- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- woodworking - machinery and equipment

Results for

Woodworking - machinery and equipment - Import export

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola GAMA 80 V carpenter’s circular saw bench for professional applications Equipment / scope of supply- Motor rating 22 kW (P1) / 400 Vac-50 Hz star delta start gear drive - Motor speed rpm 3.000 / sawblade speed rpm 2.200 - Cutting height 90° / 310 mm – 45° / 217 mm – 30° / 149 mm - Electrical sawblade inclination 90 – 30° - Revolving table 0-270° - Machine table with lateral movement 650 mm - Automatic vertical pneumatic clamping cylinders right / left - Laser light for cross cutting - TCT-sawblade, 800 x 30 x T90 - Dust extraction spigots 160 / 160 / 80 / 80 mm - Sawblade height adjustment via mechanical stop system, with measuring scale, easy to adjust - DUO infeed / outfeed devices

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

LATERALLY MOVABLE UNDERTABLE CROSS-CUT SAW / RIP CUT SAW FULLY AUTOMATIC CIRCULAR SAW FOR POSITIONING AND CONTROLLING VIA TOUCHSCREEN WITH LENGTH MEASURING SYSTEM EXENSO COMFORT (PUSHER SYSTEM) Application : Length stop system (pusher operation), revolving table with lateral movement and sawblade inclination via servo - motor for positioning (rip cut, cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Equipment / scope of supply : - Motor rating 12 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - lateral movement of machine table 400 mm with pneumatic brake system - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Cutting height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT - sawblade 650 x 30 x T 54

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The newly developed RUF Briklet press produces briquettes with a diameter of 30mm. The Briklet is the right choice, when a small briquette size is needed. Therefore they can be conveyed with an automatic feed. Furthermore, it automatically offsets varying grain sizes so that other materials apart from wood can be processed effortlessly. With wood chips, the RUF Briklet press can achieve a throughput rate of around 300 kg/h with a briquette density of ≥ 1 kg/l.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

For every need a suitable press: All briquetting systems of the RUF LIGNUM series process residual wood at a constantly high level of quality and density – from dust to wood shavings and coarse chips. The remaining water content must be less than 15% in order to create briquettes with consistent quality and thickness. For every requirement the right format: The rectangular briquettes can therefore be perfectly stacked and bundled into packages . The briquette formats 150x60mm and 40x70mm are available. Optimized throughput rates with our LIGNUM series: All RUF LIGNUM models are highly energy effi cient thanks to their innovative RUF hydraulic system. The further improvement of the hydraulic system of the LIGNUM R2 and LIGNUM R4 has led to an effi ciency increase of around 25%. Briquetter for wood have depending on model & material throughput rates between 410and 1,050 kg/hr.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The RUF SZ1+ briquetting system presses loose wood chips into compact briquettes. The high pressure ensures a constant high quality and density. As an entrylevel model of our wood presses, the SZ1+ is available in a standard design with proven RUF technology for small capacities (30 – 60 kg/hour). Benefits: Compact design Low wear Plug-in ready at delivery Easy operation with touchpanel Wide spectrum of additional compressible materials (wood, paper, styrofoam, ...) Automatic feeding of briquettes to industrial combustion plants possible

Request for a quote

FRANCKE-ART

Poland

We offer high-quality woodworking. We make tabletops made of solid oak, pine, in wholesale quantities. Oiled or varnished. Thickness and dimensions to be determined.

Request for a quote

BIESSE UK

United Kingdom

K60 Trim is a compact semi-automatic edge trimming machine which performs the edge trimming applied on straight and shaped panels.

BIESSE UK

United Kingdom

Blaze 120 is the hydraulic hot press for pressing laminates, veneer onto mdf, plywood and chipboard.

BIESSE UK

United Kingdom

WinLine 16 is Biesse's new NC multi-centre for the production of doors and windows, designed for artisans and small industries aiming to increase production and for medium and large industries who need to produce small batches of unusual size or remakes. The system produces both standard and special doors and windows with the utmost simplicity while the operator handles other tasks; the machine only takes up a small area and handles the loading, unloading and positioning of pieces autonomously and with extreme precision.

BIESSE UK

United Kingdom

Rover Edge Line is an innovative production line, unique to the industry, for the high volume production of edgebanded curved panels. This solution enables greater quantities of panels to be produced using fewer machines and therefore fewer operators.

BIESSE UK

United Kingdom

Opera 7 is a finishing centre designed for large enterprises that enables processing operations to be performed using high-productivity automatic production systems, ensuring constant performance quality.

BIESSE UK

United Kingdom

The Cosmo electromechanical clamp is the ideal solution for meeting all assembly needs for furniture both for the artisan and in the made-to-measure production departments of the industry.

DECK ART MACHINES

Serbia

Introducing Deck Art Automated Parquet Finishing Solutions, where innovation meets efficiency. Our cutting-edge technologies guarantee impressive output capacities, low power consumption, zero material waste, and environmental friendliness. Embrace automation and the Industry 4.0 concept for optimized efficiency and superior product quality. By integrating our advanced machines into your production line, you'll save money while ensuring exceptional finished results. Our team is ready to provide unique support and tailor the best possible solutions to your specific needs. Contact us today to share your ideas and embark on a transformative journey. Discover the power of Deck Art Automated Wood Flooring Finishing Solutions.

Request for a quote

DECK ART MACHINES

Serbia

Unique Cold Hydraulic Presses Specially Designed for Engineered Wood Flooring (Parquet) Production https://www.deckart-machines.com/ Now with an updated design and new special features included in our third generation, MK3 series presses: - Complete digital control by 15’’ touch screen. - Digital pressure monitoring system for each gluing cycle. - Automatic adding of pressure for each gluing cycle. - Digitally adjustable pressing time of each gluing cycle. - Automatic release of the pressing plates for each gluing cycle. - All of the presses are equipped with a motorized conveyor system for delivering the material from the glue spreading machine to the working spot on the press. The transport speed of the material is digitally controlled. - All of the presses come with multiple independent gluing cycles in combination with a stop valve on each hydraulic cylinder. This feature enables yo

Request for a quote

MASCOTT ARS LTD

Belarus

The machine is the first row. It is intended for longitudinal sawing of logs on 2-edged beams and slabs. Technical specifications Min / max. log length, mm2000-7000 Min / max. log diameter, mm140-600 (in the stone) Diameter of the saw blades, mm, 2pcs.1200 Shaft diameter, mm70 Number of turns per shaft800 Feed rate, m / min1-30 Power of electric motors with oil station, kW80.5 Input performance, m3 / per hour15-30 Length of the feed table, mm7500 Machine dimensions, mm length without a serving table2600 height 1700 width1200 Weight without a serving table 2950

Request for a quote

MASCOTT ARS LTD

Belarus

Circular is designed for sawing 2-ply timber on edged sawn timber with an accuracy of 0.5 mm and slab trimming on three sides.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BENZ GMBH WERKZEUGSYSTEME

Germany

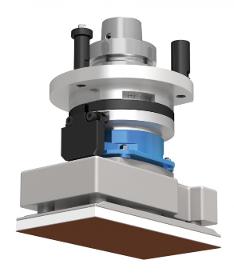

Sanding of surfaces with internal corners ≥90 °: ZUCCO vibrating sanding unit With the SIMOLO eccentric sanding unit, BENZ already has a range with high sanding performance and surface quality, especially for machining small to medium-sized surfaces. With the new ZUCCO vibratory sanding unit sanding surfaces with internal corners ≥ 90 ° is possible. The eccentric movement of the unit ensures uniform workpiece surfaces. As abrasives, commercially available products can be used. Abrasive blanks can be attached to the sanding plate via a hook and loop fastener. These options provide the user with the greatest possible flexibility.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Chiseling – Square. Practical. Precise. Typical applications for chiseling processes are stake holes on steps for mounting a handrail or inserting fiche hinges in window processing. Whether hard or soft wood, CNC chiseling units help you achieve precise, square cutouts.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

It‘s a situation you know. You run your hand over a piece of furniture and appreciate its shape under your fingertips. One surface feels rough, another feels fine and smooth. There‘s only one thing that can deliver this distinctive feeling: the perfect sanding pattern. BENZ sanding units make sure that your workpiece gets the exactly right surface, for every shape and surface. Your benefit from machine CNC sanding: no more need for time-consuming clamping for further processing or manual rework. Your production process is streamlined and your production costs are reduced as a result.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quoteResults for

Woodworking - machinery and equipment - Import exportNumber of results

153 ProductsCountries

Company type

Category

- Woodworking - machinery and equipment (42)

- Milking - machinery and equipment (18)

- Axles, vehicle (18)

- Bakery - machinery and equipment (17)

- Flour milling - machinery and equipment (16)

- Bakery - machinery and equipment (12)

- Food industry - machinery and equipment (9)

- Textile dyeing (9)

- Textile dyeing - machinery and equipment (9)

- Confectionery - machinery and equipment (7)

- Painting machinery and equipment (7)

- Mining and quarrying - machinery and equipment (5)

- Lubrication equipment and machinery (5)

- Packing and packaging - machinery and equipment (5)

- Brewing - machinery and equipment (4)

- Harvesting machinery and equipment (4)

- Sawmills - machinery and equipment (4)

- Bottling and filling - machinery and equipment (3)

- Beverage industry - machinery and equipment (2)

- Brick-making - machinery and equipment (2)