- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic devices

Results for

Pneumatic devices - Import export

FERPLAST SNC

Italy

PNEUMATIC CENTERING DEVICE WITH MOTORIZED ROLLERS (MOD. CP-FM) MANUFACTURERS VERSION Feeder - centering device useful for centering boxes max width mm. 650 and max weight kg. 50. Can be combined with automatic taping and labeling machines. The box centering machine mod. CP-FM consists of a motorized roller conveyor and two pneumatically operated side guides. The metal parts are painted with epoxy powder while the other components are galvanized. The pneumatic centering device with motorized rollers is a module for builders to be completed and adapted to an automatic line. It is available in two versions: Manufacturers version and "plug and play" version: In the "manufacturers" version, the centering device is supplied complete with: - Motorized roller conveyor with start and stop button and emergency mushroom, at a fixed speed of 15 meters / minute - Pneumatic tail lifts and compressed air system up to the gate movement management valve.

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC TURNING DEVICE WITH FREE ROLLERS 90F MODEL. DIVERT BOXES BY 90°. Pneumatic turning device with free rollers conveyor, complete of stop barrier including sensor and pneumatic pusher with cylinder of 50 mm for expulsion of boxes at 90°. The metal structure is painted while the other components is provided with galvanized finish. The pneumatic pusher is activated by a box hitting the stop barrier, changing its direction of 90°. Usually it used in cascading lines.

Request for a quote

FERPLAST SNC

Italy

BSL 5045 SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Angular packaging machines with manual or automatic closing of the sealing bar and motorized product unloading belt. They can be combined with a retraction tunnel. FEATURES: - Sealing blade in NI-CR with non-stick coating - Control of the welding time to avoid overheating - Conveyor belt adjustable in height by handwheel - Double magnet for high closing force - Reel holder sliding on ball bearing guides, useful width mm. 550 - Return of the sealing bar controlled by a gas spring (for the 5045 L manual version) - Pneumatic device (compressed air) for closing and opening the sealing bar (for the BSL 5045 LA semi-automatic version) The BSL 5045 LA model is equipped with a maintained action dual control (the two buttons must be held down until the bars are completely closed).

Request for a quote

FERPLAST SNC

Italy

BS 8060 LINE SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Large angular packaging machines with manual or automatic closing of the sealing bar and motorized carpet for product discharge. This machines are capable of packaging bulky products using any type of single-folded film reel (PE-PP-PVC). The package is sealed on all sides, and if you want a thermo retracted packaging, the machine can be matched to the powerful tunnel BS 5540 M. Features: NI-CR sealing blade with non-stick coating Sealing time control to avoid overheating Adjustable conveyor height by handwheel Double magnet for a high closing force Reel sliding on recirculating ball guides, useful width mm. 750 Return of the sealing bar controlled by a gas spring (for manual version BS 8060L) Pneumatic device (compressed air) for closing and opening the sealing bar (for the semi-automatic version BS 8060LA)

Request for a quote

FERPLAST SNC

Italy

CJS 25 HI is an electronic dosing device with load cells for semi-automatic filling of bags with max weight 25 kg. Hopper capacity 300 l, bags weight 2-25 kg. The machine is suitable for the automatic dosage of granular products with a good flowability. The dispenser is mainly formed by a welded and painted tubular steel, stainless steel, loading hopper with pneumatic closing, fast discharge channel, slow discharge channel with vibrator to achieve the exact weight, weighing hopper installed on load cells, pneumatic device for locking the empty bag, PLC operator interface and user-friendly keyboard. The dispenser can be combined with a motorized conveyor for automatic loading of the product and to a free or motorized conveyor for unloading the full bag, it can also be combinated with an automatic packaging machine. All parts in contact with the product are made of stainless steel. Ideal for packaging of pellets, granulated foods, dried pasta (short), cereals, coffee, nuts, sugar, etc.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

width 76 cm age 2016 mobile stacking system for markfree delivery bundling delivery with max. 3 use pneumatic pressing station jogging device max. width 760 mm - 1 up max. width 235 mm - 3 up max. 600 packages / hour Delivery time: immediately from stock Ref: PA230285A Please ask for price. We ship and install worldwide!

Request for a quote

PRESSTA EISELE GMBH

Germany

Drive 7,5 kW, S 6, 400 V, 50 Hz, R.P.M. of sawblade infinitely adjustable (2.000 – 3.500 R.P.M.) Sawblade Ø 500mm, smaller blades on request Cutting range max. 215 x 120mm (height x width) Hydro pneumatic saw blade feed, Speed infinitely adjustable, linearly under the tabletop from rear to front Material fence on the table for the cutting angle Feed length limited via 4 end switch horizontal profile clamping device on the feed and discharge side Cycle spray mist device Pusher Profile feed from right to left with ball screw and servo motor Feed length from 10 to 2500 mm Feed speed max. 250 mm / sec. Repeatability +/- 0.1 mm iincl. horizontal pneumatic clamping device Reversing possible, max. Stroke length 7,300 mm Siemens S7-300 with touch screen 10“

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Together with the Fachhochschule Münster – University of Applied Sciences we are working on ALWA PERM (patent No. 2583995). This is a metal-filled casting resin for producing a porous, resin-bound mould. These materials are applicable in the areas of thermoforming, the ceramic industry, intake moulds and devices, pneumatic cushioning, the filter industry, etc. ALWA PERM allows a castable production of porous metallic materials with a binder for the first time. The system offers a highly accurate mould surface reproduction. The profile characteristics goes far beyond the current state of the art. NO MORE DRILLING OF VACUUM HOLES! NO DAMAGE OF THE MOULD SURFACE DUE TO DRILLING HOLES

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

Working range 6.4 lock bolts MagnaGrip®* and C6L®* Technical data Weight: 2.6 kg Operating air pressure: 5-7 bar Air hose connection: 6 mm Ø (1/4“) Air consumption: approx. 4.8 NL per rivet Setting force: 23,000 N at 6 bar Stroke: 19 mm Accessoires Angle head with nosepiece in working position Tag on device head 1 hydraulic oil bottle 100 ml 1 oil refill can Operating instructions with spare parts list Advantages • Hydro-pneumatic lock bolt setting device • Accessibility in tight working spaces • Light and compact design • Modular structure • Ergonomic handling

Request for a quote

AHP PLASTIK MAKINA

Turkey

Computercontrolled (CNC) test bar milling machine with installed machining programs and special clamping devices will prepare samples for tensile tests and other specific shaped sample required tests The CNC milling machine is a tabletop unit with protective doors. Preconfigured machining programs for all common sample shapes The allround enclosure ensures safety at the workstation The milling machine is optionally fitted with pneumatic clamping devices Test samples with a maximum length of 250 mm, a maximum thickness of 50 mm can be milled as standard. Optionally thickness of 100 mm is available. Delivered with workbench Test samples milled in accordance with standard dimensions Machined areas cooling with compressed air Highquality unit components guarantee long service time

Request for a quote

ROTORSTECH

Slovakia

These compressors are designed to produce the compressed air required to power the brake and other pneumatic systems and devices of rolling stock of railway transport. •High efficiency and productivity. •Excellent price/quality ratio. •Long period of use •Ease of maintenance •Low lube oil consumption Basic delivery set: Compressor Heat exchangers Fan Safety valves Driven half-coupling Air filter Spare parts kit

Request for a quote

MOSCA GMBH

Germany

Modular construction High-end Standard 6 sealing unit Narrow sealing unit with ultrasonic sealing system Pneumatic hold-down device Pneumatic side pusher with opposite buffer plate Signal exchange via 16-pin contact Easy accessibility and tool-free disassembly of strap path components Low-wear DC drives with integrated electronics Stepless turnable operation panel (ECOB) for many-sided operation Adjustable strap tension via operation panel Programmable strap tension value Switching from maximum to material-friendly Eco-speed in the control Cycle counter integrated in the control Quick strap coil change Strap coil changeable from the front and the side Automatic strap threading system Strap end detection with ejection of remaining strap Automatic strap loop ejection Extremely low energy consumption Stand-by mode 4 castors, 2 of them lockable CE marking inclusive conformity declaration Structural painture in RAL 5010, gentian blue

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Are you tired of losing so much time due to change-over on your machining center? Then we have something for you. The DockLock zero-point clamping system in the hydraulic or pneumatic version. One clamping device quick change-over system for stationary applications. It allows you to change your clamping devices in two minutes. And with repeatability of ≤0.005 mm, without alignment. A special feature: form fit clamping with a collet or clamping segments. That means a rigid clamping set-up and higher repeatability. This also prevents clamping marks on the clamping bolt as opposed to zero-point clamping systems with balls or sliders, which lead to inaccuracies and consequently to replacement of the clamping bolts. Likewise, no contamination and chips can get through, which ensures low-wear operation and reduces maintenance expenses.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • 4 swivel castors, 2 of them are lockable • Strap end detection with ejection of remaining strap • Easy accessibility and tool-free dismantling of strap path components • Easy operation over digital display in the control panel • CE marking inclusive conformity declaration • Extremely low energy consumption [MC] • Flexible foot pedal for manual strap release • Tool-free dismantling of the table plate [TRC] • Potential-free contacts to upstream and downstream machines • Selector switch for single, double or multiple strapping • Infinitely adjustable conveyor speed from 0.1 to 1.0 m/s • Optimization of the strapping processes by machine adaptation to defined package dimensions • Electromechanically driven aluminium rollers ensure an optimal product transport • Tool-free dismantling of roller system • Pneumatic hold-down device with manual prepositioning • Bundle positioning via time

Request for a quote

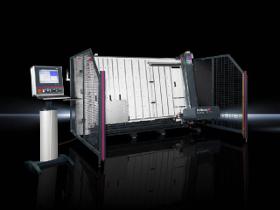

RITTAL

Belgium

Machine equipped with door and pneumatic clamping device. The corresponding support surface enables the machining of cubes up to a maximum depth of 1400 mm. For additional machining of enclosures that cannot be dismantled on Perforex machining centres BC. Machining of cubics f. BC 1001

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For manual grinding work with hand grinders. The grinding tables have an integrated extraction system and work with direct air feedback. Grinding table type ST 20 Three standard working widths are available: 1500, 2000 and 2500 mm. The grinding tables are made of galvanised sheet steel and are painted. The workpieces are supported by a wooden grating with defined gap spacings. The filter elements are located under the wooden grating. Cleaning is performed by a pneumatically driven device. Fan and controller are arranged at the side. A tool support is located above the fan. The grinding tables are also optionally available with work booth and lighting. Equipment Optional versions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or on a fully automatic spraying system, the compact supply tank with its 45 litre stainless steel tank is suitable for all tasks. Equipped as standard with a pneumatic lifting device, handling is particularly easy. By using proven components, the sprayer is perfectly suited for long-term use. The device is suitable for spraying lubricants or coatings with a high solid content. To change the container or clean it, the complete container cover with all attachments is lifted pneumatically.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or on a fully automatic robot spraying system, the compact supply tank with its 45 litre stainless steel tank is suitable for all tasks. Equipped as standard with a pneumatic lifting device, handling is particularly easy. By using proven components, the sprayer is perfectly suited for continuous operation. The device is suitable for spraying lubricants or coatings with a high solid content. To change the tank or clean it, the complete tank cover with all attachments is lifted pneumatically.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

Marks cables 10 to 220 mm in diameter. Marking by means of engraved, concave marking wheels matching the cable diameter. Marking wheels mounted on toe bearings on two horizontally and vertically adjustable swivel arms. The embossing pressure is adjustable by means of a pneumatic device with fine pressure regulator. Hose connection for marking wheel-cooling system that prevents hot insulation material from sticking to the marking wheel type area. A water-collecting tub is arranged below the embossing wheels. SPECIFICATIONS Max. printing speed: 100 m/min Product diameter: 10 mm to 220 mm Marking wheels: 121 mm in diameter (groove bottom) ACCESSORIES Marking wheels Pressure rolls

Request for a quote

MIXACO MASCHINENBAU

Germany

By means of the moveable container with the mixed material, container with separate trolley, will be positioned in the tumbling mixer. The moveable container will be lifted by a pneumatic stamp. The trolley will be fixed in the tumbling mixer by means of a pneumatically actuated draw-in device. The head of the tumbling mixer formed as a container, fixed on the mixing head with four pneumatically operated clamping jaws including forklift pockets and discharge valve. The lifted container is locked to the tumbling head by means of pneumatically actuated locks. After fixing of the container at the tumbling head a SPS controlled tumbling process starts.

Request for a quote

APEX TOOL GROUP GMBH

Germany

The new Cleco TULMan Electronic Counter is a universal product designed to effectively manage pneumatic tools, allowing users to monitor tool usage, and implement preventative maintenance. The TULMan Electronic Counter enables maintenance intervals or calibration checks to be set based on cycles or run time. A yellow LED light warns when the cycle or run time limits are near, while it turns red when cycle or run time limits have been reached. The electronic counter can also allow users to track tool usage or compare product usage among different operators to improve productivity and processes.

Request for a quote

PNEUFLEX PNEUMATIC CO., LTD

China

Pneumatic fittings - hand valves (shut-off valves, pneumatic valves) are used for turning air pressure on and off for pneumatic devices. The three-ways control hand valve, when closed, discharges the residual pressure from the output side (device). Therefore it assures safety at adjustment or repair of the connected devices. The two-ways control hand valve does not have air discharge mechanism, is suited for air supply to a tank or other devices from which the residual pressure should not be discharged. The two-directional control valve is also suited for the system where vacuum piping is used.

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

High speed walking foot postbed machine LP 1646 XLH Double needle walking foot postbed machine, equipped with an extra large rotating hook with a bobbin diameter of 37 mm. This machine is suitable to work with heavy threads on materials like leather, PE, etc. This machine is specially designed for the production of upholstery used in the furniture industry. The machine is standard supplied with pneumatic center guide and compensating inner presser foot. Standard needle gauge 14 mm. This machine is sold only completely mounted! LP 1646-33 XLH Double needle, extended walking foot postbed machine with 12 mm stitch length, alternating walking foot stroke adjustment by dial and extra large vertical axis hooks with a bobbin diameter of 37 mm. The working space is 33 cm and the machine is equipped with a pneumatic switchable second tension device for optimal sewing results. This machine is suitable to work with heavy threads on materials like leather, PE, etc. This machine is specially...

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

WF 1520 – 33 Series WF 1525-33 AUT – Single needle, walking foot, extended flatbed machine with 9 mm stitch length, alternating walking foot stroke adjustment by dial and large vertical axis hook . The working space is 33 cm and the machine is equipped with electric thread trimmer, pneumatic presser foot lifter and back tack. This machine is also equipped with a pneumatic switchable second tension device for optimal sewing results. WF 1526-33 AUT – Double needle, walking foot, extended flatbed machine with 9 mm stitch length, alternating walking foot stroke adjustment by dial and large vertical axis hooks. The working space is 33 cm and the machine is equipped with electric thread trimmer, pneumatic presser foot lifter and back tack. This machine is also equipped with a pneumatic switchable second tension device for optimal sewing results. Standard needle gauge 8 mm. WF 1520 – 33 Series WF 1525-33 AUT – Single needle, walking foot, extended flatbed machine with 9 mm stitch...

Request for a quotePOUGET

France

USE : For night and into tunnels Works. ADVANTAGES : Wide beam of light on all the Working Zone. The PA-2 Projector is a Self-Contained Unit for 11 Hours of Portable Lighting. Battery : 24 Volts - 28 Ah. Power : 55 Watt - Life 11 hours Dimensions : 550 x 400 x 270 mm - Maxi Height = 2.50 m. Weight : 28 Kg The PA-2 Projector comprises : 1 - Projector Bulb 55 W (Protection Index IP-66) Compact Box bi-component : Shockproof and Waterproof. Supply Voltage 24 V direct current. Spiraled Cable Electronic Ballast Assembly of bulbs without tool. 2 - Telescopic Tripod in aluminium alloy Adjusting from 1.1 to 2.5 m. Pneumatic Cushioning Device With an adjustable Foot in height to balance the gradients. 3 - Supply Unit (Protection Index IP-54) Transport Box in polythene (black). with aluminium lateral Frame 2 Transport Handles 2 x 12 V /28 Ah Dry Batteries 230 V Automatic Charger Function Lights, 3 Steps Load Indicator Integrated Protection Sheet with cover, with Feeder Cable. 4 - Transpo

Request for a quote

EXXENTIS

Switzerland

Porous aluminium is a high porosity noise insulation material / metal. Silencers made of porous aluminium serve for noise reduction / absorbtion for instance in pneumatic systems. When escaping from the pneumatic device into the atmosphere, compressed air causes noise levels that are unpleasant and unhealthy. This problem is solved if the air leaves the pneumatic device via a silencer/muffler. We are happy to offer you customized silencers in different form and shape according to your needs - cylindical silencers, silencers in plate and discs form, industrial silencers and mufflers for different applications. For the manufacturing of Industrial silencers / mufflers made of porous aluminium we do not use any cost-intensive pressing moulds as sinter technology needs, but conventional casting moulds. Our products made of porous aluminium have – thanks to innovative and relative simple manufacturing technology – an excellent quality-price rati

Results for

Pneumatic devices - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (4)

- Compressors (1)

- Connectors, pneumatic (1)

- Control panels - electric (1)

- Conveyor systems (1)

- Finishing and binding - machinery and equipment (1)

- Hydraulic tools (1)

- Industrial tools (1)

- Machine tools - metal machining (1)

- Machine tools, metal machining - parts and accessories (1)

- Metallurgy - machinery and installations (1)

- Optical fibres (1)

- Package sealing machinery (1)

- Plastics - machines and material for industry (1)

- Pneumatic conveyor equipment (1)

- Sawing machine tools (1)

- Weighing and dosing equipment (1)