- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire spark-erosion

Results for

Wire spark-erosion - Import export

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

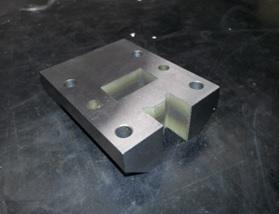

Medium-sized milling

Request for a quote

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quote

STEEC

France

Spark erosion involves removing material from a conducting part and eroding it to give it the desired shapes and dimensions by means of electrical discharges. In the wire sparks erosion process an unwinding metal wire, under tension, is immersed in water or in another insulating liquid (dielectric) with the part to be worked. The current transmitted forms an electric arc which gives rise to precise, programmed degradation of a section of the part. The residues created by wearing of the part are removed by the water or dielectric liquid. STEEC carries out both spark erosion and fine wire micro spark erosion operations Wires spark erosion and machining Equipped with the latest wire spark erosion technologies, STEEC is able to carry high precision cutting with wires of standard sizes whose diameter may vary from 0.15 to 0.25 mm in all types of mechanical parts.

Request for a quote

STEEC

France

This modern machining technology offers a host of advantages over more conventional processes. STEEC makes available to its customers its know-how in micro drilling by spark erosion. The principle of this machining process is the same as for wire spark erosion, except that the tool used for cutting is no longer a wire but an electrode shaped according to the precision machining require. The part and the tool (electrode) are not therefore in contact with each other, in fact it is an electric arc formed between the electrode and the part that will machine the latter. This is also called sparking. The part must be necessarily be conducting to be able to be machined by this method and it is prerequisite for using this method. This absence of contact between the tool and the part makes it possible to machine very hard materials such as titanium for example.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AXON CABLE SAS

France

As a specialist in interconnect and process automation, Axon' Mechatronics, a sister company of the axon’ group, offers interconnect solutions such as precision presswork, loose or reeled parts. Solutions Taped and loose parts Pressfit and PIHR (Pin In Hole Reflow) terminals for SMD PC board Complex conductor strips Lead frame SMD terminals and components Terminals for insertion and wave soldering (standard brochure) Advantages Simultaneous engineering : engineering of products and process Integrated tool workshop : Wire and spark erosion machines, grinding machine Stamping presses from 15 to 100 ton Manufacture of parts from 0.1 to 2 mm thickness Processing of all types of complex material Prototyping Applications Industry Consumer electronics Automotive

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

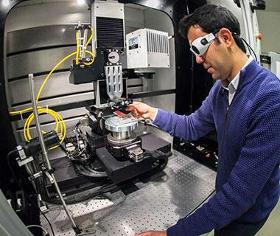

Greatly expand the capability of your EDM machine Stainless steel construction Sealed and fully submersible Light weight and compact The DM series of rotary tables are completely waterproof and are designed for EDM applications. They are built from stainless steel and can be completely submerged. The DME100 table has an a Fanuc absolute encoder to improve precision and is only available as a 4th axis. The DM100 is available with a Kitagawa controller or with a suitable motor to interface with a machine that has already been prepared for an additional rotary axis. Both rotary tables are compact and high precision and will greatly expand the capability of a spark or wire erosion machine. These rotary tables are available with specially designed submersible chucks and tailstocks. RAV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 4th axis preperation.

Request for a quoteResults for

Wire spark-erosion - Import exportNumber of results

8 ProductsCountries

Company type