- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brick-making - machinery and equipment

Results for

Brick-making - machinery and equipment - Import export

THOMSON MACHINERY BV

Netherlands

Brick making machines available

Request for a quote

TITAN MACHINERY

United Kingdom

The Titan 900S Sand-lime brick machine is a revolutionary piece of equipment in the field of brick production. With its state-of-the-art technology and precision engineering, this machine is designed to manufacture sand-lime bricks with unmatched quality and efficiency. Whether you're in the construction industry or involved in brick manufacturing, the Titan 900S will significantly enhance your production processes. It's the ultimate solution for producing durable and environmentally friendly sand-lime bricks. Invest in the Titan 900S and elevate your brick production to new heights.

Request for a quote

TITAN MACHINERY

United Kingdom

A brick and block making machine is a versatile piece of equipment capable of producing high-quality bricks, blocks, and tiles. These machines are essential in the construction industry, providing the means to create durable and reliable building materials. Whether it's for residential, commercial, or industrial projects, these machines play a crucial role in meeting the demand for robust construction materials. They offer precision in molding, ensuring uniformity in size and shape, which is vital for structural integrity. With advancements in technology, modern brick and block making machines are designed for efficiency, allowing for faster production without compromising on quality. They can handle various raw materials, including concrete, clay, and fly ash, making them adaptable to different construction needs. In addition to standard bricks and blocks, these machines can produce interlocking blocks, paving tiles, and more, expanding their utility in the construction world.

Request for a quote

TITAN MACHINERY

United Kingdom

A mobile brick plant, also known as a mobile brick making machine or portable brick manufacturing unit, is a versatile piece of equipment designed for on-site brick production. Unlike traditional brick manufacturing facilities that are fixed in one location, a mobile brick plant can be transported to different construction sites, allowing bricks to be produced right at the point of use. Mobile brick plants are commonly used in a variety of construction projects, including residential, commercial, and infrastructure developments. Their ability to provide bricks precisely where they are needed makes them a valuable asset in the construction industry, improving efficiency and reducing overall project costs.

Request for a quote

TITAN MACHINERY

United Kingdom

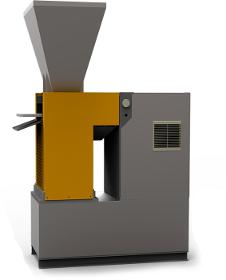

A compact brick machine is a specialized piece of equipment designed for the efficient production of bricks in a relatively small and space-saving footprint. These machines are ideal for small to medium-scale brick production operations, where space may be limited, but the demand for high-quality bricks is still significant. Compact brick machines are suitable for various applications, including residential construction, landscaping, and small-scale commercial projects. They play a crucial role in meeting the demand for quality bricks while offering the advantages of space efficiency and cost-effectiveness.

Request for a quote

TITAN MACHINERY

United Kingdom

The TITAN 600D is a versatile brick and curbstone machine that has gained recognition in the construction industry for its exceptional capabilities. This machine is designed for precision, efficiency, and flexibility, making it an ideal choice for various construction projects. The TITAN 600D is a valuable asset for construction companies and manufacturers seeking to produce bricks and curbstones efficiently and to exacting standards. Its adaptability, precision, and durability make it a top choice for a wide range of construction applications, from residential to commercial and infrastructure projects. Invest in the TITAN 600D for superior brick and curbstone production in the construction industry.

Request for a quote

TITAN MACHINERY

United Kingdom

A sand-lime brick making machine is a specialized piece of equipment designed for the production of bricks made from a mixture of sand, lime, and other additives. These bricks are also known as silica sand bricks or sand-lime bricks and are recognized for their excellent quality and durability. Sand-lime brick making machines are widely used in the construction industry to produce bricks that are known for their strength and resistance to environmental factors. These bricks find applications in various construction projects, including residential, commercial, and industrial buildings. They are valued for their durability and suitability for both load-bearing and non-load-bearing walls.

Request for a quote

TITAN MACHINERY

United Kingdom

The Titan 240D High-pressure brick making machine is a game-changer in the construction industry. With its advanced technology and precision engineering, this machine produces bricks of exceptional quality and strength. It's designed for efficiency and durability, ensuring that your construction projects are built to last. Whether you're a contractor or a manufacturer, the Titan 240D is the key to enhancing your productivity and delivering top-notch results. Invest in this cutting-edge machine and experience the difference it makes in your brick production.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1536 machine is a high-end machine designed for the production of concrete blocks, concrete paverstones and concrete curbstones. ZIM 1536 comes out with high-end hardware, wide options of production and low labor cost. It can be used in automatic facilities such as FINGER CAR, BASKET SYSTEM, L TYPE SYSTEM. Our machine that can produce 15 blocks or 36 paverstones in one press, is designed to produce 1200-1400 pallets per day. Aiming at maximum capacity with mass production, our machine is designed to work non-stop! Our machine, which can follow the mortar in machine with the loadcell system in the bunkers, takes you to the next level with the proportional mortar car movement, and reaches the maximum quality with the mold balancing and pressing system, is a pioneer in the sector with its many hardwares!

Request for a quote

BEYAZLI GROUP

Turkey

PRS 400 SEMI AUTOMATIC MACHINE; Semi Automatic System Is Made Like A Mortar Plant. Machine Is Designed To Work 24 Hours. It Has A Different Automation And Capacity System. Machine Is Very Fast And Has High Production Capacity. By Changing The Mould Machine Can Produce Any Types Of Concrete Paving Blocks - Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks Which Height Must Be Between 5cm And 25 Cm. Equipment List With Prices, Prepared Related To The Installation Layout Is Given Below. Daily Capacity (8 Hours) 4.000 Pieces Concrete Hollow Blocks / 300 M² Paving Blocks… Whatsapp Now: +905326382935 see video below https://www.youtube.com/watch?v=uWEj3G78xwA&t=1s

Request for a quote

BEYAZLI GROUP

Turkey

Campaign Price: 12.685 EURO (free installation and free staff training) Contact: Seher +90 5326382935 (Whatsapp) Warranty: minimum 24 months Capacity: 2250 Concrete Blocks 20 cm width /8 HOURS Transportation : 1 HQ 20' Containers With Single Mortar Hopper - Semi-Automatic or Full Automatic System - Manual Pallet Carrying System - Fully Automatic Mortar System (With Hopper And Cement Silos) - Daily Capacity 2.500 Hollow Blocks of 20 Cm - 1000 m2 Construction Area - Totally Needs 4 kW Energy - It Is An Ideal Machine That Can Be Able To Produce With Max. 4 Persons - Designed To Work 24 Hours. Through Special Vibro Motors Machine Can Produce Every Stone Which Heigh Between 18 / 25 Cm. Video of machine: https://www.youtube.com/watch?v=VQ_2iQm_C0U&t=5s concrete block machine - Hollow block machine - bricks machine - Cinder block machine - Hollow brick machine - Concrete batching plant Optionally

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

Our ZIM 820 machine is a mid-entry machine designed for the production of double-layer paving stones. The ZIM 820 stands out with its low energy consumption, wide choice of production and high return on investment. It can be used manually, semi-automatically and fully automatically if requested. Our machine, which can produce 8 concrete blocks or 20 concrete paverstones in one press, is designed to produce 1000 pallets per day. To facilitate this production and increase quality; It has many features such as internal shaking system in the mortar cart, driver-controlled vibration system, special balancing system on the upper mold, and a specially designed vibration table. We are using “ FULLDRIVE ” frequency controlled vibration systems in our machine. This helps the life cycle of vibration engines and also decreases the total electrical consumption of vibrators.

Request for a quote

BEYAZLI GROUP

Turkey

Concrete Mix Plant - Hollow Block Making Machine - Paving Block Making Machine - Curbstone Making Machine Ready mix concrete plant - Concrete block machine - Paving block machine - Interlock bricks machine - Cinder block making machine - Hollow block machine - concrete block making machine - paving block making machine - interlock brick making machine Campaign Code : C-001 Campaign Price : 52.367 EURO (free installation and free staff training) Contact: Seher +90 5326382935 (Whatsapp Now) Warranty: minimum 24 months Capacity: (8 HOURS) 5.000 Pieces 20 Cm Of Hollow Blocks - 15 m3 / Hour Ready Mix Concrete Transportation : (WITHOUT THE PALLETS ) Max. 1 HQ 40' Container With Single Mortar Hopper - Semi Automatic System - Manual Pallet Carrying System - Fully Automatic Mortar System (Without Hopper And Cement Silos) - Daily Capacity 5.000 Pieces 20 Cm Of Hollow Blocks - 15 m3 / Hour Ready Mix Concrete - Max.

Request for a quote

BEYAZLI GROUP

Turkey

Machine Is Designed To Work 24 Hours. It Has A Different Automation And Capacity System. Machine Is Very Fast And Has High Production Capacity. By Changing The Mould Machine Can Produce Any Types Of Concrete Paving Blocks - Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks Which Height Must Be Between 5cm And 25 Cm. Equipment List With Prices, Prepared Related To The Installation Layout Is Given Below. Daily Capacity (8 Hours) 4.000 Pieces Concrete Hollow Blocks / 300 m² Paving Blocks Video:https://www.youtube.com/watch?v=XemT_7bD_tA

Request for a quote

SCANDINAVIAN & UK MACHINES

Sweden

Capacity – 1 concrete ring in 5-7 minutes. Technical description: Block height floor production: 500-1000 Useful height of machine: 1000 mm Production area: 1500 x 1500 mm Installed electrical power 25 kW Number of high-frequency vibrators: 6 pieces Machine weight with a mold and without a face mix device - 8750 kg Fully automatic model. "Scandinavian & UK Machines" provides full service in mobile and stationary batching plants; block, paving, curbs and wall panels producing equipment; cold asphalt plants; cement unloading equipment supply - consultations, projection, installation, specialists training, service, spare parts delivery.

Request for a quote

SCANDINAVIAN & UK MACHINES

Sweden

The E-12 is a block machine that uses a technique known as “egg laying,” where the block machine moves and produces concrete block products on the ground to dry – We offer the machine in fully/semi-automatic modes. With the SUMAB E-12, the following concrete products can be produced in an efficient way: • Hollow block stones • Solid block stones • Chimneys • Light weight blocks • Paving stones [with vibration table option] *additional option Production capacity: For hollow blocks 400 x 200 x 200 mm ………. 1.200 blocks/h. For hollow blocks 400 x 200 x 120 mm ………. 2.000 blocks/h. We offer Scandinavian quality and good price!

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

The Pars18 Blocks Production line is designed and mad efor more operative and qualified production of blocks. The capacity of Machine per cycle is 18 of 20-th blocks on 1 pallet. Machine is full-automatical and controlled by PLC that is a big advantage for user. The equipment will ensure the production of quality products and operational work by stronger guides, an improved chassis of a Machine and powerful vibration motors. The power used by hydraulic units are playing the main role for production blocks on 140-150 pallets(cycles)/hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

Line of Machine equipment for the production of wall blocks controlled by PLC automation. Machine with a powerful hydraulic configuration, is able to produce blocks into 140-150 pallets per hour. This kind of Machine produces 12 pieces of 20-th blocks in 1 cycle. The batching plant that provide the Machine by mortar is controlled semi/full automatically that’s up to client. The PARS12 blocks making machine has also the operative and quick mold changing system. It makes the machine ideal for producing different kinds of blocks. General Options Easy to install Easy commissioning and repair Pneumatic and hydraulic cylinders Efficient operation with high productivity Low investment and operating costs Easy to clean Opportunity for long-term work System simplicity Reliable emergency system

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce high quality of interlocks, blocks,curbstones and other concrete products as requested by the customer. One press can produce 42pcs of interlocks or 18 pcs from blocks 20x40x20cm block and curbstones. The machine can be used with a stacking system or without stacking system. The press time is 20-24 seconds. It has two working system, it can work either full automatic or semi automatic depending on user preference. Movements on the system will be controlled by a PLC. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood. There are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce interlocks,blocks,curbstones and other concrete products as requested by the customer. In one press it can produce 36 pcs of interlocks, or 12 pcs of 20x40x20cm block The press time is 18-22 seconds. It has two working system, it can work either on full automatic or semi automatic depending on user preference. The machine can be used with a stacking system or without a stacking system. Movements on the system will be controlled by plc. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood there are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed then transported up to the mixer.

Request for a quote

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

YB-1220 represents a new high-tech type of movable egg-laying concrete block machines, produced by Namtas since the beginning of 1980-s. This machine features high throughput and robust easy-to-use design. The machine moves on wheels along straight line on flat even concrete surface according to the specified program while moulding hollow, solid or insulated wall blocks from 185 to 300 mm in height directly on the floor. Delivery of fresh concrete from batching plant to the machine is done by a forklift equipped with a special hopper attachment. YB-1220 does not require production pallets and product handling systems to operate, minimizing customer’s initial financial input and reducing production costs. YB-1220 can be equipped with expanded polystyrene adding unit, allowing it to produce insulated wall blocks.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Namtas fully automatic batching plants are reliable and time-proven pieces of engineering being able to perform at their best in any conditions. They are designed specifically for the preparation of no-slump concrete mix (dry-mix concrete), which is required for the manufacturing of high-quality concrete products. Namtas batching plants can be installed together with Namtas concrete block machines or integrated into already functioning concrete block production plant.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

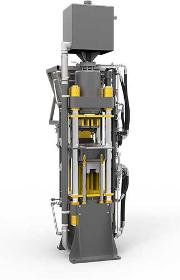

NS-20 is the most compact automatic stationary concrete products machine Namtas manufactures. This reliable time-proven machine is made specifically for those investors and entrepreneurs, who want to start the production of the variety of concrete blocks with minimum financial input, while still being able to manufacture high-quality products, such as paving stones, curbstones, hollow and solid masonry blocks, filler blocks, rain gutters and hardscape elements from 60 to 200 mm in height. NS-20 is integrated in Type A concrete block production plants without automatic cuber. This means cured products should be transferred from production pallets to the transport pallets using manual labour.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

NS-30 and NS-25 are single-layer medium-pallet concrete block machines designed to manufacture high-quality concrete products, such as pavers, curbstones, hollow and solid wall blocks (including lightweight and insulated type), rain gutters and hardscape elements from 60 to 300 mm in height. The main difference between the machines is the size of vibration table, which is slightly bigger in NS-30. This increase machine’s production capacity for pavers and curbstones, as well as allows to produce 1 meter long curbstones lengthwise in the standing position. RIGID DURABLE FRAME AND PNEUMATIC MOULD BOX CLAMPING Both machines has a robust heavy-duty frame welded of rectangular steel tubes 150 x 150 mm. Mould and compaction head carriers are mounted on 4 80mm chrome-plated guiding columns. Mould is attached to the mould carrier via 4 airbags while compaction head is attached to the compaction head carrier via bolts.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Being the best-selling model among all Namtas concrete products machines NS-36 combines durable and reliable design with high throughput and best price/performance ratio. These features contribute to the fast recouping of the capital invested in the machine. Equipped with fast mould changing device, NS-36 is capable of manufacturing a large variety of concrete products, such as paving stones, solid and hollow concrete blocks (including insulated type), filler blocks, curbstones, concrete gutters and hardscape units from 60 to 400 mm in height. HEAVY-DUTY SOLID FRAME Machine frame is a robust heavy-duty structure welded of rectangular steel tubes 150 x 200 mm. Reinforced hard-chromed guiding columns and supporting them linear bearings stabilize the mould and minimize its oscillation.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Combination of company’s experience and modern technology is embodied in a new high-performance large pallet concrete products machine of NT series – NT-36. This machine represents the crowning achievement of a long and laborious work of Namtas’s engineers in collaboration with The Scientific and Technological Research Council of Turkey. Following years of research and tests this machine was successfully launched into production in 2015. This multi-purpose machine is designed to manufacture a large variety of concrete products including pavers, hollow blocks, filler blocks, curbstones, rain gutters and hardscape elements from 60 to 500 mm in height.

Results for

Brick-making - machinery and equipment - Import exportNumber of results

55 ProductsCountries

Category

- Brick-making - machinery and equipment (34)

- Dairies - machinery and equipment (12)

- Cheese-making machinery (10)

- Concrete mixers (8)

- Concrete blocks (7)

- Tile-making - machinery and equipment (5)

- Food industry - machinery and equipment (4)

- Wine-making - machinery, equipment and plants (4)

- Confectionery - machinery and equipment (3)

- Oenology - machinery and equipment (3)

- Bakery - machinery and equipment (2)

- Concrete preparing - machinery and equipment (2)

- Packing and packaging - machinery and equipment (2)

- Bottling and filling - machinery and equipment (1)

- Concrete, ready-mixed (1)

- Distilling - machinery and equipment (1)

- Ice cream-making - machinery and equipment (1)

- Yoghurt-making machinery (1)