- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- maintenance of lifts

Results for

Maintenance of lifts - Import export

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

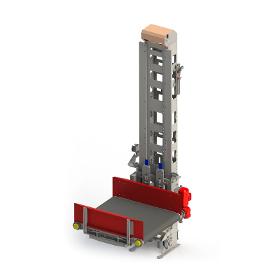

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Unique and light as a dragonfly – this is how the Motion06 Inclined Transport Unit works – quickly and safely overcoming any height difference. The inclined conveyor transports flight baggage directly to the passenger boarding bridge, meaning it can be used in direct proximity to the aircraft. Baggage or similar general cargo is either safely lifted onto the aircraft or lowered onto the apron. Staff must no longer carry the baggage up and down the sometimes wet or icy stairs in any weather. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation. Efficient Energyefficient and economic design. UltraSimple Adjustment Ultrasimple adjustment to required installation conditions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

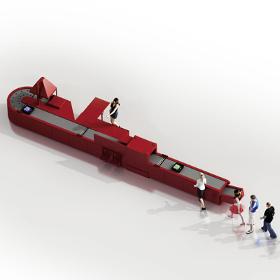

The Motion06 Hand Baggage Control Unit conforms to the latest standard of technology and requires minimal staff involvement for handling. The defined field of use is automated hand baggage transportation into containers with automatic container return. This keeps the manual handling of the containers to a minimum. The security personnel can focus entirely on checking passengers and baggage. UltraSimple Adjustments Ultrasimple adjustment to required installation conditions with modular system Universal Compatibility Can be combined with all conventional XRay machines. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

KEDY

Turkey

Manual All controls are made by the operator via the control button. Each crane is controlled by an operator. Semiautomatic H Busbars are an automatic transport system from the unloading area to the loading area. The system is suitable for automatic operation. Transitions between stations are made by operator control. Waiting and immersion times are automatic in the boilers. Automatic operation when necessary, but in case of failure, intervention with external operators, transitions between boilers are made by the operator. Fully Automatic The whole process is controlled from the skada screen. There is no need for an operator at the beginning of the cranes. All boiler chemical controls are made automatically from the skada screen. Transitions between stations are made automatically to unloading stations. It has the possibility of easy maintenance and intervention with remote access. Lifting drive is with chain gear system and it is supported by rollers on the guide rail

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LANGHAMMER GMBH

Germany

Advantages • High uptimes due to maintenance-free guidance of the main axes • Low headroom with telescoping axis/option • Handling of very heavy loads with rigid Z-axis/option • Highly flexible due to the use of a variety of grippers • Interleaf + pallet handling possible The Gantry Robots can be used for almost all products such as bundles, boxes, bags, standard cases, bakery baskets and packs. Equipped with a maintenance-free axis system, strong lifting axis or telescopic lifting axis they are predestined for heavy-duty usage. What characterizes our gantry robots is their high flexibility, wide operating range and precision in handling. They meet the requirements needed for increasing the variety of handled products. In this way unit costs are optimized and processing safety heightened. The system's flexibility increases the machine's uptime and makes it possible to react faster to market requests. These robots offer a flexible, reliable and economical automatic solution.

Request for a quoteResults for

Maintenance of lifts - Import exportNumber of results

7 ProductsCountries

Company type