- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam boilers for industrial use

Results for

Steam boilers for industrial use - Import export

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Steam is a pressure vessel manufactured to store excess steam or waste vapors out of the operation of aquaria and to be used again when necessary. They are mainly used in gas concrete installations especially for the purpose of recovering the waste steam from the process. There are water and vapor phase zones in the steam chamber. The volume is 4/3 water phase. Steam The steam is stored in the battery in the hot water phase by injecting the steam into the water by means of the diffusers located below the water level and dissolving it in the water. When the steam is needed, the pressure of the hot water is lowered and the steam produced by the resulting phase change is transferred to the process to be used again. Using a steam bath; Up to 25% energy saving is achieved. They can both discharge steam and discharge at the same time. Suspended solid materials which are dragged together with the steam collapse under the liquid and the bluff is removed from the environment and the steam is

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Steam boilers with water pipes are boilers in which the water circulates and evaporates in the pipe. This high-capacity, high-capacity, high-capacity steam boiler. The combustion chamber is surrounded by a pipe-pipe-pipe joint. As a fuel in water pipe steam boilers; They use solid fuel, liquid fuel and gas fuel. n terms of safety, the water is more secure due to circulation in the pipes. Because of their lower water volumes, they are boilers that enter the regime more quickly.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Bundles are used for generating superheated, saturated steam and hot water to meet the requirment of process by utilising waste heat in power plants. We manufacture bundles according to ASME and EN standard with high frequency welded fintubes which is produced by Eralp. *We are manufacturing Solid and Serrated Type. *We can weld fin material thickness between 0,8 mm - 2 mm for high frequency welded spiral finning tubes. *It is possible to weld fin thickness less than 0,8 mm but it is not recommended. *Pitch distance is determined according to pipe diameter and thermodynamic calculation. We are able to manufacture fintubes pitch in the range of 3,5 - 20 mm.

Request for a quote

NOVELTY STEEL

Turkey

The construction of a boiler involves a diverse range of materials and components, broadly categorized into boiler steels, structural steels, and bought-outs (BOs). These materials are chosen based on factors like weldability, strength, and compliance with safety standards to ensure integrity and reliability.

Request for a quote

NOVELTY STEEL

Turkey

The construction of a boiler involves a diverse range of materials and components, broadly categorized into boiler steels, structural steels, and bought-outs (BOs). These materials are chosen based on factors like weldability, strength, and compliance with safety standards to ensure integrity and reliability.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With impressively low emissions and its ability to be converted for biofuels or hydrogen, the UL-S is designed to be future-proof. — Very high efficiency for low running costs and emissions — Complete system with customer-specific equipment and future-proof technology — Extremely well proven design “Made in Germany”, highly durable and easy to maintain — Consistent steam quality for reliable supply — Custom designs available for heat recovery boilers, hybrid or superheated steam — Smart boiler control and seamless system integration with digital assistants — Fuel: Oil, gas, multi-fuel firing, Biogas, bio-oil, hydrogen, special fuels

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The steam boiler CSBs low emissions already comply with future requirements of the MCP Directive (EU) 2015/2193. — Large output range from 300 to 23,600 kg/h for pressures ranging between 0.5 and 16 bar — High efficiency thanks to the integrated economiser and helical heat exchanger pipes — Versatile design for use with different fuel types and as a multi-fuel firing unit (oil, natural gas, bio gas, up to 20 % hydrogen) — Compliant with even strict emission levels when used in combination with our burners and controls — Telescopic reversing chamber makes cleaning, maintenance and inspection simple — Easy to operate with CSC boiler control (up to 4,000 kg/h) and boiler control

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the convenient operation of steam boilers up to 4,000 kg/h of steam — Appealing price-performance ratio for steam boilers up to 4,000 kg/h of steam — Colour touch display for easy operation and clear visualisation of operating status — Flexible installation and small space requirement: installed on the boiler at the factory or loose control cabinet for wall mounting — Power electronics for fuel supply, feed water pump, blow-down and desalting — Optional: fully automated and conductivity-controlled blow-down and desalting

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Environmentally friendly generation of steam from available waste heat — The perfect addition to energy concepts involving combined heat and power generation — High efficiency through efficient tubular heat exchanger and thermal insulation — Additional efficiency gain thanks to optional integrated economiser — Matched, modular system for easy planning and fast installation

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Three-pass boiler for a small to medium steam demand of 200 to 2,000 kg/h at up to 16 bar — Lower space requirement for easy installation — High level of efficiency due to the integrated economizer — Versatile design for use with different fuel types and as a multi-fuel firing unit (oil, gas, biogas, bio-oil, hydrogen, special fuels) — Intuitive touchscreen operation and PLC control — Easy wiring on site thanks to plug-in connections

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Two independent firing units and flue gas paths offer very high flexibility in the ZFR thanks to a doubled modulation range. — Very high efficiency across the entire power range — Reliable solution for highly fluctuating steam demand — Project-specific equipment and optional components, for example superheated steam generation — Future-proof with options for low-NOx and CO2-neutral operation — Smart boiler control and seamless system integration — Stable supply and durable design Made in Germany — Fuel: Oil, gas, multi-fuel firing, Biogas, bio-oil, hydrogen, special fuels

Request for a quote

METMANN

Spain

Hot air fan heaters with water coil (20 to 106 kW) - ATR The hot air heaters with hot water coil are ideal for heating all types of commercial, industrial or agricultural premises where a flow of hot air is required to heat different areas of the premises to be heated. The hot water must be produced by a diesel, gas or biomass boiler. The hot water, by means of a circulation pump, passes through the interior of the heating coil of the air heater and the heat transfer is carried out by the air fan of the air heater. The fan can be axial or centrifugal, the axial type is used for direct dissolution and the centrifugal fan allows a network of ducts to be applied in addition to having a greater reach.

Request for a quote

CFB BOILERS LTD

United Kingdom

10 - 130 HP STEAM BOILERS

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Thanks to large contact surface of water with smoke pipes, high operational safety and longer boiler life are guaranteed. The small water volume provides a better inside circulation and safe heat transfer with faster steam generation time. Increased strength and flexibility with corrugated furnace that is manufacturing by Eralp in 900°C degrees. In 3-pass Shell boiler design, the heat load of furnace is less than 1,2 MW/m. The result of this design is an ideal combustion with less NOx emissions, thus it causes lower fuel consumption. Further gains in efficiency can be obtained by using economizer for feeding water by preheating and air-heater for combustion air heating. The energy of flue gas can be recovered and the efficiency of boiler system is increased 5-8%. According to pressure of boiler, efficency increase up to %91. Eralp manufactured the highest efficent boiler (totally efficiency=%98,4) with two economisers which efficency tested and approved by Notify Body.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

They are high-quality steam generating equipment used in all industrial plants to obtain steam required for processing. Steam boilers with flame smoke pipes can be produced as flat ashtrays and hot ashtrays. Solid, Liquid and Gas fuels are used as fuel type. Eralp Makina Kazan In 2005, it is proud to be the most productive employee of Turkey with double economy working with natural gas (total system efficiency = 98,4%). Yield tests of our product produced by Yildiz Technical University and ISKAV Foundation.

Request for a quote

EKOTEK ISI TEKNOLOJILERI SAN.TIC. LTD. ŞTI

Turkey

LIQUID AND GAS FUEL, SCOTCH TYPE THREE-PASS, HIGH PRESSURE STEAM BOILERS 175 kg / h - 28.000 kg / h steam production capacity 3 - 16 bar operating pressure •Products can burn fuels such as natural gas, lpg, lng, diesel, fuel oil, biogas. You can choose the burner brand according to your request. EKOTEK, Trademark registered and controlled and audited by ISO 9001: 2015 quality management system.

Request for a quote

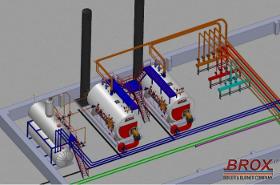

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

18-20% fuel saving, efficient steam generator, generating steam in 3 to 5 mins. Due to it is modular design, number of generator in system can be specified as per customer steam demand and the generators starts and stops according to steam consumption.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

1 ton/h to 18 ton/h Industrial Fire tube Steam Boiler, generating superheated or saturated steam, fired Gas, Liquid and/or Solid fuels, turnkey project flexible solutions as per customer demand.

Request for a quote

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

Water tube Steam Boiler, generating superheated or saturated steam, fired Gas, Liquid and Solid fuels, turnkey project solutions.

Request for a quote

ATTSU TERMICA S.L.

Spain

With steam production from 0.5 t/h (349 kW) up to 20 t/h (13.000 kW). The CSPM boiler is a three-pass horizontal fire-tube steam generator, with a furnace designed for biomass.

Request for a quote

KRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ECOPAR 0.7 BAR LINE ЕСОPAR steam boilers are designed for generating lowpressure steam for purposes of production and heating supply of residential, public, and manufacturing buildings. ЕСОPAR steam boilers are seriesproduced in the range of nominal steamgenerating capacity from 0,1 to 10 tons per hour with a rated pressure of 0,7 bar (0,07 MPa) and designed for generating saturated steam with a temperature up to 120 °С according to the saturation point at the operating pressure. ЕСОPAR steam boilers are firetube with a passthrough furnace, threecourse version, with installed swirlers for enhanced performance and decreased combustion intensity. The boiler design makes it possible to maintain and clean the boiler flue and firetubes by opening the rotable parts of the front and the tailpiece of a boiler.

Request for a quote

KRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ECOPAR 0.7 BAR LINE ЕСОPAR steam boilers are designed for generating lowpressure steam for purposes of production and heating supply of residential, public, and manufacturing buildings. ЕСОPAR steam boilers are seriesproduced in the range of nominal steamgenerating capacity from 0,1 to 10 tons per hour with a rated pressure of 0,7 bar (0,07 MPa) and designed for generating saturated steam with a temperature up to 120 °С according to the saturation point at the operating pressure. ЕСОPAR steam boilers are firetube with a passthrough furnace, threecourse version, with installed swirlers for enhanced performance and decreased combustion intensity. The boiler design makes it possible to maintain and clean the boiler flue and firetubes by opening the rotable parts of the front and the tailpiece of a boiler.

Request for a quoteKRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ЕСОPAR 10 bar steam boilers are designed for generating saturated steam with a temperature up to 185 °С. Their steamgenerating capacity varies from 0,1 to 10 tons per hour at a steam pressure to 1,0 MPa. The boilers can be used to obtain steam for technological purposes of enterprises, as well as generation of heat energy for the heating systems of residential, public, and manufacturing buildings. The steam boiler with flame inversion consists of a cylindrical furnace with wetted bottom, where flame forms and combustion products are being inverted. Flue gases enter the tube pack of the front tube plate and are sent toward the back tube plate, which they leave through the flue connection. The boiler design ensures low heating and surface loads in the combustion chamber. The boiler body consists of shell, furnace, boiler bottom and flat tube plates made of highquality steel.

Request for a quoteKRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ЕСОPAR 10 bar steam boilers are designed for generating saturated steam with a temperature up to 185 °С. Their steamgenerating capacity varies from 0,1 to 10 tons per hour at a steam pressure to 1,0 MPa. The boilers can be used to obtain steam for technological purposes of enterprises, as well as generation of heat energy for the heating systems of residential, public, and manufacturing buildings. The steam boiler with flame inversion consists of a cylindrical furnace with wetted bottom, where flame forms and combustion products are being inverted. Flue gases enter the tube pack of the front tube plate and are sent toward the back tube plate, which they leave through the flue connection. The boiler design ensures low heating and surface loads in the combustion chamber. The boiler body consists of shell, furnace, boiler bottom and flat tube plates made of highquality steel.

Request for a quoteKRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ЕСОPAR 10 bar steam boilers are designed for generating saturated steam with a temperature up to 185 °С. Their steamgenerating capacity varies from 0,1 to 10 tons per hour at a steam pressure to 1,0 MPa. The boilers can be used to obtain steam for technological purposes of enterprises, as well as generation of heat energy for the heating systems of residential, public, and manufacturing buildings. The steam boiler with flame inversion consists of a cylindrical furnace with wetted bottom, where flame forms and combustion products are being inverted. Flue gases enter the tube pack of the front tube plate and are sent toward the back tube plate, which they leave through the flue connection. The boiler design ensures low heating and surface loads in the combustion chamber. The boiler body consists of shell, furnace, boiler bottom and flat tube plates made of highquality steel.

Request for a quoteKRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ЕСОPAR 10 bar steam boilers are designed for generating saturated steam with a temperature up to 185 °С. Their steamgenerating capacity varies from 0,1 to 10 tons per hour at a steam pressure to 1,0 MPa. The boilers can be used to obtain steam for technological purposes of enterprises, as well as generation of heat energy for the heating systems of residential, public, and manufacturing buildings. The steam boiler with flame inversion consists of a cylindrical furnace with wetted bottom, where flame forms and combustion products are being inverted. Flue gases enter the tube pack of the front tube plate and are sent toward the back tube plate, which they leave through the flue connection. The boiler design ensures low heating and surface loads in the combustion chamber. The boiler body consists of shell, furnace, boiler bottom and flat tube plates made of highquality steel.

Request for a quoteKRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ЕСОPAR 10 bar steam boilers are designed for generating saturated steam with a temperature up to 185 °С. Their steamgenerating capacity varies from 0,1 to 10 tons per hour at a steam pressure to 1,0 MPa. The boilers can be used to obtain steam for technological purposes of enterprises, as well as generation of heat energy for the heating systems of residential, public, and manufacturing buildings. The steam boiler with flame inversion consists of a cylindrical furnace with wetted bottom, where flame forms and combustion products are being inverted. Flue gases enter the tube pack of the front tube plate and are sent toward the back tube plate, which they leave through the flue connection. The boiler design ensures low heating and surface loads in the combustion chamber. The boiler body consists of shell, furnace, boiler bottom and flat tube plates made of highquality steel.

Request for a quoteKRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ЕСОPAR 10 bar steam boilers are designed for generating saturated steam with a temperature up to 185 °С. Their steamgenerating capacity varies from 0,1 to 10 tons per hour at a steam pressure to 1,0 MPa. The boilers can be used to obtain steam for technological purposes of enterprises, as well as generation of heat energy for the heating systems of residential, public, and manufacturing buildings. The steam boiler with flame inversion consists of a cylindrical furnace with wetted bottom, where flame forms and combustion products are being inverted. Flue gases enter the tube pack of the front tube plate and are sent toward the back tube plate, which they leave through the flue connection. The boiler design ensures low heating and surface loads in the combustion chamber. The boiler body consists of shell, furnace, boiler bottom and flat tube plates made of highquality steel.

Request for a quoteKRASNODAR PLANT OF BOILER AND POWER EQUIPMENT (KZKEO)

Russia

ЕСОPAR 10 bar steam boilers are designed for generating saturated steam with a temperature up to 185 °С. Their steamgenerating capacity varies from 0,1 to 10 tons per hour at a steam pressure to 1,0 MPa. The boilers can be used to obtain steam for technological purposes of enterprises, as well as generation of heat energy for the heating systems of residential, public, and manufacturing buildings. The steam boiler with flame inversion consists of a cylindrical furnace with wetted bottom, where flame forms and combustion products are being inverted. Flue gases enter the tube pack of the front tube plate and are sent toward the back tube plate, which they leave through the flue connection. The boiler design ensures low heating and surface loads in the combustion chamber. The boiler body consists of shell, furnace, boiler bottom and flat tube plates made of highquality steel.

Request for a quoteResults for

Steam boilers for industrial use - Import exportNumber of results

55 ProductsCompany type