- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- labelling device

Results for

Labelling device - Import export

RIEDEL COMMUNICATIONS GMBH & CO. KG

Germany

RockWorks is a real-time management system for RockNet and enhances the remote operation of complex widespread networks. Each RockNet device can be monitored and con gured on screen according to the front panel operation. RockWorks enables labeling of each device and channel within the network. The software provides alarm indications and allows for a network- wide default reset of channel parameters and naming. For a more comfortable setup, RockWorks also features an offline editor. RockWorks MY Card Preset Dialog The RockWorks preset dialog provides full access to RockNet MY interface card presets and allows for the individual configuration of emulation mode, channel routing, microphone pre-amp count (RN.301.MI/RN.101.IO) as well as sync master settings. A total of 15 presets (1...9, A...F) can be configured. Presets are activated by using the rotary switch on the front panel of the RockNet MY cards. In order to enable maximum flexibility in routing, the number of dropped...

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-TS two sides labeling machine is Mostly applicable for square, flat bottles, round containers for medicine, daily chemical, cosmetics, food cultural supplies, Electronic and etc. Advantages: 1. PLC CONTROL, Automatically check the length of labels 2. Equipped with warning device of insufficient labels, broken labels 3. No bottle, no labeling 4. No labels, no labeling 5.Servo motor control, stable labeling

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

it is widely application for the container pasting with two front and back labels, it is one type of self adhesive labeling machine, single and double side labeling is option, using for round container, square and flat container, also carton, boxes ,ect. It is automatic controlled by PLC easy operating. It can change specifications easily. It adopts servo motor, achieved closed loop control low malfunction rate. High efficiency. Double sides labeler we also call it as front and back labeling machine, for it is pasting two labels front and back. Advantages: 1. PLC CONTROL, Automatically check the length of labels 2. Equipped with warning device of insufficient labels, broken labels 3. No bottle, no labeling 4. No labels, no labeling 5.Servo motor control, stable labeling

Request for a quote

AXRO BÜROKOMMUNIKATION DISTRIBUTION IMPORT EXPORT GMBH

Germany

Special features: Inkjet, 11.1 V Li-Ion, Up to 4 imprints can be saved

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

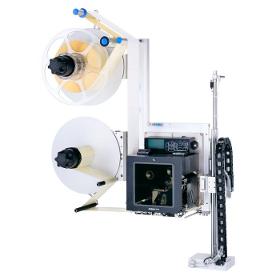

The requirements for product labelling are increasing and becoming more and more diverse. Track and Trace, product tracing, quality assurance, GS1 regulations require secure and reliable application of variable data. This applies to almost all industries, whether logistics, pharmaceuticals, food industry or chemicals such as agrochemicals. When printing variable data such as graphics or Data Matrix, barcodes, QR codes and comparable code types, uncompromising quality must be implemented. The EDS 420i and EDS 620i printing and dispensing systems are designed for industrial use and enable you to label your products and their packaging precisely, reliably and quickly using different applicators and label transfer modules. The modular design of the systems was the main focus in the development of the printing and dispensing systems

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

The sterilization documentation system is used for patientrelated traceability of all medical sterilization processes. The documentation page contains all the necessary information to release the sterilization batch. One sterilizer and one documentation sheet for the day are used. Using a labeling device (Label Gun), the documentation sheet and each package can be labeled with a selfadhesive label containing the following information • Production and expiry date, •Person in charge, • The contents of the packaging, • Sterilizer and batch number. All packages on the lot and documentation pages have the same label content and lot number. After opening the sterile package in the OR, the top layer of the label can be peeled off and affixed to patient and/or operative documentation. The content of the label allows for followup on the patient's return to batchrelated documentation in the sterilization department.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This front table is ideal for preventing the packages from being damaged or torn by rubbing against the table during the packaging of the products in the devices.. • Cut pouches do not mix with each other. • When the cutting is finished, the pouches are easily put into a bag or wrapped with paper tape. • In order to prevent the paper tape from being opened (in 40GM model device), a label taken from the thermal printer and containing the desired information is attached. • The connected pouches that are put into stock do not scatter or get lost, information such as which product/set they belong to and their number, LOT number, etc. can be seen. • If a Barcode is defined for the products, all the ties in the stock can be counted very easily thanks to the Barcodes printed on the label. • It is AISI 304 stainless steel. • Dimension (L x W x H) 563 x 274 x 67 mm • Weight 2.8 Kg • Designed for 28GM, 30GM and 40GM model Pouch Making Sealers.

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Our OEM print modules DPM and PEM are the excellent answer to today’s high Print & Apply demands. These modules generate great flexibility in developing a tailored Print & Apply Solution. The DPM and PEM modulesprovide precise, safe printing and labeling for industries such as food, chemical and pharmaceutical and integrate seamlessly into production lines. As an engineering company or system integrator, you know your customers expect you to provide complete labeling devices tailored to their requirements.The Dispensing Print Modules (DPM) and Print Engine Modules (PEM) provide precise, safe printing and labeling for industries such as food, chemical and pharmaceutical and integrate seamlessly into most production lines.

Request for a quote

ASTRONOVA GMBH

Germany

The QL-120X establishes a new standard in color labeling: It features the industry’s best two-year warranty, coupled with our second-generation printhead technology and eXtended life delivering 3X more labels than the original QL-120, while still featuring four individual, user-replaceable printheads for rapid on-site changeover eliminating printer exchange downtime, and costly refurbishment charges. High-performance dye ink provides true-to-life colors using industry-standard ICC color profiles. Flexible integration options of external labeling/packaging devices. Time-tested design proven to deliver years of reliable service for the most critical product labeling applications. Flexible integration possibilities with external labeling and packaging devices through the control and command language.

Request for a quote

HERMA GMBH

Germany

You want safety when it matters? The HERMA PA4 / PA6 (Print & Apply) is the ideal device for all users who require durable and hard industrial use and ensures smooth operation and reliable labeling. This print & apply system offers you versatile possibilities. Print resolutions of 200, 300 and 600 dpi ensure maximum readability of the printed image. Standard components from the HERMA modular system guarantee quick and accurate label dispensing. The devices can be positioned in any orientation and offer many options for integration into existing production lines.

Request for a quoteResults for

Labelling device - Import exportNumber of results

11 ProductsCountries

Company type