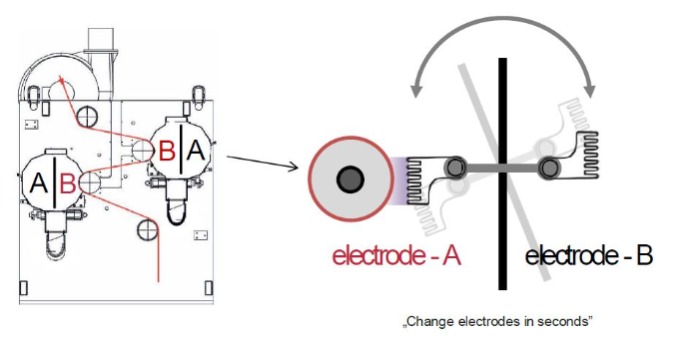

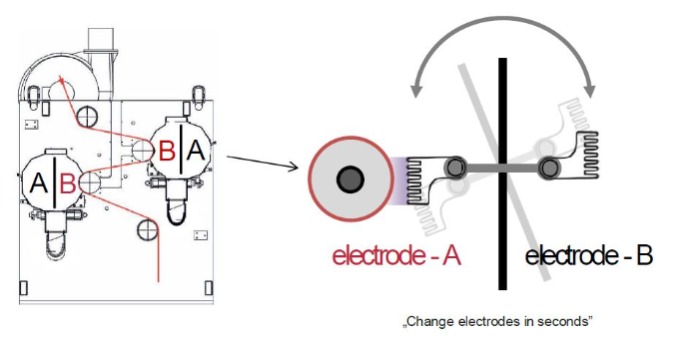

- No downtime during job change - Easily quantifiable return of investment. - Waste reduction - Cleaning work can be done during operation safely and easily - Simultaneous grounding of the inactive electrode(s) - Segments with scale

Germany

Manufacturer/ Producer

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

The effect achieved by the corona treatment is an increase in surface tension to values between 38 to 60 mN/m. Since the surface tension is caused by dispersive and polar interaction components the introduction of polar functional groups in particular increased the polar component of the surface tension.

Request for a quote

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

The Plasmajet® (registered AFS trademark) produces a plasma without a vacuum. The plasma, generated by high voltage in combination with any process gas, is blown out of the unit, and is potential-free. It is used for surface modification. When the plasma comes into contact with a plastic surface, the wettability is increased. Metal surfaces can effectively be cleaned, and it is also possible to weld plastic sheets. The system comprises of a plasma reactor with nozzle, a high-voltage generator with transformer and high-voltage rectifier. The application field for Plasmajet® is mainly where geometric, three-dimensional bodies or profiles are to be coated, printed, glued or cleaned. Typical application examples: Treatment of EPDM profiles for the automotive industry before flocking Treatment of adhesive grooves before gluing the lens of car headlights Treatment of razors and mobile phones before tampon printing Degreasing aluminum profiles before bonding

Request for a quote

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

The compact electrode housings of our treatment stations are used for the reliable extraction of the ozone created by the corona treatment. Exhaust monitoring is an integral part of all corona stations and ensures that a corona discharge can not be activated without suction. The ozone is extracted by a pipe work and discharged to a safe height into the external atmosphere. To reduce the ozone load of the ambient air and comply with local environmental and health and safety regulations the extracted air can be passed directly into an ozone catalyser. Our ozone catalyser is a high performance filter unit designed specifically for ozone destruction in Corona treatment. Since ozone is extremely corrosive, all materials and seals used are corrosion resistant. The housing and all internals are made from corrosion resistant stainless steel. For reliable treatment of the exhaust air, three filter stages are contained within the housing.

Request for a quote

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

AFS corona generators are THE standard for foil extrusion and the packaging industry. It is not without reason that the largest machine manufacturers opt for AFS as their standard equipment. The initial investment cost of any system is only part of the total running costs over the life time of a machine. Reliability and high efficiency results in minimum downtime and loss of production. The failure of a corona treater system can result in a total plant shutdown costing far more than the difference in price between a low quality and higher quality treatment system.

Request for a quoteBenefit from our experience and also our innovations that we have developed on the basis of over 30 years of the closest collaboration with customers. To make your investment as safe as possible, we particularly concentrate on reliability in the form of-cutting edge technology. Systems for smooth, continuous operation. What costs the most money is not the investment you make in a new AFS system but the cost of shutting down your production facility. Stainless steel, aluminium and ceramics only. AFS' design and construction concept does not involve plastic in systems. This results in extremely robust machines which have a long service life. All of the components are readily accessible and the system is optimally adapted to your application. Should you require any assistance, our global service team is ready to help with expert and straightforward advice. Guaranteed. AFS offers more than the legally required warranty and its warranty cover two entire years.

- No downtime during job change - Easily quantifiable return of investment. - Waste reduction - Cleaning work can be done during operation safely and easily - Simultaneous grounding of the inactive electrode(s) - Segments with scale

Manufacturer/ Producer

Von-Holzapfel-Strasse 10

86497 Horgau - Germany

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam PC atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam PC is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 1440 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 1440 litres of this plasma system offers enough space to serve series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

FÖHRENBACH GMBH

Germany

The machine structure with solid base plate is extremely compact and stable. All necessary components are integrated in the machine housing: mechanical axes, pneumatic components, control with drive electronics and mounted 12 "touch display. Depending on the desired version, the F-Décor 305 can produce surface patterns like circular grainings, côtes de Genève, engravings or decorative millings on mechanical watch parts. The machine guarantees high precision and high productivity. The F-Decor 305 is delivered ready for connection with either 1 or 2 working spindles.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 45 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 45 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quoteCreate one request and get multiple quotes form verified suppliers.