- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sealing and wrapping - machinery and equipment

Results for

Sealing and wrapping - machinery and equipment - Import export

ÖZKA MACHINE AUTOMATION

Turkey

Full Automatic Rewinding And Changing Unit Counter And Quantity Reporting Film Finish Sensor Coil Finish Sensor Cutting With Hot Wire Omron Plc Control System Omron 7" Touch Panel Omron Main Driver Mindman Pneomatic System

Request for a quote

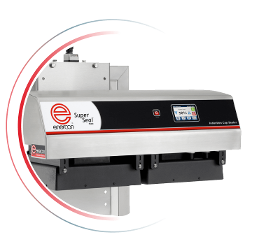

ENERCON INDUSTRIES LTD

United Kingdom

Enercon has two coil design types, each with several variations, to ensure the perfect coil is available for the size and type of your container and cap for your application to deliver perfect, consistent seals. Tunnel coils facilitate higher throughputs than the more traditional flat coils. The Deep Tunnel Coil is used for conical, spouted and other shaped caps. The All-in-One Coil is a variation of the Flat Coil. It is available with the Super Seal™ range and Super Seal™ Touch. This flat sealing head can be pivoted to accommodate various applications. Capable of sealing containers with cap diameters ranging from 20mm to 140mm, it is ideal for packagers who seal a variety of containers and offer the highest degree of sealing versatility. Packagers often don’t realise that the efficiency of the sealing operation depends on the design of the sealing head.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

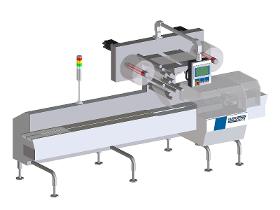

Many of the issues causing poor seals happen upstream, in the filling or capping area: a seal cannot be achieved with a missing cap or a cap with a missing foil. The capper can also cause stalled bottles under the induction coil where caps are loose or partially fitted or the cap is incorrectly fitted or too high. Issues downstream from the sealer can cause containers to back- up under the sealing head. Enercon produces a range of sensors to help ensure that the sealing process is running faultlessly, producing consistent, reliable seals on every container. • Stalled Bottle and Backlog Detector • Missing Foil Sensor • High Cap Detector • Stack light assembly • Variable Speed Conveyor Systems • Spare Parts Kit • IQ/OQ Kit

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

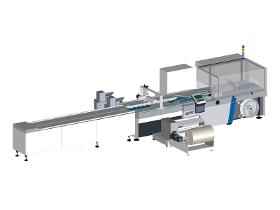

The benefits of induction technology in a capless sealing process. Successful sealing on both capless and non-screw-cap containers such as snap on caps is now possible with a pressure Sealer incorporating an Enercon Super Seal™ unit. Typically, pressure belt sealing is used to replace conduction sealing or to reduce the dwell-time needed in conduction sealing. Seals are either placed onto the capless containers or reside in the cap as inserted by the cap manufacturer. The capped container is then guided through the induction heating tunnel, where downward pressure is applied to the clip-on cap or foil by a non-metallic recirculating belt. This unique design automatically takes account of component variations and tolerances, such as bottle height variation, product overfill, line speed variation and bottle centres. Incorporates an Enercon Super Seal™ unit • Cap sizes up to 110mm diameter • Conveyor Speed up to 40 metres / minute

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

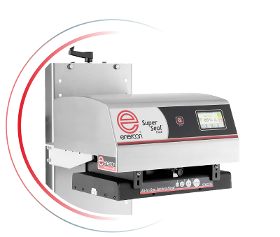

The Super Seal™ Auto Junior semi-automatic induction cap sealer offers the benefits of high-quality induction sealing to start-up operations, product validation and short production runs. The Enercon hand-held cap sealers deliver reliable, repeatable induction sealing and feature quality aids such as batch counters and no-foil indicators, which are often only found on inline production machines. The quality, reliability, and safety and support of Super Seal™ Auto Junior is the same as our high-volume inline production machines. Our hand-held machines are virtually maintenance free and seal continuously time after time for many years without fault. • Fully adjustable table-top stand • Diameter 20-63 mm • Digital timer • Missing foil indicator • 500W output • Dimensions 17.8mm W x 30.0mm D x 38.0 cm H

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Sleever wrappers operate with an upper and a lower film and are ideal in quickly providing heavy, large products with a safe protective packaging and/or transit packaging. Our robust sleeve wrappers are perfectly accessible from both sides. The lateral film unwinding units enable a quick and user-friendly roll change. As the product's sides remain open, film use is minimised. As an option, the BP 800 features an ultrasonic height detection system, enabling Hugo Beck's flexible banderoling machines to wrap products with a width of up to 800 mm and a height of up to 400 mm in film. In addition to our standard sleeve wrappers, special banderoling machines for special applications such as the stretch-banding of carton blanks are also part of the Hugo Beck portfolio.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Items that have initially been bagged using a machine from Hugo Beck often need to be shrunk so as to ensure a tight-fitting film and the perfect packaging finish to meet the highest standards. Adapted for each packaging system, we supply the appropriate shrink tunnel in all sizes and performance ranges for the production of high-quality shrink packaging. As such, we manufacture shrink tunnels in a number of versions, with a variety of rods and chains that operate like a link mesh belt. Textile mesh belts are also possible for very light products. In each case, the length of the shrink tunnel depends on the speed of packaging and on the film material selected. State-of-the-art air ducting and heat recovery ensure efficient energy use, helping us to contribute to both protection of the environment and reducing energy costs. The decision on whether to use a shrink tunnel with circulating air or convection principle is defined depending on the individual product application of the customer.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Our fully automatic flowpack machines are suitable either for high-speed applications or airtight packaging requirements, depending on the version selected. The machines feature either rotating or box motion transversal sealing units, with selection of a longitudinal seam either above or below. Each machine can be combined with a wide range of feed systems, such as finger conveyor chains or infeed belts. With our ability to handle everything from PP or aluminium laminated films through to Tyvek® – anything is possible. PE-coated paper can also be used for flowpack production. Our flowpack machines are also available as hygienically designed versions.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Paper or film? Stay flexible! A single machine can now deliver both film and paper packaging applications. The continuous Form Fill and Seal Machines paper X hybrid are designed for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material. Whether using a chain infeed or infeed conveyor, the machines stand apart through their continuous packaging process – without stop-and-go – maximising efficiencies by ensuring there is no downtime when sealing or glueing. Our paper packaging solutions are available in different versions, depending on how flexible you need to be: - the basic model paper X features paper packaging with overlap on top - the paper X hybrid features paper and film packaging with overlap on top - the paper X hybrid advance features paper and film packaging with overlap on top and side seal

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The continuous Form Fill and Seal machines servo X 800 are the most flexible and powerful of film packaging machines in the large-format segment – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements. They are designed for packaging large-format products with a width of up to 800 mm and a length from 150 mm. Whether chain infeed or infeed conveyor, the machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled. Depending on customer requirements, these packaging machines are equipped with different control systems.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The continuous Form Fill and Seal machines of the servo X series are available in five performance ranges and numerous variants. They cover the broadest possible range of horizontal film packaging applications for various industries – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements for the desired performance or type of packaging. Depending on the machine variant, several packaging styles can be flexibly produced with one machine. Whether chain infeed or infeed conveyor, servo X machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The high-performance and extremely flexible intermittent Form Fill and Seal machine flexo H is particularly suitable for film packaging of wood and similar long parts from 800 mm in length, such as parquet or laminate, mouldings, wood or laminated wood, furniture parts or doors. It takes just five minutes to deal with a pallet of laminate. Similarly, our flexible packaging machines are ideal for similar length products, including skis and snowboards, spirit levels, rolled goods, steel pipes, and many more items.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent Form Fill and Seal machines flexo 500/700 Push are pusher-machines that wrap difficult products with ease, such as glass bottles in bundles or salt and pepper shakers. They collect and group the products in order to subsequently push them into the film. In order to ensure that no products tilt over, our machines maintain physical contact with the articles to be packaged until they are safely in the bag. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions. The packaging styles features a bottom overlap.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

With the paper e-com fit you are optimally equipped to meet the demands of e-commerce packaging in paper. Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging, the paper e-com fit packs goods with a minimum use of paper or film. Both uncoated and coated paper can be used for producing paper bags with two glued or sewn sides plus a top overlap. The shipping bag size is automatically adapted to the dimensions of the product during production. Thus, different product sizes can be packaged in a jumble. Furthermore, the machine offers the possibility of storing two paper rolls of different widths. After the product scan, the packaging machine then decides how wide the paper web must be and can select one of the two paper rolls. This minimizes paper use.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

With the flexo 700 E-Com you are optimally equipped to meet the demands of e-commerce packaging in film. It is Hugo Beck’s most flexible and efficient machine for these applications. Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging, the flexo 700 E-Com packs goods with a minimum use of film, maximising packaging results both with and without shrinking of the film bags. A quick changeover between product batches adjusts the machine o new product sizes or, as an option, the machine can automatically adapt to changes in a product’s length, height or width. Additional options include the ability to add an easy-opening perforation to the bags as well as inserting a double-sided adhesive tape for resealing a bag for returns.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent Form Fill and Seal Machine flexo 700 scores similarly to the basic modell flexo 500 with maximum versatility and flexibility, but is designed for the packaging of large format products with a width of up to 620 mm. Whether shoe boxes, boards, shelves, ladders, ironing tables, large calendars, pots, tissue rolls, insulating mats, etc., you are instantly equipped for any kind of large format application with this machine – daily changing orders, for example. The flexo 700 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent Form Fill and Seal Machine flexo 500 scores with maximum versatility and flexibility even in its basic configuration. Whether frozen pizzas, biscuit boxes, fruit and vegetables, books, skis, laminates or various household goods, etc., you are instantly equipped for any kind of application with this machine – daily changing orders, for example. The flexo 500 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENERCON INDUSTRIES LTD

United Kingdom

Available in three models Super Seal™ 300 Super Seal™ 400 Super Seal™ 600 We have built on the proven design of the Super Seal™ range of induction cap sealers, to bring new features to give more value to packagers. The new Super Seal™ compact induction cap sealers are available in three power levels. There are a variety of sealing heads available to optimise sealing performance for your specific applications. •New display simplifies setup, operation & troubleshooting •Local/Remote modes for start/stop & power level •Seals a variety of caps ranging from 20 – 150m •System settings in a single level menu •High efficiency plug-in induction sealing coils to maximise performance and minimise energy costs •Compact and air-cooled •Power supply electronics are housed in an IP55 enclosure •Fully compliant with all UK and European regulations •Fully adjustable stainless-steel stand for different container heights

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

This single coil induction cap sealer offers users increased productivity, an easier set-up and more control. The easy-to-use touch screen is available in multiple languages. The Super Seal™ Touch is our most powerful compact single-coil machine and is designed for production lines running at up to 40 metres per minute. The air-cooled power pack is separate from the induction sealing coil. • Pre-programmed and fully integrated touch screen control for inspection and rejection • Remote start/stop and remote power control (auto start function available) • Password protection with operator lockout • High and low level set power alarm • Recipe management • Internal monitoring of all critical operating data • Diagnostic system information • Internal USB data port – Network connectivity available • Stainless steel IP55 enclosure • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Junior manual induction cap sealer offers the benefits of high-quality induction sealing to start-up operations, product validation and short production runs. The Enercon hand-held cap sealers deliver reliable, repeatable induction sealing and feature quality aids such as batch counters and no-foil indicators, which are often only found on inline production machines. Our unique coil design facilitates the sealing of a wide range of caps including flat, sauce dispensing and conical caps, at diameters from 15 – 150mm. Other hand-held devices will only seal flat caps. The quality, reliability, and safety and support of the Super Seal™ Junior is the same as our high-volume inline production machines. Our hand-held machines are virtually maintenance free and seal continuously time after time for many years without fault. • Handheld and portable • Cap size 15-150 mm • Batch and foil counter • Digital timer • Missing foil indicator • 1KW output

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Max is the fastest inline sealer on the market, with a dual coil it’s designed for high-speed packaging lines running at up to 100 metres per minute. This dual coil air-cooled induction cap sealer offers increased power and a multi-language touch screen for a simpler operation. It delivers reliable sealing with a diverse operating window that compensates for cap, liner and container tolerance variations. • Multiple language selection • Easy to use touch screen • Supervisory password protection with operator lockout • Recipe management • Internal monitoring of all critical operating data • Container, cap and foil counters available • Local and remote start/stop and power control • Stainless steel IP55 enclosure • Remote network control and monitoring via RS485 or Ethernet • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm • Fully compliant with all CE regulations

Request for a quote

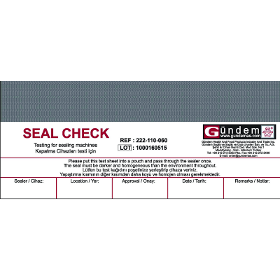

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• Suitable for sealers with Builtin DotMatrix Printer. • 1 Million hits guaranteed. • It is suitable for 10GM, 20GM, 50GM and 60GM model devices.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• These tests are designed as two models and should be selected according to the type of pouch you use. • These tests should be performed daily before each use, before the sealer is used. These tests are defined in ENISO 116072 and DIN 58953. • Take one SealCheck sheet out of its package and place it in a pouch with a width of at least 20 cm. Give it to your device together with the pouch. Successful or, if any, incorrectly sealed areas will be clearly seen in the pouch that comes out of the process. For the maintenance of your device in case of malfunction, contact the place where you bought your device and have the parts replaced to return your device to factory settings. • A successful test result shows that your device has been sealed in accordance with EN ISO 116072 standard. The test result can be documented on a daily basis and serves as evidence in audits.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• When the desired number of Cut and Seal operations are completed, it serves to define the cut pouches. • "Manufacturer Name/Logo", Number of Pouches, Date information is written on this selfadhesive label as human readable and barcode. In this way, stock counting is also easy. • Used to get Validation Report on some models • This Thermal label roll is suitable for Thermal Printers integrated into 40GM, 45GM and 50GM model devices. • Inscriptions may disappear when in contact with heat. Therefore, it is recommended to use External Thermal Printer (A130) and Labels.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• When the desired number of Cut and Seal operations are completed, it serves to define the cut pouches. • "Manufacturer Name/Logo", Number of Pouches, Date information is written on it as human readable and barcode. In this way, stock counting is also easy. • Used to get Validation Report on some models • This Thermal paper roll is suitable for Thermal Printers integrated into 40GM, 45GM and 50GM model devices. • Inscriptions may disappear when in contact with heat. Therefore, it is recommended to use External Thermal Printer (A130) and Labels.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• Provides the identification of barcodes on packaged products • Provides the transfer of predefined codes to sealers in the institution, • Provides device automation in some models (Using devices with QR code reader instead of touch screen), • It allows to transfer the Product/Set codes up to 9999 in the device memory to the sealers, • You can give work orders to the device by reading the Product/Set codes in an A4 page/List, • This reader is suitable for 20GM, 40GM, 45GM, 46GM, 50GM and 60GM model devices.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• In Full Automatic Rotary Sealers and Pouch Makers, when the target number of pouches is reached, the total number of pouches/packages, their contents, Institution Name and Logo can be read and written on the label as Barcode / QR Code. • Labels obtained from the thermal printer also serve to seal the box in which the produced bag/packs are placed. • These labels can also be printed individually for each Pouch/Pack produced in the Sealing Device. • The print on the labels is not erased in hot environments (especially in an autoclave). • These labels are available in versions with Steam, Ethylene Oxide, H2O2 (Plasma) indicator and without indicator. • This printer is suitable for 20GM, 40GM, 46GM and 60GM model devices

Request for a quote

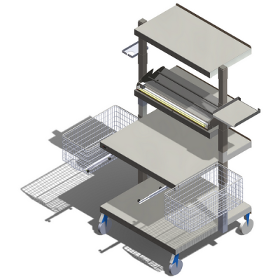

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This mobile workstation is produced for packaging sterilized products, examining surgical instruments, etc. The Workstation includes a mobile base element, a large worktable with lower and upper shelves, autoclavable 1STU baskets, Barcode reader and thermal printer racks. • 1 Pcs Top Stocking Rack Group (#223300017SA4), • 1 Pcs Side Rack Left Group Mini (#223300015SA5.2), • 1 Pcs Side Rack Right Group (#223300015SA5.1), • 1 Pcs Working Table Group (#223300015SA2), • 1 Pcs.. Telescopic shelf system (#223300015SA1.2.1), • 1 Unit Lower Table Group (#223300015SA1), • 3 Autoclave Baskets (#222110050) • Size & Weight 1200 x 808 x 1500mm 85 Kg (excluding device, baskets and other accessories)

Request for a quote

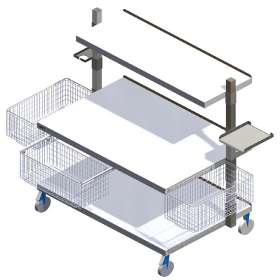

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This mobile workstation is produced for packaging sterilized products, examining surgical instruments, etc. The Workstation includes a mobile base element, a large worktable with lower and upper shelves, autoclavable 1STU baskets, Barcode reader and thermal printer racks. • 2 Pcs. Upper Stocking Rack Grb (223300017SA4), • 1 Pc. Side Shelf Left Grb Mini (223300015SA5.2), • 1 Pc. Side Shelf Right Grb (223300015SA5.1), • 1 Pc. Manual Roll Cutting Apparatus (A065 222110021), • 1 Pc. Working Table Grb (223300015SA2), • 1 Pc. Telescopic rail system, (223300015SA1.2.1), • 2 Pc. autoclave basket (A072222110050), • 1 Pc. Lower table Grb (223300015SA1). • 1 PC. Allen wrench. • Dimension (Width x Deep x Height) and Weight 800 x 808 x 1700mm 80Kg. (excluding device, baskets and other accessories).

Request for a quoteResults for

Sealing and wrapping - machinery and equipment - Import exportNumber of results

70 ProductsCompany type