- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bearings- ball

Results for

Bearings- ball - Import export

LANDA SAS

France

Discover our range of bearings for agricultural equipment: ball bearings, roller bearings, cam rollers, needle bearings. To provide you with the most comprehensive range and impeccable quality, we work with the leading brands of agricultural bearings: Timken, NTN, SNR, NSK and Schaeffler. Our range includes more than 1,000 items, 450 of which are in stock. Landa offers a range of agricultural parts for forage harvesters, combine harvesters, balers, mower conditioners, windrowers and tedders. We develop wear parts for harvesting machines that are equivalent to original manufacturer parts, in partnership with industrial companies specialising in the fields of metallurgy (assembly, machining, forming).

Request for a quote

WIB SA

Switzerland

Packaging is a very important parameter for the retention of the bearing quality during transport and storage. It is designed to protect the bearings against corrosion, dust, and other pollutants. Apart from that, each unit is labeled and carries all the relevant information concerning the technical and quality features of the bearing. The production batch number is printed on the label and guarantees the traceability of the product, as well as the identification of the manufacturing date. Therefore, it is advisable to unpack the ball bearing only prior to use or assembly.

Request for a quote

WIB SA

Switzerland

The noise level is an important quality criteria of a ball bearing. It mainly depends on the following factors: precision of the geometric forms surface finish of the raceway and the balls cleanliness of the bearing type of lubricant type of cage rotational speed

Request for a quote

WIB SA

Switzerland

It is even possible to apply a coating on the outer ring, before assembling the bearing, thus guaranteeing the best possible geometrical forms. The machining of grooves ensures that the coating perfectly adheres to the metal surface. Additionally, a wider temperature range may be covered.

Request for a quote

WIB SA

Switzerland

By applying surface treatments on outer ring contact surfaces, it is possible to improve certain mechanical characteristics such as the hardness. By doing this, we can increase wear resistance while decreasing the friction coefficient. With certain treatments it is possible to achieve high resistance to specific chemical agents. The table below shows a small sample of examples of such surface treatments and their resulting technical characteristics.

Request for a quote

WIB SA

Switzerland

The resistance generated by the seal (if present), depending on the surface finish of the outside diameter of the inner ring, as well as of the rotational speed. The resistance generated by the cage, depending on the geometrical form and the machining quality of the cages. The resistance generated by the lubricant, depending on the lubricant viscosity and filling quantity as well as the rotational speed. At low speed and with fine instrument oil this resistance is insignificant. It will be higher at low temperatures and at high viscosity of the lubricant. Grease lubricated bearings will show, according to the grease type and filling, a much higher friction torque than oil lubricated bearings.

Request for a quote

WIB SA

Switzerland

The 100 Cr6 steel rings manufactured by WIB are stabilized after hardening by annealing. As a result of this treatment, they can be used at temperatures of up to 150°C. They have a hardness of 60 to 64 HRC For applications operating at high temperatures or in order to reduce their sensitivity to shock loads, it is necessary to stabilize the rings at higher temperatures after hardening. It should be noted that such a stabilization will slightly reduce the hardness of the rings.

Request for a quote

WIB SA

Switzerland

The radial clearance is not considered a quality criterion. An improper radial or axial clearance may have detrimental implications during operation within an application. This may include suboptimal noise levels, heat generation, rigidity, and fatigue life. Prior to recommending an internal clearance range, our applications will run an analytical simulation on the bearing and application to ensure optimal performance. For more complex system, our application engineers can complete a FEA analysis, particularly when evaluating multiple bearings within a non-rigid housing.

Request for a quote

WIB SA

Switzerland

The primary function of a lubricant is to lubricate the rolling and sliding contacts of a bearing to enhance its performance through the prevention of wear. This can be accomplished through various lubrication mechanisms such as hydrodynamic lubrication, electrohydrodynamic lubrication, and boundary lubrication.

Request for a quote

WIB SA

Switzerland

Certain applications call for special tolerancing to ensure optimal performance, which WIB is accustomed to accommodating. Dimensions that fall outside international standard will be identified with a PA designation, which appears in the descriptions and drawings. Special PA tolerances may be combined with standard tolerances when one or more tolerances are not referenced in the standards. These tolerances are shown on the bearing drawings as well. This is primarily used for bearings with profiles. For example: P0/PA

Request for a quote

WIB SA

Switzerland

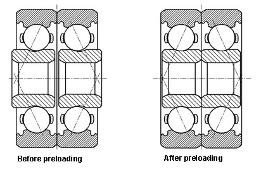

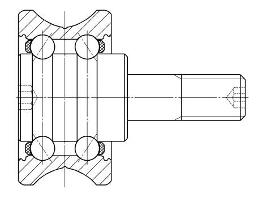

Pairing is achieved with bearings of identical tolerance classes and by applying an axial preload to the inner rings for the O arrangement and on the outer rings for the X arrangement. The inner or outer rings are undergo a separate grinding operation to align both side faces on the same plane with minimum clearance.

Request for a quote

WIB SA

Switzerland

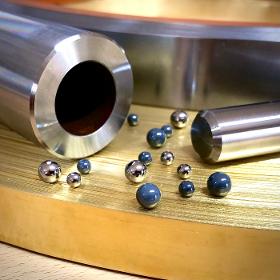

Cages are used to position and keep the balls distanced from each other at the pitch circle diameter. We offer a variety of different cage architecture and material tailor for each customer application. Cages are constructed of brass, steel, or synthetic materials. Brass and steel cages are manufactured at WIB. We also manufacturing our own tooling and can adapt cage designs to meet the requirements of the application. For certain applications, ball bearings without cages or full complemented bearings are manufactured.

Request for a quote

WIB SA

Switzerland

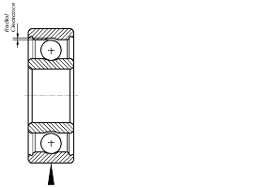

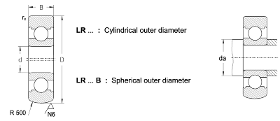

For certain applications, it may be appropriate to use ball bearings fitted with a snap ring fixed on the outer ring. The dimensions of the N groove and the snap ring R are are defined by the ISO 464 standard. The bearing is available in two versions, according to the customer’s requirements.

Request for a quote

WIB SA

Switzerland

Each bearing is designed around the application it is used in and sometimes that include a profile on the inner or outer ring. We have an array of profiles that we can use on our bearings, including common ones listed below or something completely unique to your application. In collaboration with our application engineers, we will work with you to ensure the right profile, tolerances, material, surface finish, and even the harmonics of the profile are fine-tuned to ensure quite operation, even at high speeds.

Request for a quote

WIB SA

Switzerland

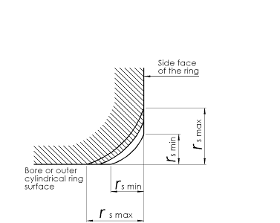

To ascertain proper mounting of the bearing on the shaft and housing while ensuring maximum surface contact area, the proper fillet radius must be used. Too small and the bearing will not sit flush against the shoulder, too large and we forego precious surface area to reinforce the support. Done right, the optimal surface area is used while avoiding any chance of interference between the fillet and the shaft or housing.

Request for a quote

WIB SA

Switzerland

We offer a wide range of material depending on the needs of the application. When working with our application engineers, we will select the material type (and heat treatment method) to ensure the bearings meet the requirements of the application. This includes factors such as high wear resistance, heavy shock loads, extreme corrosion, as well as dimensional stability.

Request for a quote

WIB SA

Switzerland

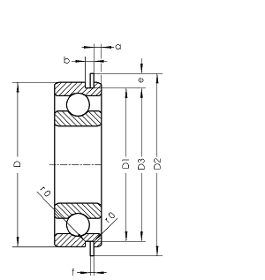

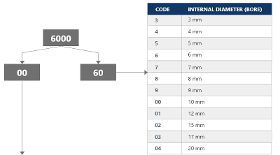

At WIB, we produce all subcomponents, including inner and outer rings, brass and steel cages, as well as the shields to the highest quality standards. Our Performance Bearings are manufactured to ISO, ABMA, DIN, and BS international standards while our Custom Bearings are tailored specific for each application. The Performance Bearing nomenclature is described below.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIB SA

Switzerland

You’re developing advanced technologies that keep your business and your industry moving. When it’s time to move beyond standard bearing to custom ball bearings solutions designed for uniquely challenging applications, WIB is a world-class partner.

Request for a quote

WIB SA

Switzerland

Only bearings specifically developed for each application will cope optimally with the required specifications. With our wide experience in the field of working with such challenges, WIB is uniquely positioned to offer the most appropriate solutions. We have developed application specific solutions through extensive R&D efforts carried out in collaboration with our customers. It is through such joint effort that the quality of the final product has been improved to constantly meet evolving market demands.

Request for a quote

WIB SA

Switzerland

As the leading manufacturer of linear guide system bearings, WIB works collaboratively with customers on the development of common and tailor designs, supplying the best-in-class technical and commercial solution for each unique application. Each parameter, including environmental factors, precision requirements, speed, temperature, load, boundary dimensions are thoroughly evaluated during the design and development phase.

Request for a quote

WIB SA

Switzerland

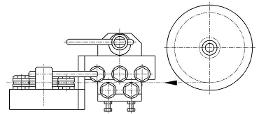

The manufacturing precision of the roller has a major influence on the quality of the final product (wires) as well as on the service life of the rollers. It is therefore essential that the ground “V” groove on the outer ring is machined and positioned precisely relative to the internal geometry. WIB only produces straightener roller bearings produced in this fashion, while many other producers machine the outer wire guide groove after assembly

Request for a quote

WIB SA

Switzerland

These track rollers offer the same features of a single row track roller with the added benefit of heavy radial, thrust or combined loads. Yoke-type track rollers are single or double-row units mounted on shafts or studs. Similar to the single row track roller, we can customize the running surface to meet the specific requirements of the applications. Cam rollers are similar in their construction to single and double-row support rollers, except that the raceway is formed by a heavy-section roller stud with a fixing thread. The most common running surface profiles can be found on the Special Profiles page under Technical Parameters.

Request for a quote

WIB SA

Switzerland

Track rollers—also referred to as idler rollers—are motion transmission components designed to work with all varieties of tracks. They are used in conveyor systems, cam drives, and a wide range of similar material handling systems. Regardless of the material or machine, these components play a critical role in track and rail operations. When selected, employed, and maintained properly, they facilitate system operations, allowing for greater speed and efficiency. Single row track rollers are available with spherical outer ring running surfaces or cylindrical (or flat) outer ring running surfaces. View our page of Special Profiles found under Technical Parameters for some of the more common profiles on the running surface.

Request for a quote

WIB SA

Switzerland

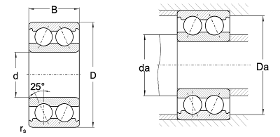

Double-row angular contact ball bearings are used in applications when heavy radial, thrust or combined loads demand axial rigidity of the shaft are required. This is similar to a duplex pair of single- row bearings due to its two rows of balls and angular-contact construction, which provide greater axial and radial rigidity than can be obtained by using a single-row radial bearing. We manufacture these ball bearings with a minimum bore diameter of 3 mm to a maximum outer diameter of 47 mm.

Request for a quote

WIB SA

Switzerland

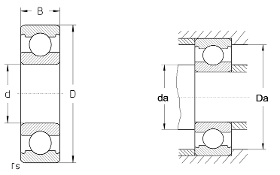

Although single row radial bearings are designed primarily to support a radial load, they perform relatively well under thrust or combined radial and thrust load with the added advantage of low noise, vibration, and drag torque. The internal architecture and cage selection can be designed to meet the specific needs of the application, from high speed to high load. Thin section deep groove ball bearings have a small radial cross-sectional thickness that are used when compactness is required. We manufacture deep groove ball bearings with a minimum bore diameter of 3 mm to a maximum outer diameter of 47 mm.

Request for a quote

WIB SA

Switzerland

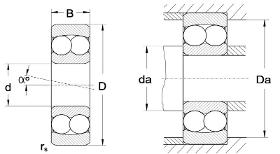

Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring. This type of ball bearing is recommended when alignment of the shaft and housing is difficult, and the shaft may flex. Unlike a single row or double row ball bearing, the self-aligning bearing’s performance will not be affected by misalignment. Therefore, they are particularly suitable for application where misalignment can arise from errors in mounting or shaft deflection inherent in the application. These bearings are made with seal or without seal.

Request for a quote

WIB SA

Switzerland

Closures, more commonly known as shields and seals are used to protect the internal parts of the bearing against dust, liquid, and gaseous particle contamination. The shields help contain the lubricant in the bearing but are not designed to keep out liquid and gaseous contamination. We manufacture our own shields at WIB to the precise tolerance to minimize the opening gap, thereby offering great grease retention and longer life. On the other hand, seals are designed to keep various types of contamination out, keeping the grease clear of foreign particles and extending the bearing life.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO LBalls are selfaligning Spherical Bushings consisting of a special zinc diecast alloy body and a studded ball which has its axis at right angles to the body. They can perform tilting movement, oscillating movement and rotation with low torque, and transmit power smoothly due to uniform clearance between the sliding surfaces. Their superior wear resistance assures stable accuracy for long periods of time, and maintenance is simple. They are very economical bearings. For these reasons, they are widely used in link mechanisms in automobiles, construction machinery, farm and packaging machines, etc.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings to meet – or even exceed – the highest precision classes P4 and ABEC 7. Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity. The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Request for a quoteResults for

Bearings- ball - Import exportNumber of results

664 ProductsCountries

Company type

Category

- Bearings - ball, needle and roller (485)

- Bearings, ball (152)

- Bearings, roller (55)

- Castors, swivelling (16)

- Internal transport systems (9)

- Electric motors and parts (6)

- Rails and sliding frames (5)

- Greases, industrial (4)

- Sliding doors - industrial (4)

- Clutches (3)

- Potentiometers (3)

- Wheels, castors and rollers (3)

- Wheels, castors and rollers - metal (3)

- Connectors, plumbing (2)

- Conveyor systems (2)

- Cylinders, pneumatic (2)

- Engines & Parts (2)

- Lubricants, industrial (2)

- Pallet trucks (2)

- Precision balls (2)