- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- finishing work

Results for

Finishing work - Import export

EWM AG

Germany

— Degaussing of pipes and metal sheets — Automatic degaussing before welding — Dependable degaussing for better welding results through stable welding process without magnetic deflection, minimisation of finishing work — activgauss (10–250 A) – degaussing during welding: — Avoids moving up of magnetic field during the welding process in case of very long and strongly magnetised components — Portable and robust — Quick connection at the pipe by means of three load cables — Use at -25 °C to +40 °C with mains voltage tolerances of +/- 20% Advantages of degaussing: — No deflection of the arc by residual magnetism in the workpiece — Prevention of lack of fusion due to insufficient sidewall fusion — Minimisation of finishing work — Cost-efficient and high-quality results — Set: Degauss 600 degaussing machine, two 5-metre, 35 mm² load cables, one 20-metre, 35 mm² load cable, RT DGS1 remote control and 5-m connection cable

Request for a quote

EWM AG

Germany

— MIG/MAG pulse welding machine with optimised synergic characteristics for welding steel — Pulsed MIG/MAG welding, MIG/MAG welding, MMA welding and gouging — Significantly less spatter formation and therefore less finishing work thanks to the pulse function — Welding with solid wire and flux cored wire — Drive 4X Steel: Connection socket for electrode holder on the wire feeder as standard — Drive 4X Steel D200: Adjustment of the gas quantity directly on the wire feeder via the gas control valve as standard. — Factory-fit option: Extra gas valve for increased safety — Infinitely adjustable arc dynamics (choke effect) — Adjustable start and end-crater functions — Synergic or manual welding operation

Request for a quote

EWM AG

Germany

— Inverter welding machine, DC — Very light-weight, only 4,7 kg – housing made of aluminium and impact-resistant plastic — Portable, shoulder strap — MMA and TIG lift arc welding — Cellulose electrodes: 100% safe for vertical-down welding — Welding of stick electrodes up to 4 mm — Pulsed MMA welding: — Especially suitable for root welding — Outstanding gap bridging with no sagging of the root side — Fine-flaked weld surface with a TIG look for final passes — Less finishing work thanks to less spatter — Ideal for difficult electrodes — Less distortion thanks to controlled heat input — Pulsed TIG welding with up to 2 kHz — Connection capability for remote control — IP23 spray water protected — Arcforce, hot start, antistick — Energy efficient due to standby mode — 3.5 m mains lead with 16 A earthed plug — Overvoltage protection: No damage to machine caused if inadvertently connected to 400-V mains voltage

Request for a quote

EUROLASER GMBH

Germany

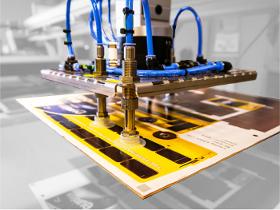

Optimise your production process by automating the supply of your laser system. With our flexibly configurable and scalable robot systems, your jobs will be done quickly and accurately. Fully automated process operation The table already loaded with the new material will be released through a digital signal. Once the working process on the second table is completed, the change will start fully automatically. The new material is cut automatically while the robot will unload the finished work pieces, parallel to the cutting process and without downtimes.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Their flexibility and high performance make BEHRINGER tabletop machines the ideal solution for the medium ton range. The table moves the weight BEHRINGER tabletop machines are ideal for use in forges, rolling mills and die casting factories, in steel finishing works and for tool and mold making. Their individually traversable material clamping vices and blade guide arms make these ideal for cutting bulky materials. The low table height makes this type of machine ideally suited for use on normal hall floor level. BEHRINGER tabletop machines are supplied as standard in semi-automatic form. Automation is possible by upgrading with an additional material clamping vice at the end of the table. Positioning takes place on an axiscontrolled basis. Optionally available is 90° rotatable blade guide for vertical and horizontal sawing to allow notching of materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RHODIUS ABRASIVES GMBH

Germany

Non-woven tool for the quick change system. For fine grinding work. • Uniform surface finish • High proportion of grain binder for long lifetime • Quick tool change without bonding or sliding

RHODIUS ABRASIVES GMBH

Germany

Non-woven tool for the quick change system. For fine grinding work. • Uniform surface finish • High proportion of grain binder for long lifetime • Quick tool change without bonding or sliding

RIGA WOOD GMBH

Germany

Riga HPL Birch plywood ( Riga Ply) overlaid with HPL (High Pressure Laminate) on one or both faces. On the reverse face balance paper can be applied. Overlay HPL is a decorative high-pressure laminate. HPL is made of layers of Kraft paper impregnated with phenol resins (the core) and decorative melamine impregnated paper (the surface layer), manufactured under high pressure and temperature. Colors at customer’s request. Application Furniture industry: kitchen and laboratory furniture components and worktops; furniture for shops. Transport industry and construction: finishing works of walls and ceiling, surfaces where high wear resistance and appearance are required. Sizes 1220 mm x 2400 / 3050 mm 1250 mm x 2500 / 3000 mm Cut-to-size panels, machining and processing up to ready furniture components in accordance with the customers’ requirements. Thicknesses Plywood ( Riga Ply) nominal thickness is 6.5, 9, 12, 15, 18, 21, 24, 27 mm. To Riga Ply thickness the following should be added: 2 x 0,6 mm (HPL thickness), if HPL is applied on both faces 0.6 + 0.15 mm (balance paper thickness), if HPL is applied only on one face

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: EN AW-5754 (AlMg3), 3.3535, H22 Type of production: cold-rolled Condition: work-hardened, annealed, 1/4 hard Surface finish: Mill-finish Standard: EN 573/EN 485 eClass 9.1: 35020501 UNSPSC 11.2: 30102506 Dimensions: Thickness (mm): 0.5 - 6 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000 Foliation: no foil, protection foil, no paper

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: EN AW-5083 (AlMg4,5Mn), 3.3547, H111 Type of manufacture: rolled Condition: annealed, slightly work-hardened Surface finish: Mill-finish Standard: EN 573/EN 485 eClass 9.1: 35020501 UNSPSC 11.2: 30102506 Dimensions: Thickness (mm): 1.5 - 10 Width (mm): 1,000 - 1,500 Length (mm): 2,000 - 3,000

Request for a quoteResults for

Finishing work - Import exportNumber of results

11 ProductsCountries

Company type