BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Manufacturer/ Producer

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

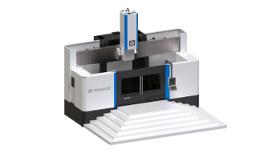

Machines of the T range are compact and ergonomically designed high performance bed type milling machines. They are characterized by optimum rigidity, mechanical stability, and high cutting capacity. The machine design guarantees optimum interaction between operator and machine. The areas of application include tool and mold making, mechanical engineering, and medium-sized precision parts in subcontracting. Longitudinal (X): 2,500 – 4,500 mm Vertical (Z): 1,500 – 1,600 mm Cross (Y): 1,200 – 1,500 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Machines of the S range are ergonomic milling machine with gigantic work area for long, large, bulky, and heavy workpieces. Modular system to meet individual customer requirements. Perfect for high-precision tool and mold making, mechanical engineering, and subcontracting. - Ideal for multi-station machining - Maximum precision for decades - Machine for large workpieces with power - New design for even greater ergonomics - User-friendly and innovative technology Longitudinal (X): 3,500 – 40,500 mm Vertical (Z): 1,800 mm Cross (Y): 1,300 – 1,500 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Multitasking machines for combined, precise milling, turning, and grinding of complex workpieces. Unique ergonomics and user-friendliness for optimum operation and work processes thanks to low machine table with integrated vertical rotary table and open access to the work area. Optimal machine concept for the production of single workpieces and series production. - Machining of complex workpieces in one clamping operation Longitudinal (X): 2,500 – 4,000 mm Vertical (Z): 1,250 – 1,800 mm Cross (Y): 1,200 – 1,500 mm NC-rotary table: Ø 1,250 – 2,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

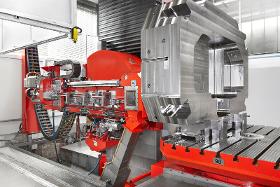

Floor type milling machines stand for flexibility, productivity, and maximum precision. All machines are hallmarked by optimum rigidity and dynamics and offer maximum productivity. The machine design guarantees optimum interaction between operator and machine. Areas of application include mechanical engineering, tool and mold making and contract manufacturing for machining large parts with heavy unit weights. - Machining of large parts in pendulum mode - Machine for large workpieces with precision Longitudinal (X): 3,000 mm – unlimited Vertical (Y): 1,800 – 8,000 mm Cross (Z): 1,300 – 1,900 mm Quill (W): 700 – 1,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

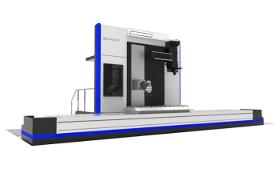

The SORALUCE KB-150-W series is a modern table-type horizontal boring machine for efficient multi-face machining of large and precision workpieces with weights of up to 40,000 kg. The heavy cast iron design and INA linear roller guide systems guarantee maximum stability and precision. The automatic milling head changing system provides exceptionally high flexibility thanks to the automatically lowering milling heads for machining at any angle. Longitudinal (X): 3,000 – 5,000 mm Vertical (Y): 2,600 – 3,200 mm Cross (Z): 2,000 – 5,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

The VTC series of vertical turning machines offer maximum stability for vertical turning, milling, drilling, and grinding. The basis of the VTC series is a sophisticated technology with a cast iron design paired with modern linear guiding systems. All machines are hallmarked by optimum damping, maximum productivity through high cutting capacity, and an ideal machine concept for machining highly complex and precision workpieces. The machine design guarantees optimum interaction between operator and machine. Areas of application: Mechanical engineering, gear manufacturing, new energy sectors, and high-precision subcontracting. Table diameters: 1,800 – 7,000 mm Turning diameter: 2,100 – 8,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

The portal and multitasking machines of the P series offer maximum precision and flexibility for machining large, complex and high-precision workpieces. Outstandingly suitable for machining prismatic and cubic workpieces in a single set-up and mounting position. An extremely heavy cast iron design with optimum damping properties and the INA linear guiding system equipped with hydro mechanical damping slides provide the basis for the ultra-modern table and gantry design portal machines. Areas of application: Mechanical engineering, new energy, tool and mold making industries, subcontracting sector and other industrial markets with very large, complex, and precision workpieces. - Table or gantry design with clamping tables of any size and NC rotary tables - Multitasking: Milling and turning on one machine Longitudinal (X): 3,000 mm - unlimited Vertical (Y): 1,500 – 3,000 mm Cross (Z): 4,000 – 10,500 mm Crossbeam (W): 1,000 – 4,000 mm

Request for a quoteManufacturer/ Producer

Am Steingraben 6

65549 Limburg - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

EMSIL TECHTRANS SRL

Romania

Gundrilling and milling centres for molds

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

High polish stainless steel flanges are not just functional components in piping systems; they also offer a visually appealing finish that is smooth and reflective. This high polish, often achieved through a process called electropolishing, provides several benefits: Electropolishing Process. Electropolishing is an electrochemical process that removes a thin layer of material from the stainless steel surface, resulting in a smooth and mirror-like finish. This process can also improve the corrosion resistance of the stainless steel by removing surface imperfections where corrosive agents could potentially take hold. Advantages of High Polish Finish Improved Corrosion Resistance: The smoother surface reduces the number of crevices where corrosion could start, thus enhancing the flange’s longevity. Easy Cleaning: High polish surfaces are easier to clean and sanitize, which is particularly beneficial in industries like food processing and pharmaceuticals.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling, can process a variety of materials,like Aluminum, Brass, copper,steel, Beonze, Steel Stainless .... Working length range:X:1-1066mm, Y:1-600mm,Z:1-600mm

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free