GSW SCHWABE AG - Sheet metal fans since 1963

Germany

Manufacturer/ Producer

GSW SCHWABE AG

Germany

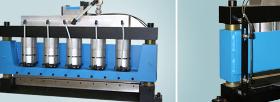

shock dampening for low operating noise levels thanks to a heavy overall frame and the sturdy, warpresistant design with heavy doublepost guides even toughest materials can be cut smoothly with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

GSW SCHWABE AG

Germany

Shock dampening for low operating noise levels Sturdy, warpresistant design with heavy doublepost guides With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control Mounting bracket

Request for a quote

GSW SCHWABE AG

Germany

Shock dampening for low operating noise levels Sturdy, warpresistant design with heavy doublepost guides With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control Mounting bracket

Request for a quote

GSW SCHWABE AG

Germany

With 2,5 degree cutting angle for clean, burrfree edges With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control

Request for a quote

GSW SCHWABE AG

Germany

GSW Shears find their place in CutToLength Lines or as Scrap Choppers. They are used to perform lasting and costefficient, no matter the roughness of the environment. Our pneumatic and hydraulic Shears are designed efficient in any way – and from 60 to 1500mm width The pneumatic machines run with up to 500 SPM while their heavy types are robust enough to lastingly process up to 3mm thick materials. Since they do not need hydraulic power or electric controls, they are extremely costefficient. If a combination of high SPM and thicker materials is necessary, our TSHL „light“ hydraulic Shears offer the solution. The TSHS series machines are built very heavy and stiff which allows them to cut up to 12mm thick materials. If yet larger widths than 1500mm are to be processed, we work together with most reliable German partners who supply us with highquality Shears in hydraulic, electric or servoelectric design. This way we can offer the very best suitable solution for any application.

Request for a quote

GSW SCHWABE AG

Germany

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Machine body in rigid steelplate design Cradle rollers of hardened steel, driven synchronously Clockspring guard Hydraulic threading system with prebending roller and peeler wedge Hydraulic hold down arm (optional w powered endwheel) Motorized coil guides Ultrasonic loop control Cradle rollers with separate threephase motor

Request for a quote

GSW SCHWABE AG

Germany

Coil Cradles are made to help unwind coils in rough production environments. Mostly combined with a straightening unit, they work with narrow and thick materials. Built to last, Coil Cradles offer quite a few advantages Simple handling of even hightensile materials with strong clockspring, short setup times, an elaborate coil handling concept which gives a chance to rewind of unfinished coils. By using serial straightening units, type RMA and RMZ, everything is well fitting. To achieve short mounting times and easy accessibility, the complete machine body features a one piece tiebar design machined with most modern CNC equipment. Coil Cradles, CradleStraighteners and CradleFeederStraighteners thus are very efficient too. Consequently, their compactness, efficiency, safety and operator friendliness melt into a coil handling solution which underlines GSW’s lead in technology. Performance data Up to 8 t coil weight, 700 mm stock width and up to 13mm thickness

Request for a quote

GSW SCHWABE AG

Germany

High feeding accuracy, quick cycles and simple operation Servo feeding in compact design with maintenancefree AC servo motor Fits just about any press +/ 0,025 mm feeding accuracy through incremental servo encoder Lightweight rollers with special hard chrome layer Mechanical pilot release Sturdy steel plate bolton design Height adjustment via threaded spindle Catenary rolls and edge guides at machine entrance Stock guides at exit Highperformance control with good functionality; with remote control for setup on 3,5 m cablel 24 V DC proximity switch adjustable piloting lever to be mounted to press pneumatic pilot release

Request for a quote