KLN ULTRASCHALL AG

Germany

Manufacturer/ Producer

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

Request for a quote

KLN ULTRASCHALL AG

Germany

One of the advantages which distinguishes the thermal riveting procedure from other assembly techniques is the safe form-fit. Another advantage: the thermoplastic cannot embrittle as in the case of ultrasonic welding. Apart from the well-established welding techniques for plastic parts in series, KLN Ultraschall AG also develops and produces in Heppenheim equipment for thermal riveting. This technique is still regarded as a very special procedure and has important advantages in comparison with ultrasonic, hot plate, vibration or spin welding. Thus it can be interesting for additional fields of application. This procedure is particularly applied for plastic parts having safety features. In contrast to the ultrasonic riveting, the thermal riveting can be applied without any problems for plate/ plastic assemblies, as no swinging tools are touching the plates which could endanger the assembly.

Request for a quote

KLN ULTRASCHALL AG

Germany

Our skilled service team is at your disposal for questions about our products as well as technical problems. Our services: • maintenance of all KLN-machines • training • cost-free Hotline (the service is free of charge, only the standard telephone costs will be charged. • augmented support • annual examination of BWS (contactless active protective device) • examination according to DGUV V3 • spare parts • repair center • repair offers free of charge • determination of adaption values of generators (cleaning sector) with special measuring devices • lifelong service installation files of all KLN machines The best day for good service is today!

Request for a quote

KLN ULTRASCHALL AG

Germany

With this machine system KLN has created a reasonably priced solution for aqueous part cleaning. Application is possible in all ranges of industry and for all kinds of contamination. The components can be compiled for any process in a modular construction system. They can be supplemented by all systems for tank care as well by an automation of the cleaning processes. The complete PWA series is available also in special sizes. The PWA cleaning tanks are available for determination of residual contamination.

Request for a quote

KLN ULTRASCHALL AG

Germany

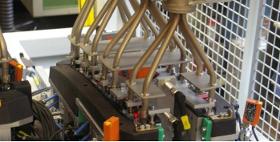

For the assembly of plastic parts, which differ in size and condition and would therefore not be suitable for standard machines, we recommend the use of special equipment with several ultrasonic units for ultrasonic welding and processing methods. • Riveting • Welding • spot welding • punching • flanging • cutting • embossing • printing Multi-head systems These machines can also be used to accomplish complex tasks, e.g. the combination of different welding techniques, like spin welding and hotplate welding and for numerous automated processes

Request for a quote

KLN ULTRASCHALL AG

Germany

The LVW series covers smaller applications with machines of approx. 500 mm width and large applications up to a width of 2000 mm, like pallets, bumpers and more. As a principle our standard machines are equipped with an hydraulic lifting table. Depending on the machine size a contact force of up to 70 kN can be applied. This is necessary for large suction pipes made of PA 6.6 GV30 with heavy distortion or very large welding surfaces. Our vibration welders are fitted with our patented CPC system. This kind of regulation which is integrated in the converter stimulates the vibration unit with optimal resonance frequency. A low energy consumption is guaranteed during the friction phase. It is not necessary to enter the frequency parameter in the machine, as it is permanently “optimized”. This, the KLN drive systems are independent from the tool weight. The tool weight is solely limited in height, caused by the mechanical design and the high accelerating powers arising in these systems.

Request for a quote

KLN ULTRASCHALL AG

Germany

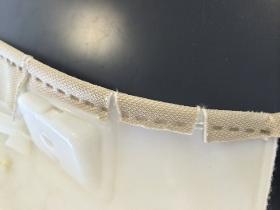

Based on a long tradition of ultrasonic processing KLN Ultraschall AG also today develops and builds edge-welding machines for textile back injection molded parts. Here in very complex fixtures the textile overlap is put around the part and fixed by means of special sliding technology. This is a highly complex task and requires sound experience in construction and optimisation of the assembly. Here the important know-how is the tool design and not the machine technology. After “edge folding” the stretched textile overlap is permanently bonded with the plastic by means of ultrasonic technology or permanently heated elements on the back of the plastic part.

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN ultrasonic generators are incorporated in cleaning tanks of various capacity from some liters up to several cubic meters. They have a high operating reliability also under extremely difficult application conditions. Based on decades of experience in developing ultrasonic generators today we have a broad variety of generator series, meeting the most various requirements concerning frequency, way of installation and output power.

Request for a quote

KLN ULTRASCHALL AG

Germany

We work with you to develop the best possible solution for your project based on standard systems or modular functional modules. We have developed solutions for welding, punching, riveting, drilling, wrapping, flanging, handling and many other processes. Your task is most important for us and our technicians will try find together with you a solution meeting the requirements in quality, cycle time and cost. Examples of special systems: • final processing machines for plastic fuel tanks • rotary table machines for vibration welding, infrared welding, ultrasonic welding and hot plate welding • edge-welding machines for textile back injection molded parts • ultrasonic or mechanical punching machines • infrared welding machines in modular design for welding of several parts in one go • fully automated operating cells e. g. with feeding technology and robot handling

Request for a quote

KLN ULTRASCHALL AG

Germany

The KLN BATCH-INLINE cleaning system is based on many years of experience with Inline Cleaning systems for the electronics production and unites, for the first time, the technological advantages of Inline cleaning with low space requirement of a Batch system. By far, most of the Inline cleaning systems in Germany for the large-scale production “Automotives” and “alternative energy” come from company KLN. This system was developed to make the efficient Inline cleaning technology available now also for customers with smaller budgets and throughputs.

Request for a quoteManufacturer/ Producer

Odenwaldstraße 8

64646 Heppenheim - Germany

europages also recommends

A selection of companies related to the activity:

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free