- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- food canning and preserving - machinery and equipment

Results for

Food canning and preserving - machinery and equipment - Import export

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Vibration Impurity Separator is mainly used for sunflower seed & kernel, pumpkin seed & kernel and other finished materials processing in end of production line, which can remove broken materials generated in the upstream processing efficiently, and process final product kernel with higher complete kernel rate with higher product value. The equipment is composed of two layers of screen, with fish scale screen and double vibration motor to achieve the best separation effect. At the same time, the machine is equipped with a cyclone dust removal for impurities cleaning effect in some extent. The product has simple structure and excellent sorting effect, and it is an important part of seed and kernel product processing line.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

When color sorter is working, feed hopper in the materials under the actionof vibrator is uniform distribution in each chute. The CCD signal while the materials are dropping is in testing. If it is found that there are unqualified materials or impurities in the materials, the ejector will blow the defective goods in the hopper. Featuring standard mechanical structure and sorting performance, the new optical sorter offers precise and standard sorting for different materials. Different preset product modes can be saved. High-resolutioncustom-made 4096-pixel sensor, customized high-precision ejectors, easy to operate with the user-friendly graphical Interface Advanced long-life LED illumination featuring an alert capability-maximising uptime and ensuring faster service responses. Product characteristics: 1. Adopt global high-end visual identification technology. 2. Shadowless cold light source adjustment automatically. 3. Global leading electromagnetic levitation solenoid valve.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

175 Model Grain De-stoner is suit for stoner removal of sunflower seed ,rice, coffee ,roaster cocoa bean. It have greatly higher capacity basic on the model of 125 Grain De-stoner.The destoner machine is not only improved about transmission and screen, but also equipped exact differential-pressure gauge, which can control air volume and pressure in the screen body effectively to excellent selecting effect.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Positive Type of Gravity Separator is a new gravity machine of positive pressure independently developed by our company. The structure of the equipment is optimized and the capacity have greatly improved basis on previous machine. Blowing gravity table produce specific gravity segregation phenomenon according to air movement and vibration, through adjusting wind pressure, amplitude and other technical parameters, larger proportion materials sink down and smaller proportion drift upward, then different proportion finished products discharge from corresponding outlets. gravity separator can effectively remove mildew grain, Shrivelled seeds, empty seed, moth eaten grain, immature grain and other impurities, widely used in wheat, corn, watermelon seed, sunflower seed, pumpkin seed, all kinds of beans and various oil crops selection processing.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Grain Impurity Screen is used for cleaning different size of the impurities in the materials, such as seeds, wheat, nuts, corn, etc. Raw materials after fed into machine by elevator, light impurities and dust were sucked out through double direction of gravity catcher; The left materials enter into vibratory sieving trunk, there are two layers of sieves and the first layer can separate coarse impurities (large pieces of wood, strings and straw) bigger than the grain, while the second layer can separate fine impurities (sand and broken grain) smaller than the grain. The sieves has vibration mechanism to ensure better cleaning process by adjustable angle of engine, and rubber balls inside for the self-cleaning. This product is widely used in agricultural product processing industry of various materials, and it has become the preferred choice for a grain cleaning machine. It can be applied to the assembly line to achieve the automatic work with cyclone dust separator or pulse

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Grain Grade Cleaner is mainly used to sizing the different sizes of seeds, kernels, nuts, beans, etc. Automatic cleaning & grading procedure adopts dual vibrating motors, rubber shock absorber, different sizes of sieves and rubble balls. Materials are vibrated along sieving deck which has multi-layers, then are graded to different levels by size, while oversized and under sized impurities get removed. Customized various screen mesh and amount of sieve layers that make the vibrating grader has wide range of applications and high grading efficiency. Carbon steel or stainless steel can be chosen for quality standard of the screen materials. The product is installed behind the colour sorting machine for a final quality control, or in front of the seeds shelling machine for pre-cleaning. An optimal design, efficient grading operation and compact structure makes it an ideal grading equipment.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

TFBGZ-400 is the pumpkin seeds shelling machine with seed shelling, sorting and shells removing. The processing materials have high commodity are ensured by systematic shelling procedures, screw transportation, efficient de-huller and vibration separating sieve assembly. The production begins with raw materials being fed in the dehuller and then shelled materials, the kernels separate from covers through vibration sieve, and remove broken kernels. Then the shells are removed using cyclone, seeds and kernel fall into second layer of sieve and continue to be screening, kernels come to finished kernel outlet, at same time, secondary shelling for unshelled seeds from procedures. The equipment can be used with the assembly line, increasing production capacity and reducing production costs effectively.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

Chili stem cutting machine is mainly used for removing fresh or dry chili stalks. It can deliver International leading level top processing performance rate of 600kg per hour. It is crucial equipment for the chili processing market, which can replace a large amount of labor, save operating costs, and improve work efficiency. Frequency converter improves automation and makes regulation easy. Also included in the system are de-impurity, conveyor. The materials are input into a barrel during the rolling process of the sieve cylinder, and stems are cut through outboard blade when the stems stick out from holes with two times, then the chili without stems transferred to next selecting steps.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Pulse-jet bag filter dust collector is environmental protective product in our company. The dust collector designed to collect and store dust and particulate from production and operation, it is widely used to clean air, recover valuable pollutants and remove dust in many different industries including grain processing, woodworking, mine excavating. As dust accumulates on the filter bags, periodic cleaning of the bags in order to maintain continuous operation. This periodic cleaning of bags is achieved by introducing a timed, momentary pulse of compressed air through a blow pipe, with nozzles mounted above each filter bag; An equal amount of compressed air is blown vertically downwards into each bag, the high pressure compressed air creates a shock wave down each bag causing it to release the majority of dust formed around the outside, the removed dust is then

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

SFSP Series Hammer Mill is mainly used for crushing granular materials such as corn, cereals, chaff, sunflower skin, etc.The machine has the characteristics of high output, stable work, safety and reliability, convenient loading and unloading, and easy operation. And it has strong adaptability to materials, and is currently the ideal high-efficiency crushing equipment, which is widely used in processing industries such as grain, feed, oil, food and chemical industry. The grinder applies direct-connect drive. The raw materials in the grinding room are broken into peaces by hammerhead striking and cutting. In addition, the attrition-of among materials and between material and sieve plate makes materials smashed more. Finely ground particles will pass through the sieve but the residues further are ground until them change enough to pass the sieve mesh. So, all the materials will be ground completely.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The device is an automatic quantifying, weighing and packaging device. The material is put into weighing box of machine from inlet, when the weight reaches preset amount, the inlet is closed. After the control system receives the signal that bag is prepared, the material is discharged from outlet into the bag. When all the material enters the bag, the control system opens pneumatic valve, transports the bag by the conveyor and brings it to the sewing machine for sewing. This machine can pack 450-500 bags of materials per hour, and it reduce the labor cost effectively and packing accuracy control. PRODUCT FEATURES ·High efficiency. It adopts three-speed feeding mode with fast, medium and fast speed; ·High accuracy with high-precision control instrument, auto-error correction, auto-overfault alarm, and parameter settings backup in power failure; ·Wide range of weighing, customized bag-sewing machine with auto package sewing and auto-shearing, innovative optical fiber sensing technology.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The screw conveyor is system designed to transportation of loose bulk product from one place to another,alternatively used for waste treatment(shells,peels)loading and unloading the transportation vehicles or silos. The product moves up forward by means of spiral wings in the pipe; When the product reaches to the exit point, products discharged down from the spiral eject point.Using multiple discharge points,screw conveyors efficiently distribute bulk materials to different areas.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The belt conveyor is the more economical method of transporting bulk materials over short and long distances. This is ideal for conveying bulk materials of large lump size, such as crops,fruit, wood,sand,etc.It has a wide belt that slides over a metal bed for smooth,quiet conveying of items placed on the belt from point A to B.The layout of your plant can be simplified and made more efficient with the use of belt conveyors.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

One of the most efficient ways to elevate bulk materials vertically is a bucket elevator. This bucket elevator is suited for transportation of cereals, seeds, fertilizers of granular products. A bucket elevator consists of a series of buckets attached to a belt with sprockets located at the top and bottom of the unit. Bulk materials are loaded into each bucket as the bucket moves past an inlet point. As the bucket goes over the head sprocket, materials pour out of the bucket into a discharge. It is worth noting that our bucket elevator is greatly flexible as it meets the construction requirements of individual plant layouts, i.e. height, bucket width, and carbon or stainless steel build. With weather-proof & dust-proof construction and security measures that are carefully fitted to maintain product integrity and work environment. Thus, that is the reliable bucket elevator of maximum grain throughput and less grain damage base on stable operation in processing production.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width and height, then according to the entrance or exit of workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing? And what is the degree of quality that you need? Where is the proper place for storage finished products? Where is the good exit for finished products transportation by truck? When all these information are gathered then we will be contributing to processing equipment.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

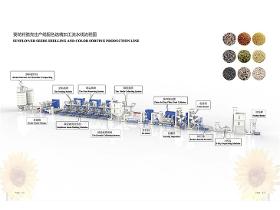

The Sunflower Seeds Shelling Production Line is a convenient processing line with high efficiency and less labor designed by our company for customers with large capacity requirements. It is a combined production line led by KTF5-3000 sunflower seeds shelling machine. The line is designed to confectionery sunflower seeds and remove the husk from the sunflower seeds before pressing the oil. The line processes oil sunflower, from which oil is then pressed. Description of the Line for Sunflower Dehulling (oil pressing): Intake and Cleaning: Sunflower is cleaned from larger and smaller impurities on Grain Impurity Screen Cleaner with an aspiration pre-cleaner. After cleaning, the sunflower is sorted. The Grain Grade Cleaner machine gains a dimensional spectrum of seeds suitable for dehulling. This is followed by destoning on a 125 MODEL DE-STONER.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

With view of the increasing market demand for sunflower kernel oil, basing on 20-year patented dehulling equipments’ manufacturing advantage,the large capacity sunflower seed dehulling equipment for oil pressing purpose KTF5-3000 is our self-developed equipment to meet the needs of large capacity with premium quality of sunflower kernel oil production. Fully Equipped Seed Processing Production Line Plant . It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width and height, then according to the entrance or exit of workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing? And what is the degree of quality that you need

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAPLI SOLUTIONS

Spain

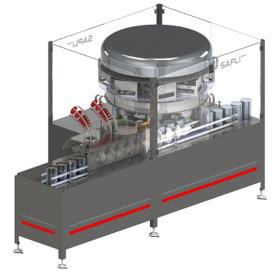

• Vacuumgassing seamers from Sapli are high performance solution for low and high production speeds. • The modular principle allows adding new seaming stations in the future, in case of increasing of production capacities. • Suitable for the seaming and vacuum gassing products in tinplate, aluminium, paperboard and plastic cans packaging across a wide range of industrial sectors. • Perfect sealing technology with adjustable working speeds. • Easy and intuitive format change. • Adjustable levels of residual O2 level after seaming, depending on the product requirements for guaranteeing a long shelf-life of the product. • Vacuum and gassing pressures are configurable, and can be monitored on each can seaming cycle • Guarantying the highest food security and produced with EU Declaration of Conformity. • Suitable for the wide range of tin cans formats, heights and diameters. • Multiformat principle allows working with lots of packaging formats at the same machine.

Request for a quoteResults for

Food canning and preserving - machinery and equipment - Import exportNumber of results

19 ProductsCountries

Company type