LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN - LIPP System - UNIQUE.WORLDWIDE

Germany

Manufacturer/ Producer

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Tank Refurbishing Quantities change and existing tanks become too small – these are also problems that frequently arise. In such cases, the mobile machine technology from Lipp using the LIPP® DoubleSeam System or the LIPP® welding technique offers a solution that is as simple as it is costeffective, while being extraordinarily stable. Tanks can be installed on site in any size required and can be placed in an existing steel or reinforced concrete basin using a mobile crane. The existing tank volume is utilised, eliminating the need for expensive demolition work. There is also a range of materials to choose from for the tank itself so that it can be optimally matched to the intended application. VERINOX®, the combination material developed by LIPP® consisting of galvanised steel (for the outside of steel containers) and stainless steel (for the inside of containers), is characterised in particular by the excellent costbenefit ratio that it offers.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Thanks to the Double Seam System, LIPP digesters have smooth internal walls (largely without any internal attachments) and ensure uniform mixing while keeping energy consumption low. The external panel heating guarantees uniform temperature distribution in the digester. These thermodynamic and mechanical benefits with LIPP digesters also mean that short retention times are achieved. The high functional safety, especially in respect of heating and stirring technology, promotes a low demand for process energy. Further benefits include minimal maintenance requirements and a long service life.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

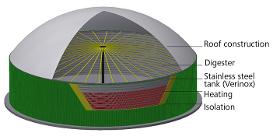

MUNICIPAL AND INDUSTRIAL APPLICATIONS WITH CHAMBER VOLUMES FROM 100 TO 7,000 M3 The LIPP UniCentralmix Digester with its central agitator is designed for industrial and municipal applications. The special feature of this tank, in addition to the central agitator, is the roof construction, with a high quality stainless steel diaphragm cover. The flexible LIPP System ensures each digester can be adapted to each individual application and customer requirements. KEY BENEFITS Energy efficient, central agitator Maximum leak tightness Flexible substrate composition High functional safety Stainless steel diaphragm roof without bolts External heating system available Production on site enables quick construction Low investment costs Low maintenance and durable High quality the world over PRODUCT SPECIFICATIONCENTRAL AGITATOR WITH BOLT LESS STAINLESS STEEL DIAPHRAGM ROOF At the heart of the LIPP UniCentralmix is a stainless steel tank (in Verinox) with a digester chamber

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. MAXIMUM LEAK TIGHTNESS AND PRACTICAL ON SITE CONSTRUCTION With Lipp digesters you will benefit from over 50 years experience in plant and tank construction.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

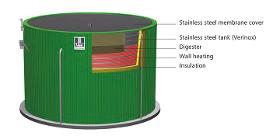

DIGESTER CHAMBER VOLUMES FROM 100 UP TO 10,000M³ The flexible LIPP Eco Digester for use in industry and agriculture can be adapted to individual requirements and customer demands. With a wide variety of different container roofs to choose from, tank solutions with or without an integrated gas accumulator can be offered. KEY BENEFITS Production of renewable energy and reduction of fossil CO2 emissions Low noise emissions Flexibility with regard to substrate composition Customisable pumping and stirring technology High functional safety External heating system available Production on site for quick construction Low investment costs Durable and low maintenance Consistent quality worldwide PRODUCT SPECIFICATION WIDE RANGE OF CONTAINER ROOFS WITH OR WITHOUT A GAS ACCUMULATOR The LIPP Eco Digester has a modular design and essentially consists of a stainless steel container (Verinox) with a digester chamber volume of 100 to 10,000 m3.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The range of material grades available and individually customisable pumping and stirring technologies provide optimum boundary conditions for any substrate composition. Pre or post treatment of the substrate can be carried out by installing additional tanks (e.g. hydrolysis, sugar beet silos and post digesters). With Lipp tanks for biogas plants which are built and used all over the world, you will benefit from 50 years of experience in plant and tank construction. They are constructed using VERINOX stainless steel which is characterised by maximum leak tightness and high quality. Stainless steel digester with a digester chamber volume of 100 to 10,000 m3 Wide range of tank roofs With or without optional gas accumulator Flexible stirring technology which can be adapted to the digester and substrate Smooth internal walls and uniform temperature distribution

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The smooth internal walls of the LIPP digesters (largely without any internal attachments) ensure gentle, uniform mixing while keeping energy consumption low. If an external heating system is fitted, it will guarantee uniform temperature distribution in the digester. These mechanical and thermodynamic benefits with LIPP digesters mean short retention times. The high functional safety, for heating and stirring technology, ensures a low demand for process energy and this is combined with the benefits of minimal maintenance requirements and a long service life.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The automated assembly technology in the LIPP Double Seam System enables the fast construction of stainless steel tanks which has a positive effect on investment costs. Efficient production on site, minimal installation space and a short construction time are key features of this flexible construction technology.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FLEXIBLE POST DIGESTERS FOR INCREASING BIOGAS YIELD LIPP offers three flexible Post Digesters for ensuring the effective utilisation of residual gases and improving efficiency which can be tailored to the requirements of each individual biogas plant. LIPP Universal Digester LIPP KomBio Reactor LIPP Eco Post DigesterCan be integrated in existing plants Flexible diameter and height Minimal installation space required Short installation time Durable tanks and covers Consistent quality worldwide Individually customisable based on customer’s requirements ROOFS AND COVERS PRODUCT SPECIFICATIONS LIPP POST DIGESTER THE RIGHT POST DIGESTER FOR ANY TASK The LIPP Universal Post Digester (with digester chamber volumes from 200 to 5,000 m3) comes with the high quality LIPP stainless steel diaphragm cover and is designed for use with an external gas accumulator. It is particularly suitable for the collection of residual gases and for improving efficiency.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel containers with digester chamber volumes from 100 to 10,000 m3 Gastight cover, with or without a gas accumulator Individually customisable Durable due to high quality materials Ideal for the collection of residual gases or for improving efficiency Homogenisation device to suit the task in each case Integrated gas accumulator with optional wind, weather and UV radiation protection

Request for a quoteManufacturer/ Producer

Industriestrasse 27

73497 Tannhausen - Germany