KLÖPPER-THERM GMBH & CO. KG

Germany

Manufacturer/ Producer

KLÖPPER-THERM GMBH & CO. KG

Germany

Whether it’s for maintaining stable temperatures in storage tanks, compensating of heat loss in supply pipes, liquefying firm substances such as wax or vaporizing water or thermal oils, electrical heaters by Klöpper Therm are the answer. Our heaters provide optimised, energy efficient and reliable process control for all kinds of plants – chemical, petrochemical and pharmaceutical – as well as power plants and refineries. Based on the client’s specifications, we verify the technical feasibility for each application and transforms it into a concrete design.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Heating of all kinds of liquids and gases, especially suitable for installation in hazardous areas (ex. areas). Continuous heating by means of heat exchange between the tubular heating elements and the medium. We are experts in customizing process heaters always ensuring to deliver solutions which will be both technically and economically sound.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Klöpper Therm electric flow boilers are used for generating hot water in heating units for direct heating, storage operation or for Power to Heat systems. As an alternative to other energy types in new buildings or when converting central heating units, these boilers offer a universal range of applications radiator heating, floor heating, mixed systems or bivalent operation with other energy types. Depending on the relevant operating conditions of the energy supplier, the boilers are used for direct or storage heating by utilising free electric power during off peak times.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

The energy market called for technical solutions contributing to a mains stabilization and benefiting from the potential of favourable energy prices at the same time. The warm water boilers can be delivered in a power range from 35 kW up to 1.2 MW whereas the hot water boilers are available with a capacity of max. 10 MW. By means of parallel or series connection of several systems the power range can be extended optionally. The functional principle of warm and hot water boilers relies on the direct heating of flowing water via numerous resistance heating elements. For control purposes, they are summarized in groups which are either switched in steps or triggered infinitely variable via a thyristor power controller.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

The compact steam superheaters of type series PVN reach high steam temperatures even at low process pressure. Due to the compact design and control concept, they are characterised by short response times, high control precision, and high availability (existing redundancies). In many cases, our steam superheaters are designed as a "stand alone" system and provided completely assembled with all necessary safety devices and controls. The customer must only provide the process connection and the electrical connection.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

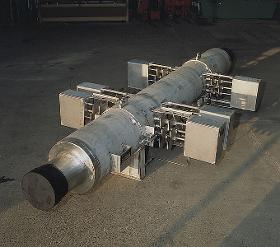

Cable Type Heaters have initially been developed and used for the safe operation in fertilizer plants. However nowadays, they cover a large range of applications due to their modular construction and minimum space requirements. They are suitable for heating up nearly all gases and liquids or superheating steam. They are mainly used in hazardous areas. Especially when processes require a combination of high power (in the MW range) high pressure and temperatures of up to 550°C cable type heaters are the means to choose.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

A drive motor can also act as a generator. If the drive system is built so as to allow reverse power to flow then this power can be fed into a resistor, thus taking energy out of the system and causing whatever is driving the motor to slow down. Following to this the braking resistor converts the stop energy into heat. Electrical drive systems are being used more and more on ships, oil rigs, crane barges and offshore vessels of all types. An important benefit from using an electric drive is that reliable systems of regenerative and dynamic braking resistors are available to complement or replace traditional mechanical braking systems. The advantages of electric braking include control, reliability, mechanical simplicity, weight saving and in some cases the opportunity to make use of the regenerated braking energy. The Braking Resistor Units from Klöpper Therm are designed according to specific applications.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Electrical heat tracing systems are used in all industrial sectors in order to heat up products in pipelines and vessels to maintain temperatures or to avoid freezing of the product. This type of heating offers several advantages It is highly flexible and adaptable to fulfil the specific customer requirements and ensures the effective and economic utilization of the input energy. Our customers appreciate the high accuracy of temperature control and the low maintenance costs. We offer harmonized components, engineering, delivery and installation from a single source.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

To maintain constant temperature in your tank or container, we provide the appropriate heating system. This could e.g. be implemented by heating the container surface with heating cables for holding temperatures of up to 250 °C. Transportable electrical heating equipment, including circulation pumps, are also available for holding temperature of up to 80 °C.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

For different, individual heating applications like reactors with highly specific heating capacities, for containers, diffusers, seal flaps, aluminium heating plates/blocks, inner tubular heating, foundation heating of cold tanks.

Request for a quoteManufacturer/ Producer

Unterste-Wilms-Strasse 21

44143 Dortmund - Germany