- europages

- >

- Magnets

- >

- ASSFALG GMBH

- >

- products

ASSFALG GMBH

Germany

Manufacturer/ Producer

ASSFALG GMBH

Germany

The universal drive machine can be used for all materials. A wide variety of tools makes the machine very flexible in your production. The UA 5 has a controllable speed between 600-4000 rpm. It is ideal for polishing and fine work in low speed ranges. The installed spindle locking makes it possible to replace the tool fast and easy. Advantages: Grinding, polishing, brushing and deburring of all common materials with only one machine. Flexible and mobile use with flexible shaft Infinitely variable speed regulation

Request for a quote

ASSFALG GMBH

Germany

The handy drill grinders are ideal for grinding HSS- and VHM spiral drills. HSS drills are ground with CBN grinding discs and VHM drills with diamond grinding discs. Through the adjustable point angle from 90-140° and the adjustable point thinning equipment, these models can be used universally for different drill types. Easy handling and their efficiency make this machine a real winner in the field of drill grinding. Approx. 0.3mm is removed during each grinding process. The double-bearing grinding equipment guarantees a precise finish. The EDG 213 covers a drill diameter range from 2-13mm and the EDG 1226 from 12-26mm. Advantages: Precise regrinding of HSS and VHM spiral drills Easy operation Compact construction Fast and easy grinding disc change Point angle adjustable from 90-140° Adjustable point angle mechanism Comprehensive delivery accessories

Request for a quote

ASSFALG GMBH

Germany

The Neutrix is a small, light-weight and portable electrode grinding machine which is able to centrically grind in longitudinal direction, providing reproducible quality cuts of tungsten electrodes. Electrode diameters from Ø1-4mm can be reground. Only 0.3mm is removed from the grinding electrode during each grinding process. A stand can be mounted for use in the workshop. The point angle can be set gradually from 15-180°. The grinding dust is collected in an integrated filter cassette. The speed can be regulated for an optimal grinding speed. A special collet can be used to grind tungsten electrodes with a length of up to 15mm. The diamond grinding disc can be used three times through an eccentric disc. The grinding process can be observed through a window. The grinding pressure should be used to prevent the electrodes from glowing and thereby avoid early wear to the diamond disc.

Request for a quote

ASSFALG GMBH

Germany

The automatic weld-chamfering machines from the ASO 930 series are for stationary and portable use in weld seam preparation. The attachment of large welded chamfers on the workpiece bottom edge up to a chamfer length of 74mm can be performed by the machine effortlessly without any thermal change to the material. V, X, K or Y seams can be prepared thanks to the gradual angle adjustment from 0° - 75°. The machines are very durable and show their strength in every material through their sturdy construction. Extremely high tool service life can be achieved with the low-speed chamfering. Sheet thickness started at 8mm can be processed. Smaller workpieces can be processed manually. Advantages: Easy to adjust to material thickness, chamfer angle and working height No thermal change to the material V-, X-, K-, I- or Y- seams possible Very long operating life and cutting performance Gradual feed adjustment depending on material from 0 - 1.

Request for a quote

ASSFALG GMBH

Germany

The automatic recess chamfering machine ASO 910 is for welded seam treatment of, for example, duplex steel. The recess chamfering or resetting of cladding is mastered excellently by the edge chamfering machine. The attachment of chamfers on the top edge of the workpiece is possible up to 65mm. Thanks to the gradual angle adjustment from 90° - 75°, clean transitions are created between two workpieces with different thicknesses. The machine is very durable and shows its’ strength in every material through their sturdy construction. Extremely high tool service life can be achieved with the low-speed chamfering. Sheet thickness started at 8mm can be processed. The front, top and/or bottom side can be processed in one step through a special shape chamfer. Cavities in the front can be chamfered using the disc groove cutter. Advantages: Easy to adjust to material thickness, chamfer angle and working height Cutter head can be set in Z and X-axis No thermal change to the material

Request for a quote

ASSFALG GMBH

Germany

The automatic weld chamfering machine ASO 920 is for portable use in weld seam preparation. The attachment of large welded chamfers on the workpiece upper edge up to a chamfer length of 90mm can be performed by the machine effortlessly without any thermal change to the material, because the heat dissipation occurs through the chip. V, X, K, U or Y seams can be prepared thanks to the gradual angle adjustment from 0° - 30°. The highlight here is the machining preparation of a tulip seam. The machine is very durable and shows its’ strength in every material through their sturdy construction. Extremely high tool service life can be achieved with the low-speed chamfering. Sheet thickness started at 8mm can be processed. Advantages: Easy to adjust to material thickness, chamfer angle and working height Cutter head can be set in Z and X-axis No change to material properties, through heat dissipation via chip V-, X-, K-, U- or Y- seams possible

Request for a quote

ASSFALG GMBH

Germany

BKE 550 is a table or permanent device for extremely fast, double-sided deburring of sheet parts from all metals (including stainless steel), up to approx. 5 mm sheet-metal thickness, in a single step. The BKE 550 sheet deburring machine is for the highest demands in effective, fast and safe deburring. The double-sided deburring of sheets is guaranteed through the machine construction with two finned grounding wheels, which are installed directly on motor shafts that run opposite. Smaller and handy workpieces can be placed and processed with a horizontal table. Large metal sheets and strips can also be deburred with a vertical table. Advantages: Deburring of sheets on both sides Sheet thickness 0-4mm Can be used for small sheets in horizontal operation and large sheets in vertical operation Flap wheels for steel or stainless steel with different grit sizes

Request for a quote

ASSFALG GMBH

Germany

AF 165 is a tabletop device for the lightning-fast and efficient removal burrs. Faceting and deburring machine with fixed angle of 45° and gradually set chamfer width for all metals. Its special area includes the removal of saw burrs and roughing burrs so that workpieces can be further processed and are safe to use. Fast, cost efficient edge grinding is achieved by durable flap disks, CBN- or diamond grinding wheels. Advantages: Can be used for steels, aluminium, brass, copper, plastics, from soft plastics to acrylic glass, wood and much more. For hardened steels CBN wheels For hard metals Diamond discs Uncomplicated tool change Easy operation

Request for a quote

ASSFALG GMBH

Germany

The KSM 125 and KSM 130 edge grinding machines are designed for deburring and edge cutting of small to big workpieces starting with a thickness of 2 mm. The chamfer is scrubbed and finished in one step with our two-zone grinding disc. The chamfer setting is made by opening / closing the prism. This is used effectively and efficiently through the axial adjustable corundum grinding disc. The KSM 125 has an integrated extraction socket for connection to an extraction system. A water cooler is installed in the KSM 130. The machines are equipped with hardened and polished guide rails. Hardened workpieces and HSS materials can be processed p to 5mmx45° in multiple steps. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machines can be installed on an undercarriage for flexible use in a workshop.

Request for a quote

ASSFALG GMBH

Germany

The small and compact edge processing machine with sliding carriage is designed for chamfering and grinding small to medium-sized workpieces starting with a thickness of 1 mm. The light aluminium casing, the wear-resistant and sanded guide rails, the speed regulation and the optionally available extraction sockets convince in every regard. The sliding carriage protects the workpiece surface of components that are sensitive to scratches. The workpiece is inserted in the V-prism from the sliding carriage. The processing is performed by pushing the sliding carriage with workpiece over the tool. The travel path is 210mm. The sliding carriage can be locked in place for longer components. Our variety of high-quality solid carbide chamfers provide for vibration-free, clean and constant chamfering quality depending on the material. A chamfer width of up to 4 mm is possible in NE metals and a chamfer width of up to 2mm in steel.

Request for a quoteManufacturer/ Producer

Buchstraße 149

73525 Schwäbisch Gmünd - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

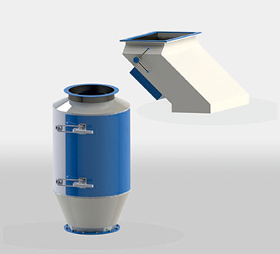

PARSMEGA MAKINA

Turkey

It is one of the auxiliary equipment that prevents metal and metallic parts from damaging the system by attracting them. Most of the machines working in Flour and Feed Factories rotate at high speeds. Screws and similar metal and metallic parts that break off during operation in the natural environment where the product comes from and in other machines enter our working machines and systems and cause damage. The magnet helps catch these pieces before they enter our machines and systems.

Request for a quote

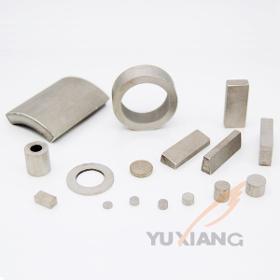

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

The characteristics of Samarium Cobalt Magnet •Very high magnetic properties with good stability •Superior resistance to high temperature, Curie temperature of majority is over 800°C •Excellent corrosion resistance capability, no coating is needed for surface protection

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free