ref. NB-2D - Triphase 220/380 V Electric Motor - Ref. NB-2DE - Weight 47 Kg RAIL GRINDING MACHINE Equipped with : - Flat Grinding Wheel Ø 150 mm (other Ø on request) - 4-stroke petrol engine HONDA 4 KW - Ref. NB-1M - Triphase 220/380 V Electric Motor - Ref. NB1-ME - Weight 54 Kg

Request for a quotePOUGET

France

BM.100 Rail Grinder - HONDA 4-stroke petrol engine, 2.1 KW - Flexi-Horse, length 1.50 m. - Ø 90 and 72 mm Grinding Wheels ( Face Wheels) - Ø 80 and 125 mm Grinding Wheels ( Flat) - Weight = 23 Kg MP.10 Rail Grinder - ROBIN 2-stroke 2.4 KW - 78,5 cm³ - Flexi-Horse 1.50 m - Ø 50 and 72 mm Grinding Wheels ( Face Wheels) - Weight = 10 Kg - Grinding of Fishplate Joints with Disks (Ref. 1039-M.5 / 1039-H / 1039-P) OPTIONS : Electric Motor 1300 W (Ref. MPE.10) MP-120 Rail Grinder - HONDA 4-stroke petrol engine - 4.4 KW - Flexi-Horse, length 3.50 m - Face Wheel Ø 150 mm - Weight = 59 Kg MP-121 Rail Grinder Manual Grinding of Rail Welds allowing to ensure a perfect finish grinding and dressing. - HONDA 4-stroke petrol engine 8 CV - 6 KW - Steel Frame with inflatable Wheel - Insulating Sheathed Flexible Transmission length 4.5 m - Quick coupling for Ginding Wheel Handling - Ø 125 or 150 mm Grinding Wheels (Face Wheels) - Ø 150 or 200 mm Grinding Wheels (Flat) - Driving control for starting or

Request for a quotePOUGET

France

BM.100 Rail Grinder - HONDA 4-stroke petrol engine, 2.1 KW - Flexi-Horse, length 1.50 m. - Ø 90 and 72 mm Grinding Wheels ( Face Wheels) - Ø 80 and 125 mm Grinding Wheels ( Flat) - Weight = 23 Kg MP.10 Rail Grinder - ROBIN 2-stroke 2.4 KW - 78,5 cm³ - Flexi-Horse 1.50 m - Ø 50 and 72 mm Grinding Wheels ( Face Wheels) - Weight = 10 Kg - Grinding of Fishplate Joints with Disks (Ref. 1039-M.5 / 1039-H / 1039-P) OPTIONS : Electric Motor 1300 W (Ref. MPE.10) MP-120 Rail Grinder - HONDA 4-stroke petrol engine - 4.4 KW - Flexi-Horse, length 3.50 m - Face Wheel Ø 150 mm - Weight = 59 Kg MP-121 Rail Grinder Manual Grinding of Rail Welds allowing to ensure a perfect finish grinding and dressing. - HONDA 4-stroke petrol engine 8 CV - 6 KW - Steel Frame with inflatable Wheel - Insulating Sheathed Flexible Transmission length 4.5 m - Quick coupling for Ginding Wheel Handling - Ø 125 or 150 mm Grinding Wheels (Face Wheels) - Ø 150 or 200 mm Grinding Wheels (Flat) - Driving control for starting or

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time. • Knives • Slicer Blades • Meat Saws • Mincer Blades

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time. • Granulator Knives • Shredding Knives • Baler Blades • Pelletiser Knives • Compound Knives

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time. • Rotary Slitters • Crush Cut Knives • Multi-Knife Blocks • Knife Holders

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time. • Steel and TCT Paper Knives • 3- and 6-Knife Trimmer Sets • Paper Drills • Bookbinding Knives • Perforator Knives • Knife Management Programs • Packaging Knives and Cutters

Request for a quote

KENNEDY GRINDING LTD

United Kingdom

Kennedy Grinding provides a high quality regrinding service for all types of straight and rotary machine knives. We ensure all knives are straightened and checked for flatness during the grinding process. All customer’s knives are recorded, detailing geometry and wear rate, enabling us to give advance warning when knives are approaching the end of their useful life. We also offer a comprehensive collection and delivery service throughout England, Scotland and Wales. In addition, our technical department is on hand to assist with any problems that may occur. When you are looking for consistency and quality, our reputation and technical expertise assures you of superior regrinds every time.• Rotary Shear Knives • Shear Blades • Rubber Stripper Rings • Shimless Tool Systems • Press Brake Tooling • 5 Axis Grinding

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium oxide cloth, X Flex weight. Main features and benefits: Excellent combination of user friendliness and durability. The cloth used ensures a perfect balance of flexibility and strength. The abrasive tool is efficiently driven by means of a unique 4-split-pin system. Recommended applications: Finishing large flat, concave or convex surfaces; grinding the inner and outer surfaces of tanks and containers. Removing and cleaning weld beads. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic, plastic reinforced by fibre glass, marble, stone.

Request for a quote

BIBIELLE S.P.A.

Italy

Aluminium Oxide flaps and X-Flex weight backing. The central wooden hub has a hole allowing it to be fitted on threaded conical shafts. Main features and benefits: Threaded shafts allow you to fit and remove very quickly while reducing balance control. Recommended applications: Finishing wide flat, concave and convex surfaces; grinding the internal and outer surfaces of tanks, containers and pipes; finishing parts of irregular shape. Work surfaces: Stainless steel, standard steel, alloyed steel, nonferrous materials and alloys.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Flat grinding - Import exportNumber of results

17 ProductsCountries

Company type