- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stud welding equipment

Results for

Stud welding equipment - Import export

KÖSTER & CO. GMBH

Germany

Weldable stud range 3–10 mm Ideal for KÖCO Stud Welding Equipment KST Ergonomic body

Request for a quote

KÖSTER & CO. GMBH

Germany

Weldable stud range 3–10 mm Ideal for KÖCO Stud Welding Equipment KST Ergonomic body

Request for a quote

KÖSTER & CO. GMBH

Germany

Stud welding equipment with capacitor discharge Suitable for welding steel, stainless steel, aluminium and brass Weldable stud range 3-10 mm stud diameter Continuously adjustable charging voltage Digital display of charging voltage Weight only 9,9 kg Steel housing, powder-coated

Request for a quote

KÖSTER & CO. GMBH

Germany

Stud welding equipment with capacitor discharge Suitable for welding steel, stainless steel, aluminium and brass Weldable stud range 3-8 mm stud diameter Continuously adjustable charging voltage Digital display of charging voltage Weight only 8,9 kg Steel housing, powder-coated

Request for a quote

PERGEL METAL

Turkey

Stud Welding is the process of sticking to the surface as a result of applying spring force by applying a quick process to the area to be welded, ensuring the melting of the surface by pressing. There is no need for any preliminary preparation. In other words, no operation such as drilling is performed. The only thing that is wanted is that the surface is clean. It creates a strong connection. There will be no traces of welding. The production cost becomes lower and it is also advantageous in terms of time. It will be enough to conduct a study for one reason or another. For two hundred, there is no need to perform an operation. It can be used for a variety of metals. Materials such as iron, steel, aluminum and stainless are the most preferred stud welding materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROTEC TRADING GMBH

Austria

English | Deutsch | Español | Português | Français | Italiano | Русский Visit our website for information in your language. Welding-Milk PROTEC CE16M Light biological separation agent to prevent adhesion of weld spatter on components. Particularly suitable for thin sheet metal panels, optimised to produce minimum emissions and leave minimum residue. Protects any type of metal surfaces, except aluminium. No silicone, non-flammable, and biodegradable.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Fit-Up systems shortens the big diametric and heavy pieces’ montage period in cylindrical piece fabrication and reduces the need of crane and operator. Fit-Up systems basically consist of 2 main rotator teams. With the fixed rotator system, pieces’ heights towards each other are adjusted while rotator amount increases according to piece tonnage. Other rotator systems are mobile and as it appends to the piece it moves forward and basically make the movement of the piece’s rotating movement. With the help of column-bom which is the source of montaged pieces on Fit-up systems, it can be finished quickly while saving man-hour. In Fit-up system basically; besides the fixed rotator set that adjusts montage and heights it contains 2 motorized and 1 wanderer rotator systems.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Rotators are resistant to severe working conditions and are designed to rotate work pieces weighing 5 to 150 tons. It enables the cylindrical parts weld sensitively by rotating clockwise or anticlockwise. In line with customer’s demanded diameter and tonnages, its production can be made auto regulative or conventionally. Features -Through polyurethane coated wheels rotation quakes and uploading hitting are absorbed during welding. -In the applications requiring high temperature and major load, featured steel wheels can be used as well. -Wheels possess self-adjusting feature for small or big diameters. This adjustment can be made with ball screw or by hand optionally. -For the manual usage, digital control or analog entries can be integrated to Column Bom systems. -Sensitive rotation with low gaped reducer -Synchronised working feature -Power transmission with flat gears

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

Your #1 source for welding automation and positioning equipment hire. We will not be beaten on price. Key Plant will undercut any genuine quote. We have comprehensive stocks of high quality and reliable weld automation, handling and positioning rental equipment. From welding rotators, tank turning rolls and welding manipulators to pay by the hour, plug and weld robotic welding cells – find your ideal rental solution today. A major advantage we have over our competitors is that, as the manufacturer we have the ability to keep an extensive level of available ‘rent-ready’ stock. A rental department built over 65 years. Short or Long Term Project? Perhaps you have equipment that requires maintenance or a refurbishment, but cannot afford production downtime? We offer affordable rental solutions to help you keep your production at an optimum level. Rental also enables you to evaluate your needs before purchasing.

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

COMPANY TOR

Russia

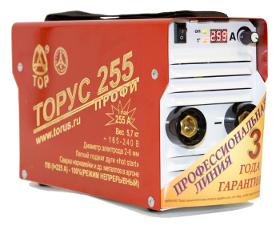

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quoteResults for

Stud welding equipment - Import exportNumber of results

12 ProductsCompany type