- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water treatment- industrial - systems and equipment

Results for

Water treatment- industrial - systems and equipment - Import export

IGUS® GMBH

Germany

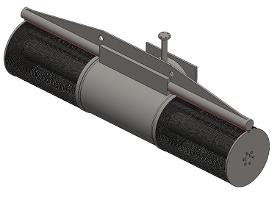

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

FLOTTWEG SE

Germany

Honored with the German Innovation Award 2019, the Xelletor series is one of the greatest achievements in the field of sewage sludge. Dewatering sewage sludge is standard for wastewater treatment plants and since it usually has to be transported away, operators have an interest in separating as much water as possible from the sludge. This saves weight and thus reduces costs. Savings of up to 10% in sludge volume and 34% in energy consumption are possible. Our Xelletor high-performance centrifuge inspires customers all over the world with the many years of technical know-how and innovative spirit behind it.

Request for a quote

FLOTTWEG SE

Germany

Proven know-how meets state-of-the-art technology. This is the best way to describe the new Flottweg decanter C series. We also have the optimal solution for the very large wastewater treatment plants. The combination of our own Simp Drive® drive system, which has been in use since 1994, and Recuvane®, which allows flexible and simple retrofitting as well as targeted discharge of the centrate water, sets new standards for Flottweg in separation technology.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

Intake screen also called T-screen is used to intake and clear water in many industrial areas. They are commonly used in hydroelectric, agricultural, drinking applications to prevent dirty materials from the water. Intake screen is commonly used in lakes known as lake pump intake screen. Intake water works as passive intake screen to intake of water for generating electricity for hydropower. Water intake filter screens can intake clean water by eliminating unwanted materials. Because of its simple cleaning, major maintenance is not required for the operational time. Advantages: 1-High performance water filtration 2-Fish friendly 3-Corrosion resistance 4-Passive intaking water 5-High durability – less maintenance 6-Easy to install Applications: 1-Hydropower Intake 2-Lake Application 3-River Application 4-Water Cleaning

Request for a quote

FLOTTWEG SE

Germany

Flottweg C series decanters around the world process 25 million liters of sewage sludge per hour. The dewatering and thickening of sewage sludge plays a decisive role in the wastewater treatment process. Requirements for the quality and efficiency of sewage treatment plants increase year after year, not least driven by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially for this purpose. The C7E represents the largest of all the C machines. The C7E increases the proportion of dry substance in the sludge, thereby reducing its volume and weight (due to loss of water). That means that operators need to dispose of, recycle, or burn less sludge. The result: enormous potential savings for the operators of sewage treatment plants.

Request for a quote

FLOTTWEG SE

Germany

Innovationen sind Flottweg Spezialität. Unsere Xelltorbaureihe spiegelt Erfindergeist, langjährige Erfahrung und technisches Know-How in einer Maschine wieder. Auf Kläranlagen ausgelegt ist die X5E für mittelgroße Kläranlagen die optimale Lösung, wenn es um Schlammentwässerung und Schlammeindickung geht. Die Kosteneinsparung hinsichtlich Entsorgung und Transport ist für viele Kläranlagenbetreiber der ausschlaggebende Punkt, sich für den Flottweg Xelletor zu entscheiden.

Request for a quote

FLOTTWEG SE

Germany

Flottweg has developed a unique centrifuge concept especially for the high-level dewatering of sewage sludge: The Flottweg Xelletor series. For the wastewater treatment plant operator, dewatering offers enormous savings potential. The costs for transport and disposal of dewatered sewage sludge often account for 80% of the operating costs of mechanical dewatering. The dewatering performance of the Xelletor machine is significantly better than that of our predecessor models. And it's setting new standards in terms of throughput, dry substance, and polymer and energy consumption.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages 1-Special surface treatment 2-Suitable & customizable design 3-Long service life 4-High durability – less maintenance 5-Effective filtration Applications 1-Food and Mineral Processing 2-Water Cleaning 3-Mining Applications 4-Vibrational Separation 5-Fermentation 6-Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

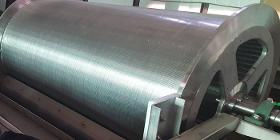

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: 1-High filtration performance 2-Customized bend screen design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap 6-High capacity compared to panel wedge wire screen Applications: 1-Mining process 2-Water treatment 3-Food processing 4-Particle filtration 5-Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as: 1-Special surface treatment 2-Modular and customizable design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap Applications: 1-Water Treatment 2-Mine, coal, mineral Processing 3-Food and Beverage 4-Petrochemical and oil

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The standard model is made with wetted parts manufactured in AISI 304, the support legs in treated and painted carbon steel, filter element of quartz sand of suitable grain size. Special executions and alternative materials are available on request. Typical applications: tertiary treatment of civil and industrial waste water, surface water clarification, treatment of drinking water, primary filtration of civil and industrial waste water, clarification of metallurgical industry cooling water, algae removal, pre-treatment for ultra-filtration membrane installations, pre-treatment for ozonisation plants, finishing treatment with active carbon. - Low first costs and plant management costs - High efficiency and reliability for the removal of suspended solids, even colloidal - Exclusive backwash system which uses raw water rather then filtered water - External sand recirculation system - Ease of installation Possibility of gravity feed, thanks to its low pressure drops

Request for a quote

MITA WATER TECHNOLOGIES

Italy

Mitadaf is an innovative dissolved air flotation system. Its exceptional solid/liquid separation and/or sludge thickening efficiency is the result of the combined systemof uniform hydrodynamics and filtration with a bed of micro air-bubbles: an equipment of new concept developed by MITA. The heart of the mitadaf system is the multifunctional central column, by means of which the raw sewage is introduced into the tank, the clarified effluent water is recovered and the sludge exits. The raw influent water, suitably saturated with air, is introduced into the flotation tank via a series of holes located in the lower part of the central column. The entering mix, propelled by the micro-bubbles of air, immediately reaches the surface, homogeneously distributed across the whole flotation area (uniform hydrodynamic system).

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The flow of oil and water is introduced to the tank and distributed in a homogeneous way across the whole cross-section. They are composed of a containment tank which can be manufacturedfrom treated and painted carbon steel or AISI 304 stainless steel; lamellar pack with parallel channels in rigid polystyrene, stabilized agains UV radiation. Special materials and executions are available on request. Typical applications: first fall rain water, petrochemical plants, mechanical workshops, refineries and depots of hydrocarbons, washing of vehicles, land reclaim, refuse handling centres. -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MITA WATER TECHNOLOGIES

Italy

The flow of water and sludge coming from the previous phases of treatment (whether biological or physical-chemical) is introduced into the intermediate zone of the tank, just below the lamellar pack. Lamellar pack single-piece clarifiers for the sludge settling. They are composed of: containment tank which can be manufactured from, at choice, treated and paintedcarbon steel or in AISI 304 stainless steel; lamellar pack with parallel channels in rigid polystyrene, stabilized against UV radiation; surface discharge trough (with weir) in AISI 304; intermediate distributor of the feed flow. Special materials and executions are available on request. FM – L SERIES (11,30 m2/m3 equivalent surface) Typical applications: secondary clarification of biological sludge, drinking water plants, upgrading of existing clarifiers, rain water treatment. -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The flow of water and sludge coming from the previous phases of treatment (whether biological or physical-chemical) is introduced into the intermediate zone of the tank, just below the lamellar pack. Lamellar packs with frame for sludge removal. They are composed of the parallel channel lamellar pack in rigid polystyrene, stabilized against UV radiation, closedin an AISI 304 containment frame; they are normally employed for the upgrading of existing clarifiers or for housing in concrete tanks specifically built for the purpose of holding lamellar packs. F – L SERIES (equivalent surface 11,30 m2/m3) F – I SERIES (equivalent surface 14,90 m2/m3) F – S SERIES (equivalent surface 20,00 m2/m3) -High solid-liquid separation efficiency -Simplicity of installation and operation -Compact execution -Low first costs and plant management costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The advantages of cloth filters and biorulli in a compact system for small community water treatment. Compact system for the biological purification treatment with biodiscs combined with cloth filter for the separation of excess sludge. The biocombi compact system features two treatment phases (biological treatment and separation of excess sludge) gathered in a single tank. The standard model provides the complete provision of a carbon steel tank treated and painted with a fiberglass modular cover easily removable, and an electrical switchboard on the machine with IP 55 protection. The moving parts (disc roller and drum filter) are actuated by a single geared motor with power included between 1,10 and 1,50 kW. -Minimum energy consumption -Reduced maintenance -Easy accessibility -Increased floor space (compact construction)

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The advantages of cloth filters and biorulli in a compact system for small community water treatment. Compact system for the biological purification treatment with biodiscs combined with cloth filter for the separation of excess sludge. The biocombi compact system features two treatment phases (biological treatment and separation of excess sludge) gathered in a single tank. The standard model provides the complete provision of a carbon steel tank treated and painted with a fiberglass modular cover easily removable, and an electrical switchboard on the machine with IP 55 protection. The moving parts (disc roller and drum filter) are actuated by a single geared motor with power included between 0,75 and 1,10 kW. -Minimum energy consumption -Reduced maintenance -Easy accessibility -Increased floor space (compact construction)

Request for a quote

MITA WATER TECHNOLOGIES

Italy

Biodisc bio-oxidation system. Compact and modular solution, minimum energy consumption. B290 is the series of the largest units, used for plants of significant size. The transport of these rotating contactors is of the special category, but still at acceptable costs (it does non necessitate police escort). Typical applications: medium-sized communities and large factories. -Compactness and adaptability of the installations thanks to the limited dimensions -Modular installation, which allows subsequent plant expansion -Simplicity of plant management and maintenance: no need for specialist personnel -Low energy consumption, with consequent reduction of operating costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

Biodisc bio-oxidation system. Compact and modular solution, minimum energy consumption. B240 is one of the most recent series, designed to optimise the experiences acquired with the other types. It offers a range of medium to high active surfaces whilst being of limited size which facilitates their handling and installation. The series is already favoured in various installations, both civil and industrial. -Compactness and adaptability of the installations thanks to the limited dimensions -Modular installation, which allows subsequent plant expansion -Simplicity of plant management and maintenance: no need for specialist personnel -Low energy consumption, with consequent reduction of operating costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

Biodisc bio-oxidation system. Compact and modular solution, minimum energy consumption. B200 is the most used series, considering that it was the first to be launched and manufactured 40 years ago. It covers the size of plant in which the advantages of the biorulli® system are most evident. Typical applications: from small to medium-sized communities with seasonal variations in the number of inhabitants. -Compactness and adaptability of the installations thanks to the limited dimensions -Modular installation, which allows subsequent plant expansion -Simplicity of plant management and maintenance: no need for specialist personnel -Low energy consumption, with consequent reduction of operating costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

Biodisc bio-oxidation system. Compact and modular solution, minimum energy consumption. This is the latest entry to the single-piece unit series. The tank is made from treated and painted carbon steel, the cover in fibreglass-reinforced polyester. It associates the advantages of a single-piece unit (simplicity of installation, limited civil engineering works) with the possibility of application in installations already of a considerable size. The transport of these single-piece units is of the special category, but still at acceptable costs (it does not need a police escort). Typical applications: small to medium-sized communities various types of industry -Compactness and adaptability of the installations thanks to the limited dimensions -Modular installation, which allows subsequent plant expansion -Simplicity of plant management and maintenance: no need for specialist personnel -Low energy consumption, with consequent reduction of operating costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

Biodisc bio-oxidation system. Compact and modular solution, minimum energy consumption. This is the most widely used single-piece unit series. The tank can be made, at choice, in treated and painted carbon steel or in AISI 304 stainless steel. The cover, in both cases, is manufactured in fibreglass-reinforced polyester. It is noteworthy for the ease of installation (limited civil engineering works, factory-assembled unit). Typical applications: hotel villages small communities various types of industry -Compactness and adaptability of the installations thanks to the limited dimensions -Modular installation, which allows subsequent plant expansion -Simplicity of plant management and maintenance: no need for specialist personnel -Low energy consumption, with consequent reduction of operating costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

Biodisc bio-oxidation system. Compact and modular solution, minimum energy consumption. M115 is the smallest single-piece unit series. It involves a set of rotating discs complete with tank and cover, both manufactured from fibreglass-reinforced polyester. It is an economical version, easy to install. Typical applications: apartment blocks villas small campsites factory premises -Compactness and adaptability of the installations thanks to the limited dimensions -Modular installation, which allows subsequent plant expansion -Simplicity of plant management and maintenance: no need for specialist personnel -Low energy consumption, with consequent reduction of operating costs

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The best solution for tertiary filtration: high solid removal yields, minimum water and energy consumption. The tertiary filtration is strongly influenced by the hydraulic profile of the plant, which often cannot be changed. In the PECV VM (VM = metal tank) disc filters series the collection shaft is placed vertically. The goal is to feed equipment completely submerged even with very low hydraulic profiles. Even for this series, cloth washing is done with pumps, each of which is served by two or more discs. The pumps are actuated in sequence in order not to disrupt the functionality of the system. The PECV VM solution is ideal for small-medium unattended systems with heavy and extremely variable loads. The largest model of this series can process a load equal to a community of approximately 10.000 PE. The various models can be installed in parallel to obtain various working capacities. - Gravity filtration with limited head loss.

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The best solution for tertiary filtration: high solid removal yields, minimum water and energy consumption. The PPC – PPC VM (VM = metal tank) series was developed for plants with medium-large potential. For filters in this range, cloth washing is done with two pumps only (of which one backup pump) which serveall the discs. The selection of discs on which to conduct the backwash (in sequence) is carried out by using double-acting valves with pneumatic control. The largest standard model in this series has a filtering surface of 160 m2 that can process a load equal to a community of approximately 50.000 PE. A singular feature of this series is the low energy consumption, even more noticeable with the increasing plant potential. - Gravity filtration with limited head loss. - Continuous filtration without standby units for the backwash phases. - Cloth filter in polstoff free fibre provided with high mechanical strength.

Request for a quoteResults for

Water treatment- industrial - systems and equipment - Import exportNumber of results

55 ProductsCountries

Company type