ITALGEAR SRL

Italy

Manufacturer/ Producer

ITALGEAR SRL

Italy

Cylindrical ground gears are cut by hobbing machines of the latest generation and finished by Reischauer and Gleason CNC grinding machines equipped with automatic loaders and special software that allow the correction of the twisting errors that may occur in helical gear and, with special ground cycles strategy minimizing noise of gears in operation. ITALGEAR can also make the finishing of the gears after carburizing heat treatment adopting the Skiving technology, which allows the precise finishing of gears through superfinishing of the teeth with a hard metal PVD coated hobs. The technology allows production of groundquality precise gears while reducing cutting time and costs effective at the same time. On request, ITALGEAR engineers can team up with the Customer R&D and suggest any appropriate measures to optimize the gear meshing in order to obtain low noise in operation.

Request for a quote

ITALGEAR SRL

Italy

The machining cycle developed by ITALGEAR for cylindrical shaved gears allow compensating, through appropriate correction of each single machining steps, the unavoidable distortions introduced by the carburizing and hardening heat treatment and obtain finished gears of the highest quality. Latest generation gear hobbing machines, combined with modern CNC shaving machines, all equipped with loading systems, allow for consistent quality and repeatability of the production process, besides excellent cost effectiveness. Shaved gears thus can be used in numerous applications such as automotive, industrial engines, mechanical drives, automated machinery, marine gearboxes, gearboxes, etc.

Request for a quote

ITALGEAR SRL

Italy

The common roots shared with the Poppi Forging Industries provide ITALGEAR a facilitated access to the forging facilities of the Group and particularly the ability to source electrical upsetted parts with dimensions that are predetermined by specific software’s that allow minimizing the stock material hence resulting into superior quality and price effectiveness of the finished product. Gears of shafts and axle shafts, after their heat treatment, can also be finished with the use of the Skiving technology that makes use of specific hard metal hobbing tools that are PVD coated. The Skiving technology allows production of gears that combine a high quality finishing with reduced machining time and costs.

Request for a quote

ITALGEAR SRL

Italy

ITALGEAR has long promoted grounding as the most effective gear finishing for Gleason bevel helical gears and takes pride in using the latest gear grinding machine from Gleason and Klingelnberg Oerlikon. The Tooth Contact Anlalisys (TCA) to obtain the optimal motion graph curves of the bevel helical gear that will generate the lowest noise and the highest precision once in operation is developed by ITALGEAR engineers through the use of specific software like CAGE and Kimos. Quality controls are performed by software’s like GAGE and Komet throughout the entire process in order to replicate precisely the mathematical model of the tooth profile.

Request for a quote

ITALGEAR SRL

Italy

High quality lapped Gleason gears that exceed the expectations of the most demanding customers are well within the capability of ITALGEAR who will implement their long developed experience in the field and develop the most effective Tooth Contact Area and motion curves of the bevel gear resulting into high precision and low noise in operation. Specific software such as CAGE and Kimos are used as well as strict controls of all the production steps are applied in order to replicate precisely the mathematical model of the tooth profile (software such as GAGE and Komet are used). The use of modern Gleason Phoenix CNC gear cutting machines and Klingelnberg and Remaut CNC lapping machines with a 100% gear final check in combination with vibration analysis, allow to obtain highquality lapped Gleason gears that will satisfy the most demanding customers

Request for a quote

ITALGEAR SRL

Italy

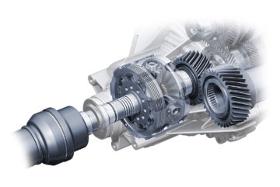

Over the years ITALGEAR has gained an extensive experience in the field of industrial gearboxes and complex transmission drives, collaborating, when requested, with the Customer for the optimization of the gears and their kinematics. ITALGEAR’s competence extends both to the production of gears and geared shafts, and to the complete assembly of the entire transmission unit. The production process is fully traced, including control activities, in order to guarantee the conformity of the finished product. Speed reducer manufacturers can therefore exploit ITALGEAR’s technical resources to outsource their production, in whole or in part, and thus rely on a specialized and skilled supplier when market conditions suggest flexibility.

Request for a quoteManufacturer/ Producer

VIA GIUSEPPE PARINI 18

40033 Casalecchio Di Reno - Italy