- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection production

Results for

Injection production - Import export

ATIL-SAN AUTOMOTIVE MANUFACTURING & INDUSTRY

Turkey

We have OE prodcution and we are supplier of many foreign and local companies. We have E-Mark for our mirrors.

Request for a quote

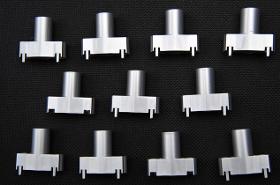

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic molded parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic molded parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. Plastic injection molding is suit to complicated plastic parts with complex profile or structure, welcome contact us for quoting!

Request for a quote

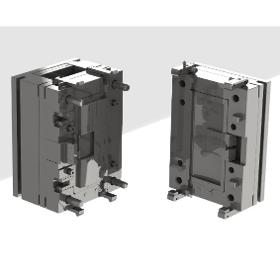

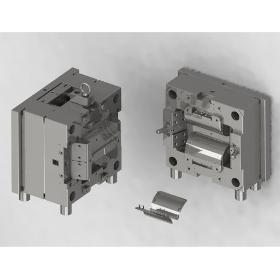

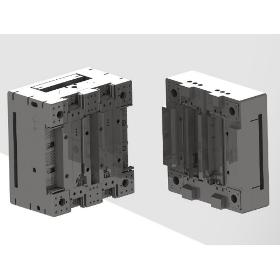

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

One of the most popular sectors in the field of Injection Molding and Plastic Injection is the Automotive Sector. In general, the majority of automotive accessories consist of plastic and rubber. This is the most important indicator that injection molds and plastic injection products maintain their value. The markets formed in the global world have almost taken on the nature of domestic markets, and competition between countries has gained momentum. AYBERKSAN Plastic Mold Industry takes the necessary steps one by one, with quality and corporate awareness, for its goals to become a brand in both local and world markets.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Most of the plastic products are produced by injection method. Injection in summary; It is the process of injecting the melted raw material into the mold at a certain temperature and proportion and obtaining the plastic product after it cools. It is a method widely used in Turkey and in the world. As AYBERSAN Plastik Kalıp Sanayi, we also house the plastic injection process, which is an indispensable part of our injection mold production, within our company. Plastic injection; raw material amount, machine temperature, runner temperature, cooling time etc. It is a process that includes many factors at the same time. If it is not done by experts, there may be burrs, depressions, bursts, etc. in the product. undesirable consequences are inevitable. Our company, which sees quality and satisfaction as equivalent, has made and continues to make all necessary investments in this regard.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Injection mold production is a complex process that cannot be underestimated. The resulting product is the main element to be used in injection molding machines. Therefore, at every stage of the process, there are improvements that need to be made in line with the research and the data obtained from these researches. The R&D process, which started with the examination of the samples we received, continues at the design and injection stages. As AYBERKSAN, our aim is not to present a large number of products with the existing data, but rather to increase the data we have and to present better quality, problem-free and economical solutions. The process we call development cannot happen without research. With this awareness, we, as AYBERKSAN Kalıp Sanayi, continue our research to take the experience we have gained so far to the next level, to add a new one and to develop it.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHMITTER HYDRAULIK GMBH

Germany

Category Diesel technology / Service parts for injection pipes / Union nuts for injection pipes Product number supplier 244004

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Category Diesel technology / Service parts for injection pipes / Union nuts for injection pipes Product number supplier 244002

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Drilling works in our country started with the establishment of MTA in 1935. With the 1950s, drilling applications started not only in the field of oil extraction, but also in the field of mining and natural resources. After the 1970s, the number of private drilling companies has increased and today it is over 1000. With the development of the drilling industry, the use of plastic injection products has increased. The parts, which are mostly called plastic gaskets and felts, are produced and used as plastic injection. Molds of gaskets made of rubber are also produced within our company and product prints are taken. Rubber and plastic seals etc. belonging to the equipment used in this sector. As AYBERKSAN Kalıp Sanayi, we bring the products together with the end user.

Request for a quote

MAGICAL FILM ENTERPRISE CO., LTD.

Taiwan R.O.C.

PETG has high transparency and good adhesion for printing, could be used for makeup bottles, containers, package film and etc. Mixed Polymers can also be extruded into sheet or films, made into plastic products by injection molding, or processed into Christmas tree leaves. Mixed Polymers can be mixed with virgin material, such as ABS, PP, PS and PMMA to extrude or inject plastic products.

Request for a quote

EC PLAZA

South Korea

BUMPER, R/GRILLE, CVR-COWL TOP PNL-INSTRUMENT, TRUNK-LID, LUGG SIDE TRIM, FLOOR-CONSOLE, DOOR TRIM automotive plastic injection molding focusing on large parts such as bumper, grille, lining, etc. Based on 1600 to 3000 ton injection molding facility in prototype development export sector We are achieving the shortest production period of 30 days. Plastic injection parts for Automobile interior and exterior The mechanical know-how of internal and external plastic injection molding products provides high-quality products. ZAS(Zinc Alloy Steel) Use ZAS instead of steel as mold material Spec: BUYERS STANDARDS

Request for a quote

PACA GMBH

Germany

Optisys Petrol and Optisis Diesel are an efficient cleaner and dispersant in one, which reduce and dissolve deposits in injection nozzles. The products support the maximal efficiency of the combustion chamber and reduce exhaust emissions. In addition, they promote engine cleanliness, offer the best protection against wear and give an all-round smooth performance. Optisys Diesel also gets rid of knocking noises. Field of application Every sort of motor vehicle Usage Optisys Petrol and Optisys Diesel are self-mixing. Pour the entire contents into the empty tank, then refuel. Then drive as normal, refilling only when necessary. Batch quantity/Packaging units Batch quantity: 300ml plastic bottles with screw cap Packaging units: 24 bottles per box

Request for a quote

RUDOLF GUTBROD GMBH

Germany

Applicable as Non-stick coating also used for high-temperature applications up to 350°C • Typical layer thickness approx. 20 – 40 μm • Pencil hardness 9H • Clearance certificate for contact with food available Easy-to-clean coating also used for high-temperature applications up to 350°C • Typical layer thickness approx. 5 – 10 μm • Pencil hardness 9H • Clearance certificate for contact with food available Light corrosion protection Typical applications - Foodstuff industry - Bakery industry - Chutes, conveying systems, rollers - Injection moulding, moulding production - Heating plates, heating mirrors - Blades - Varnishing troughs - Impellers - Heat exchanger - and more besides

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

AYBERKSAN Mold Industry, which continues its activities in the Injection Mold Sector; As it developed itself in R&D and Design, it was inevitable that it would receive demand from various sectors. It has offered many products as injection molds and plastic injection to board games equipment.

Request for a quote

RAMIREX - PLASTICOS DE AGUEDA, LDA.

Portugal

Ramirex - Plasticos de Agueda, Lda is a Portuguese company with 40 years of experience in the plastic injection field. We produce our products using our own moulds and exclusive items using our client's moulds. We offer a wide range of products, from furniture accessories (sofa feet, tailor made shutter doors, caps and heads), drawing and office material (set squares, rulers, protractors, letter trays, pen cups and magazine racks) and sealing material (holders and heads). We also manufacture technical parts for different areas (for exemple, for refrigeration equipment, electrical panels and different telecommunication devices), with design and development thay may be either internal or external, according to the requirements of each client. We are a specialized and dynamic technical team, that combines the experience in production of plastic injection parts.

Request for a quote

RAMIREX - PLASTICOS DE AGUEDA, LDA.

Portugal

Ramirex - Plasticos de Agueda, Lda is a Portuguese company with 40 years of experience in the plastic injection field. We produce our products using our own moulds and exclusive items using our client's moulds. We offer a wide range of products, from furniture accessories (sofa feet, tailor made shutter doors, caps and heads), drawing and office material (set squares, rulers, protractors, letter trays, pen cups and magazine racks) and sealing material (holders and heads). We also manufacture technical parts for different areas (for exemple, for refrigeration equipment, electrical panels and different telecommunication devices), with design and development thay may be either internal or external, according to the requirements of each client. We are a specialized and dynamic technical team, that combines the experience in production of plastic injection parts.

Request for a quote

RAMIREX - PLASTICOS DE AGUEDA, LDA.

Portugal

Ramirex - Plasticos de Agueda, Lda is a Portuguese company with 40 years of experience in the plastic injection field. We produce our products using our own moulds and exclusive items using our client's moulds.Visit our website to get our catalogue.

Request for a quote

RAMIREX - PLASTICOS DE AGUEDA, LDA.

Portugal

Ramirex - Plasticos de Agueda, Lda is a Portuguese company with 40 years of experience in the plastic injection field. We produce our products using our own moulds and exclusive items using our client's moulds.Visit our website to get our catalogue.

Request for a quoteResults for

Injection production - Import exportNumber of results

185 ProductsCountries

Company type

Category

- Plastics moulding (88)

- Metal furniture (27)

- Automobile - assistance (7)

- Packing and packaging - machinery and equipment (7)

- Injection moulding of rubber and plastic (4)

- Beauty products (3)

- Oilseed crops (3)

- Drilling services (2)

- Gloves (2)

- Polymers (2)

- Blow moulding of rubber and plastic (1)

- Board games (1)

- Bumpers (1)

- CAD/CAM Computer Assisted Design/Computer Assisted Manufacturing - software (1)

- Carwash systems (1)

- Casting, steel (1)

- Cement-making - machinery and equipment (1)

- Damaged goods - recovery and recycling (1)

- Electrical & Electronic Components (1)

- Films, plastic (1)