- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas furnaces

Results for

Gas furnaces - Import export

KNIGHT OPTICAL (UK) LTD

United Kingdom

Sapphire (Al2O3) is one of the hardest minerals and optical materials available for use in the range from UV up to 5µm. Sapphire is birefringent and if its use is for critical optical application then the crystal might have to be cut along the zero degree plane, or C-Cut. Random cut is usually cut along a plane that is 60° off-axis as the growth in this direction is the easiest to grow. Random cut is anything that is not the C-Cut angle. Sapphire can fluoresce depending upon the concentration of other minerals within the lattice, for example Iron (Fe) or Chromium (Cr). Clear Sapphire might fluoresce orange when illuminated by UV light if impurities are in the crystal. Fluorescent free Sapphire has to be grown from 'pure' feedstock and seed and in an environment that cannot place impurities into the lattice. Click PDF link to read more …...

Request for a quote

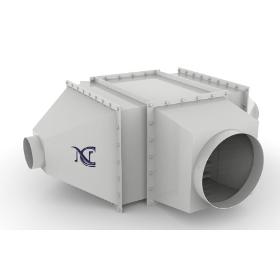

NC MANUFACTURING AND ENGINEERING

Turkey

Recuperator systems are heat exchangers that produce hot air by utilizing the energy of high-temperature waste flue gas generated in furnace systems, boiler systems and various processes. Recuperators various heating needs of facilities such as combustion air preheating and ambient heating are met and energy consumption is minimized. Compared to economizers, they have larger surface area and dimensions at the same heat capacity. They can be manufactured as finned tube and straight tube. Recuperator heat exchangers can be made from numerous materials steel, stainless steel and other special materials.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Extreme-temperature grease on the basis of perfluorinated polyether oils (PFPE) for use in food processing technology at maximum loads and temperatures. Grease lubrication of friction and rolling bearings in the high-temperature range Application, for example at tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals/fuel Advantages and benefits Maximum water and steam resistance Extraordinary resistance to chemicals, for example to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, such as sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Excellent plastic and elastomer compatibility For long-term lubrication of lubrication points subjected to high pressure up to 300°C

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of friction and rolling bearings in the high-temperature range up to 300°C Lubrication of tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals Lubrication of bearings under influence of fuel Advantages and benefits Absolutely resistant to water and steam Resistant to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, for example sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Broad range of applications above the temperature limits of other lubricating greases Excellent wear protection Reduced maintenance and lubricant costs due to possible lifetime lubrication Excellent plastic and elastomer compatibility

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: Hochtemperaturbeständig High-temperature-resistant and strong silicone adhesive and sealant. Especially suited for heat-loaded, elastic adhesive bonding and sealing. Very good adhesion on steel, aluminium, glass, ceramic and many other materials. Applications: Industrial furnaces, Flue gas boxes, Heating facilities, Exhaust pipes and Heating cabinets and furnaces. The outstanding product properties (e.g. permanent elasticity) are maintained in the entire temperature range from -60°C to +300°C. Properties: High temperature resistance up to +300°C, Very good UV stability, Excellent resistance to weathering and aging, Good chemical resistance, Elongation to break approx. 500% and Colour: red.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BTF

Belgium

Electric or gas-fired furnaces, with dimensions and specificities according to your needs Top quality insulation using fibre materials and lightweight insulation bricks Precisely determined power rating Sturdy, precision construction Door fitted on adjustable hinges and fitted with seal Simple and rapid closing system (locking options) Wound resistances, mounted on porcelain tubes to ensure homogeneous radiation Flue installed in the vault & inspection hatch in the door Temperature control system (programmable controller adapted according to the size of the oven and your cooking)

Request for a quote

PLANSEE SE

Austria

Metallic hot zones are made for very high temperatures between 1000 °C (1 832°F) and 2 800 °C (5 072 °F). As a specialist in refractory metals Plansee delivers molybdenum and tungsten hot zones with an excellent form stability and lifetime. Plansee designs and produces hot zones for various types of furnaces (vacuum, protective gas atmosphere, HIP etc) and thermal processes such as sintering, brazing or annealing. Hot zones consist of countless individual parts such as heating elements, shield packs and hearth assemblies and charge carriers. You can find all of these components at Plansee. - Hot zones made from molybdenum, tungsten, tantalum, niobium and their alloys - Full metal or hybrid hot zones with graphite or ceramic fiber insulation - From very small (a few cm³) through to very large (several m³) hot zones - For temperatures of between 1000°C (1832°F) and 2800°C (5072°F) - Tailor-made design: round, rectangular, vertical, horizontal or special geometries

Request for a quote

MAINTENANCE PARTNERS

Belgium

Overhauls & Repairs of Turbo Expanders Maintenance Partners has a broad experience in overhauling and repairing turbo expanders: Single stage radial and axial turbo expanders Multi stage axial turbo expanders Single stage axial turbo expander wheels directly connected to axial compressor – can be in combination with an abradable sealing upgrade to the compressor for increasing efficiency These turbo expanders are utilised in the following applications: Chemical and petrochemical industries Fluid Catalytic Cracking (FCC) Residue Fluid Catalytic Cracking (RFCC) Nitric Acid Acetic Acid Terephtalic acid, or PTA Natural gas and oil industry Pipeline pressure reduction LNG, LPG Liquefaction of methane Coal gasification and hydration General industrial power recovery for example blast furnace top gas expansion Turbo Expander Activities Our services on turbo expanders include: Standard minor inspections Full comprehensive overhauls Re-blading Complete new rotor...

Request for a quote

VATROSTALAC D.O.O.

Croatia

Kerater is used for patching the grill zone of dome furnaces, filling joints between bricks in electric kilns, and for patching industrial kilns. It can still be used for patching gas furnaces or liquid fuels and for coating foundry models for micro casting.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Flowmeters especially for gases The VA 45 variable area flowmeters were designed to measure gases. They can be used, for example, in industrial ovens, forges and furnaces, and protective gas and heating systems. The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The advanced EndoFlex™ endothermic gas generator combines the patented EndoInjector™ fuel injection generator control system with the high-efficiency ReactionCore™ technology to lower operation and maintenance costs associated with producing high quality endothermic gas for your heat treatment furnaces. The generator is equipped with the latest sensors to monitor dew point, unreacted methane, and energy consumption. The touchscreen interface provides easy access to review generator operations, and the integrated paperless chart recorder tracks generator performance to meet production auditing requirements. ReactionCore™ technology is a proprietary generator design that replaces a single large retort with several smaller centrifugally-cast retorts to significantly increase the surface area, improve the heating efficiency of the reaction chamber, and reduce the heating energy required for the production of endothermic gas. In addition, the smaller retort design significantly...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The SmartMeth™ control system is a fully automated nitrogen methanol mixing system for heat treating furnace atmosphere production. The SmartMeth™ utilizes the latest in precision differential pressure flow measurement and touch screen controller design. This first of its kind system with built-in flow rate calculation automatically sets the nitrogen and methanol flow rates based on a desired %CO furnace concentration. FEATURES & BENEFITS • Automatic flow set point calculation - calculates the required nitrogen and methanol flow rates to maintain a desired %CO at the required volume • Customizable recipe software • Optional integrated carbon and temperature control • Automatic atmosphere recovery provides additional synthetic gas flow on demand, when introducing a new load into the furnace • Integrated paperless chart recorder stores furnace temperature, %carbon, and synthetic gas flow furnace details • Completely assembled and tested to NFPA 86 safety guidelines

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The EndoInjector™ is a precise gas mixing / control system for endothermic gas generators. It incorporates a patented fuel injection design that utilizes electronic flow measurement and precise ratio control to consistently provide the ideal gas mixture for high quality endo gas generation. The fuel injection design automatically delivers gas mixture on demand, providing only as much endothermic gas as furnaces require to reduce operating costs and eliminate gas waste. EndoInjector™ typically pays for itself in less than 1 year. The ExoInjector™ is designed specifically for exothermic gas generators. While similar in concept, the ExoInjector™ differs from the EndoInjector™ in that it comes in modified mechanical versions to accommodate pre-mix or nozzle-mix burners with a custom HMI software that allows for predefined ratio set points for burner ignition, rich exo, and lean exothermic gas. The system can be modified to provide hydrogen content control and water vapor monitoring.

Request for a quote

JING DUANN MACHINERY INDUSTRIAL CO., LTD

Taiwan R.O.C.

Application: Quick heating up, low consumption of gas, economic and practical to use. Japan made heat-resistant conveyor chain 4mm, 5mm Maximum diameter, heat and wearing resistant 4mm:8 hours per day, 1 year guaranteed service (most conservative estimate) 5mm:8 hours per day, 2 years guaranteed service (most conservative estimate)

Request for a quote

SAMI KAMMAZ OVENS

Turkey

The Rotary Oven is the ideal and most suitable choice for baking various western bread products, desserts, pastries, and hamburger bread. This oven is widely popular among small and medium bakeries and is best suited for baking a variety of varieties. It has an elaborate air and heat distribution system for baking dough. This oven bakes on gas / diesel as required. Equipped with a cart rotation system, it is suitable for baking bread in a professional way to ensure even heat distribution on the bread. • It bakes all kinds of pastries, Arabic sweets, cakes and all kinds of pastries. • The combustion chamber is made of high chromium material. • The door is designed in a way to ensure that heat does not leak outside, which saves energy • The fuel used in the furnace, diesel or gas, as required. • The oven is equipped with an electrical panel, through which the required temperature, baking time, and required steam time can be controlled with the hood running automatically.

Request for a quoteResults for

Gas furnaces - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Heat treatment furnaces (2)

- Silicones (2)

- Bakery - machinery and equipment (1)

- Bakery ovens (1)

- Chemicals - Basic Products & Derivatives (1)

- Heat exchangers (1)

- Industrial furnaces (1)

- Measurement and regulation equipment and instruments - output and flow (1)

- Mortars and cements, refractory (1)

- Optical instruments (1)

- Ovens, kilns, furnaces and hearths, industrial (1)