- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punching machines- plastic

Results for

Punching machines- plastic - Import export

METZNER MASCHINENBAU GMBH

Germany

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Preparation of the material components under vacuum and injection into an evacuated mold.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Perfect closing - clamping machines for the APG technology from HÜBERS. HÜBERS' automatic clamping machines permit the productivity advantages of APG systems to be fully realized. The whole system as well as the mould are easily accessible. They can be tilted and rotated around various axes. This enables the moulds to be inserted by automatic lifting devices.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

STAR high quality bending film / folding foil is a high quality product, which offers best protection for parts and press brake tools on nearly every press brake machine. It is tested and developed under most difficult conditions. Test our high quality bending film / folding foil / antiscratch film and see, how you can protect your press brake tools, your bended parts and save money by saving time and avoiding extra work! Avoid following problems : Scratches imprints marks other problems caused by the direct contact from press brake tool and part extra work to clean the part after having scratches, imprints or marks scratches on press brake tools

Request for a quote

MICRON AMERICA

Turkey

It has been designed and constructed with respect to the pre punch holes to prepare a connecting element assembly, especially for metal plates. These packages are produced in order to order and delivery for approximately 3 4 weeks.

Request for a quote

MICRON AMERICA

Turkey

The frame is made of highly polished steel and the cutting dies are simply pushed in for easy replacement. Replacement cutting tubes are also available.

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date injection molding machine design. For example the construction of clamp pistons tighten centrally and working even without lubrication. Our plastic molding machines have wide column intervals and we provide them with euromap standards. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our plastic injection machine. Same point precision stop is possible with our molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for injection mould changing. Our customer can have almost zero defects, scrap and failures with our plastic molding machines. Wit the help of our user friendly software, operator work pretty easy during plastic injection process.

Request for a quote

TECHNIC MACHINES

Turkey

We design our plastic recycling machine to give best solution for waste plastic recycling process with minimum energy consumption. According to our customer's request, we offer different capacity options. Our plastic recycle machine is used mostly for plastic film and bag recycling process. It can work with raw materials such as PE, PP, PVC, HDPE, LDPE, Polythene, Polystyrene PET and etc. As tp market demand, we design our machine for working even with pretty dirty waste plastic film and bag. Also we offer our customers fully automatic or semi automatic solution. So, we provide for our customers, the plastic recycling machine according to their requirements. Plastic recycling line main units, – Bale Opening Unit – Shredder Unit – Helezons – Washing Systems – Separator Units – Screw Loading Units – Friction Washing Units – Dewatering Machinery – Agglomeration System – Granulating Machinery – Big Bag Filling Unit

Request for a quote

TECHNIC MACHINES

Turkey

Our plastic sheet extruder machine lines have different production capacity range and we provide our sheet extrusion machine lines for different plastic sheet products so that we can match with our customer's requirements. We provide our sheet extrusion line for different raw materials such as pvc, pp, ps / polystyrene, pc / polycarbonate, hdpe / ldpe, pet and for other. Plastic Sheet Extruders by Raw Material - PET Sheet Extruder Machine - PP Sheet Extruder Machine - PE Sheet Production Line - PVC Sheet Extruder Line - PC Sheet Extrusion Machine - ABS Sheet Extruder Machine Plastic Sheet Extruders by Final Shapes - Rigid Sheet Extruder Line - Plastic Board Extrusion Machine - Foam Board Extruder Lines - Hollow Sheet Extrusion Machine - Corrugated Sheet Extruder Machine - Honeycomp Board Extruder Machine Just contact with us for other plastic sheet extruders according to your specific raw materials and shape, we will offer the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our rattan extruder machines have different production capacity range and also capable to produce different rattan sizes, so that we can match different demand. You can produce with our rattan extruders different final product such as furniture and decoration etc. Plastic rattan raw material is mostly PE. PE has the highest stability if you compare with other plastic rattan raw materials alternative. Other most common raw materials for plastic rattan extrusion are PVC and PU. Where you can use plastic rattan ? - Rattan Chair - Rattan Table - Rattan Sofa - Rattan Coffee Table - Rattan Bench Just contact with us for your rattan extrusion machine research, we will provide the optimum solution for your research.

Request for a quote

SHANGHAI DURA INDUSTRIAL CO., LTD.

China

Our factory’s Automatic Tag Eyelets Punching Machine mainly used to punch the eyelets on the tags or labels automatically. Features: 1. Using the frequency converter, touch screen , PLC , sensor electronic control system,easy to operate and control. 2. Different size and material tags can be puched with different size eyelets. 3. Automatic feeding eyelets. 4. The machine size is small and weight is light. 5.Low noise and simple maintenance. Specification: Speed:3000-5000pcs/h Size of tags:40*70mm Height of feeding material:250mm Size of tags:110*133mm Min thickness of tags:157g Max thickness of tags:700g Routine eyelet diameter :4mm eyelet +4.8mm hole size Voltage:3phase 380v Power:750w Machine size:700mm*900mm*1250mm Machine weight:350KGS Quality Control: All the machines will be inspected carefully before delivery.

Request for a quote

ADMET SP. Z O. O.

Poland

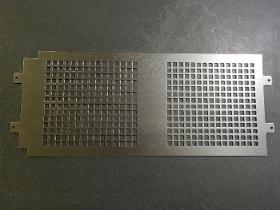

We offer sheet metal punching for all kinds of materials. We work on AMADA machines. Max width: 3000mm Max thickness: 6mm

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

These materials offer numerous advantages when working with them, which is why they are increasingly being used in comparison to other alternatives such as metals. Technical applications require parts with very specific features. Research and development thus play an important role in obtaining innovative items.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

New design adopted for punching stainless steel. Inching function as standard. 25mm and 26mm dia. holes are possible with optional parts.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The Professional Line punching machines by EHRT are characterised by their outstanding robustness even under high loads. With the Professional machines a three-shift operation, for example, is not an issue. This machine is fitted with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding in the material and removing the production parts can be further automated. This makes the machines extremely cost-effective. Software solutions from EHRT enable a customised and smooth production flow of punching machines. In addition, the punching machine can be optimally linked with the bending machine so that production can be carried out based on a single production file from a common database.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the customer’s individual requirements via individual components. The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. Through additional options, however, the processes of feeding the material and removing the production parts can be further automated. This makes the punching machines extremly cost-effective. EHRT's software solutions enable a customised and smooth production flow of punching machines. In addition, the punching machines can be optimally linked with the bending machines so that production can be carried out based on a single production file from a common database.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The Professional Line punching machines by EHRT are characterised by their outstanding robustness even under high loads. Running a three-shift operation, for example, is not an issue. The Punching Machine Professional Series is fitted with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding in the material and removing the production parts can be further automated. This makes the machines extremely cost-effective.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FOXLASER

Bulgaria

The punching is a preferred technology in cutting-out of galvanized metal sheets. In FoxLaser we have 4 pc. punching machines that enable us to process without repositioning sheet material with dimensions 3000/1500/3mm. The main advantage compared to laser technology is the possibility of cutting and forming of the sheet material. The combination usage of punching and laser cutting allows us to make numerous identical holes (grid) or just forming in a laser cut parts. The biggest advantage in FoxLaser punching are a tripple tooling we have that allows us to produce same time same part in all machines. For achieving maximum performance we work with wide range of functionalities by the well proved softwares SigmaNEST and Metalix CNCKad, in combination with the customized software of the company AMADA.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

HTMACH Turret Punch Press Machine is capable of working large sheet metals with fast axes speed and stroke frequency. It is used high level mechanic and electronic automation equipments in its construction. Machine keeps its compact structure with all its specialties and equipment. All of the components on the machine are world wide known brand names. Capacity is 1225mmX30ton

BOGRAMA AG

Switzerland

Mobile transfer unit for inline operation with the BSR 550 Servo rotary die-cutter. For the perfect gripping of die cut products. Fitted with clocked air nozzles for the separation of inner cuts.

Request for a quote

BOGRAMA AG

Switzerland

"The compact and attractively priced BSR 550 basic is structured as an offline solution. It is designed specifically for users who want to produce small and medium runs economically and efficiently as well as for those for which the flexible connection options and technical features of the BSR 550 Servo have no priority. Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. To exchange the flexible dies the entire breakout and deliver unit is disconnected from the die-cutting area. Thus an optimal accessibility is guaranteed. After die-cutting the inner cuts are separated and the section grids deflected.

Request for a quote

BOGRAMA AG

Switzerland

This machine configuration is the most flexible variant. It can not only be combined with downstream but also with upstream equipment such as cross cutters, digital printing machines and folding machines. Products are fed individually to the punching area via register table and rotary punched by using a flexible die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h.

Request for a quote

BOGRAMA AG

Switzerland

In this configuration variant, products are fed to the punching area individually from the pallet feeder and rotary punched by using a flexible die. The maximum stack height of the feeder is 100 cm. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed.

Request for a quote

BOGRAMA AG

Switzerland

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h

Request for a quote

MVD MACHINERY

Turkey

MVD Turret Punch presses are produced as a closed type rigid steel constructions in to a robust structure to provide minimum deflection during operation. Complete solutions with effective costs.

Request for a quote

PRECITOOLS SRLS

Italy

We present semi-automatic grinding machine F-Grinder to sharp punching tools (punches and dies) for various models and systems of punching presses: Trumpf Trumatic, Trumpf Trupunch, Boschert, Haco, Pullmax , Amada, Finn-Power, Prima-Power, Durma, Schiavi, LVD, Strippit, Danobat, Yawei, Nisshinbo, Euromac, Baykal, FIM, Murata Muratec, Rainer, MVD, Tailift, SimasV, Yangli, Peliant, SNK, Pullmax, Hesse-Maschinen, Ermaksan, Dener, ITEK, SMD etc. Grinding of punches and dies with height up to 230 mm, diameter of 180 mm. Control panel SIEMENS TOUCH. Machine is with coolant, closed grinding area, 3-jaw universal chuck, no any additional adapters are needed. Table tilt to make the angle grinding. Please contact by E-mail for the detailed offer. This is the advertisement, not the official offer. All the mentioned brands and trademarks pointed just for the information and are the property of their respective owners.

Request for a quoteResults for

Punching machines- plastic - Import exportNumber of results

27 ProductsCountries

Category

- Punching machine tools (12)

- Industrial cutting machine tools (4)

- Punching machines, plastic (4)

- Extrusion, plastics - machinery (2)

- Garment industry - machines and equipment (1)

- Grinding - machine tools (1)

- Injection, plastics - machinery (1)

- Milling and turning of rubber and plastic (1)

- Plastic material processing (1)

- Plastics - machines and material for industry (1)