- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- measurement and regulation equipment and instruments - temperature

Results for

Measurement and regulation equipment and instruments - temperature - Import export

TROTEC GMBH

Germany

Technichal data: Accuracy ± 3°C at -50°C to 20°C ± 1% or 1°C at 20°C to 500°C ± 1.5% or 2°C at 500°C to 1,000°C ± 2% at 1,000°C to 1,850°C Reproducibility ± 1.5°C at -50°C to 20°C ± 0.5% or ± 0.5°C at 20 °C to 1,000 °C ± 1% at 1,000°C to 1,850 °C Optical resolution (D:S): 75:1 Smallest measurement spot: 18 mm @ 1,350 mm Temperature range: -50°C to +1,850°C Reaction time: < 150 ms Spectral sensivity: 8 ~ 14 µm Laser class: Klasse 2 (II) Wavelength: 630 ~ 670 nm Power: <1 mW Display: LCD, monochrome Temperature range (contact-temperature sensor): 50°C to +300°C Accuracy (contact-temperature sensor): ±1,5% or ± 3°C Reproducibility (contact-temperature sensor): ± 1,5% Operating conditions (operation): 0°C to 50°C, 10% to 90% RH Operating conditions (storage): -10°C to 60°C, < 80% RH (non-condensing) Power supply (internal): 9 V IEC 6LR61 Power supply (external): via USB

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Temperature measuring strips, for example, are stuck to components that heat up under load. The measuring strip shows the maximum temperature reached after the component has cooled down. This means that the maximum temperature of the component can be read off quickly and inexpensively.

Request for a quote

FRIGOFLUID S.R.L.

Italy

FT water temperature controllers make it possible not only to cut down on the use of electrical power for heating (in fact, the heating elements remain off during steady-state operation), but they also make it possible to limit the cooling power spent on cooling by self-stabilizing through a process called Autotuning. This system also saves resources (water and energy) compared to units without them. They are designed to condition molds and cylinders for various industrial processes, including plastics and rubber molding and extrusion, and in the paper industry.

Request for a quote

FRIGOFLUID S.R.L.

Italy

Often the main critical issue for molding industries is not achieving the temperatures needed for their processes, but maintaining them over time. Hence the usefulness of temperature control units that not only send the fluids needed to do the job up to temperature, but are capable of subsequent self-tuning. This is the way FTT DC water temperature controllers operate, which wrap direct cooling to stabilize fluid grades after the desired temperature has been reached. This requires integration with a source of cooled water: a simple well or a chiller or cooling system (chiller or dry cooler). Our engineers are available to determine which cooling solution is the most effective and economical. Not only that. The management of these successive heating-cooling steps is easier when done with a touch screen: a feature with which FTT DC temperature controllers are equipped. Units in the FTT category are specially designed to condition molds.

Request for a quote

FRIGOFLUID S.R.L.

Italy

Most industrial process temperature control units work through the pressure exerted on the water of the process utilities: this is convenient in most “standard” cases, given the higher efficiency developed by the system. However, some critical process issues can make this type of operation difficult: this is the case of machines that leak fluids, or with leakage, and that it is not convenient to maintain on the spot. In such cases, it is therefore useful to work with a vacuum temperature control unit, which sucks in utility water. FTT PD water thermoregulators are flexible and effective systems, which can work under either pressure or vacuum depending on the peculiarities of the system. Any fluid losses are therefore minimized during operations. A simplicity of operation is also ensured by the touch-screen panel, also found on other Frigofluid temperature controllers. Models with an increased pump are also available for users characterized by high pressure drops.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Dedicated temperature profiling solutions for — Anti-reflection coating & Thin-film deposition — Silicon PV manufacturing: contact drying, contact firing — Lamination Benefits — Measure product temperature uniformity across the process chamber(s) — Optimize the process by reducing energy costs and/or increasing throughput — Troubleshoot the process quickly and easily — Track process stability

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

• Real-time thermal imaging, scan speed up to 300 Hz • Up to 1024 measurement points per line • Wide choice of spectral and temperature ranges • High-quality brushless motor (MTBF 40,000 h) • Built-in Ethernet TCP/IP communications • PC independent alarm output • PC independent 4-20 mA interfaces (3 outputs) • I/O module support for up to 10 sectors/zones (PC independent) • Internal Line Laser for accurate alignment • Rugged, waterproof IP65 enclosure • Air purge keeps window free of dirt and condensation • Built-in water cooling for ambient up to 180 °C (356 °F)

Request for a quote

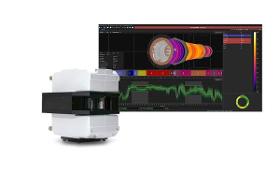

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: — Polar charts highlighting coating thickness and brick thickness — Envelope profiles – including alarm functionality – over the entire kiln — Built-in, on-network storage to store historical data — Free scalable AOIs (areas, line and slice) including temperature trend analysis — Virtual 3D walkthroughs across the entire kiln — 3D views available per each defined kiln zone — Easy-to-use software configurations that showcase the scanner position relative to the kiln — Flexible image sizing and configurable orientations of rotation — Fail-safe “hot spot” alarm outputs

Request for a quote

NOVOSIM

Turkey

End-of-Line (EoL) testing devices are used to test the quality of the product after the production process. The purpose of the testing system is to check any visual, audio or other problems that may arise during the installation and assembly of components before they are delivered to customers. Application examples of end-of-line testing systems developed by Novosim include: Rotary systems (transmissions, axles, etc.) Automotive Component Testing Noise and vibration level measurements special systems EoL testing systems are complex systems that generally operate automatically and include a range of sensors, data acquisition devices and testing equipment. Test procedures can be prepared in the form of predefined scenarios by the development team and stored in a database. Different scenarios can be prepared for different test conditions (high speed, low speed, long term, short term, etc.) and then called from the database.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

The award-winning smart temperature probe with integrated HART® transmitter and Heartbeat Technology features the world’s first RTD sensor unit capable of fully automated in-situ self-calibration. It effectively eliminates the risk of undetected non-conformities, reduces production downtime and increases product safety and process efficiency in applications of the food & beverage and life sciences industries. The device is fully compliant to FDA 21 CFR Part 11 regulations and GMP rules.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

The compact thermometer measures the process temperature using a Pt100 sensor element (Class A, 4-wire). An optional integrated transmitter converts the Pt100 input signal. In the version with integrated electronics, the device automatically detects the connection variant (IO-Link or 4–20 mA).

Request for a quote

ENDRESS+HAUSER AG

Switzerland

The iTHERM TMS31 is a versatile, modular multipoint temperature assembly designed for temperature average detection and profiling in grain, organic bulk material storage silos and in oil, fuel storage tanks., The device’s mechanical robustness and accurate temperature sensors offer the necessary characteristics for safe, reliable and economic product storage operations. In its standard configuration it is available with up to 20 thermocouple (TC) or RTD sensors fitted to a primary metal rope.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

Specially designed for applications where small size of the probe and light weight are crucial. The TMS21 can be highly customized due to its versatility. It can monitor the temperature on a very high number of points along a line just by using one process connection. It is composed of several low diameters thermocouples protected by one overall primary tube thermowell. Two different product configurations are available, with or without flexible upper thermowell-hose (for axial centering).

Request for a quote

ENDRESS+HAUSER AG

Switzerland

Unsurpassed reliability, accuracy and long-term stability in critical processes across all industries. The configurable transmitter transfers converted signals from RTD and thermocouple (TC) temperature probes, as well as resistance and voltage signals using HART, communication. Diagnostics information according to NAMUR NE 107. Seamless integration into all major control and asset management systems. Integrated Bluetooth, interface for remote operation via Endress+Hauser SmartBlue App.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

Unsurpassed reliability, accuracy and long-term stability in critical processes across all industries. The configurable transmitter transfers converted signals from RTD and thermocouple (TC) temperature probes, as well as resistance and voltage signals. The standardized 4 to 20 mA output signal is used for process measurement. Swift and easy commissioning, operation and maintenance via PC software or with integrated Bluetooth, technology and Endress+Hauser SmartBlue App.

Request for a quote

CAMILLE BAUER METRAWATT AG

Switzerland

• Programmable without any power supply connection • Zero and span calibration via software • Suitable for temperature measurement in hazardous areas • Sensor breakage and short-circuit monitoring

Request for a quote

WINTERS INSTRUMENTS

United Kingdom

- A general purpose, versatile 1” (25mm) to 6” (150mm) dial, 304 stainless steel thermometer - Bi-metallic sensing element for reliable readings - Back, bottom or adjustable angle connection - Welded stem length from 2.5” (63mm) and up - ±1% accuracy - Anti-parallax dial that reduces operator reading errors (3” (75mm)–6” (150mm)) - Recalibrator screw is standard on all dial sizes - ASME B40.200 compliant - RoHS compliant - 5 year warranty

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

Temperature control units started 1 up to 64 zones, Soft start stop options Manual or automatic switchable Smart selfoptimisation

Request for a quoteResults for

Measurement and regulation equipment and instruments - temperature - Import exportNumber of results

19 ProductsCompany type