LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN - LIPP System - UNIQUE.WORLDWIDE

Germany

Manufacturer/ Producer

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

There is a variety of roof constructions that can be used to cover LIPP Post Digesters properly. The range includes foil roofs, single and double skin roofs and double diaphragm roofs as well as the high quality LIPP stainless steel diaphragm cover.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp offers liquid manure containers for farms of any size that not only make promises to provide safe and cost efficient storage but also keep those promises. Stainless steel may be the material of choice for constructing liquid manure containers but steel is expensive – and that is why Lipp uses Verinox, the material that it developed in house. A combination of galvanised steel sheet (for the outside of the container) and stainless steel sheet (for the inside of the container), Verinox offers all the benefits of a high quality material while enabling significant cost savings to be made at the same time. KEY BENEFITS Can be tailored to the customer’s requirements Steplessly variable in diameter and height On site production Construction without the need for container boarding or scaffolding Suitable for expansion High quality and a long service life Wide range of peripheral accessories Consistent quality worldwide

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The LIPP Double Seam System enables containers to be constructed on site within a short space of time with a diameter that is steplessly variable between 3 and more than 50 metres. Damaged concrete containers can also be easily refurbished (see Container Refurbishing). If a liquid manure container needs to be covered, Lipp offers a wide range of container roof and cover designs to choose from. The range includes simple foil roofs, single and double skin roofs and double diaphragm roofs as well as the high quality LIPP stainless steel diaphragm cover.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

COST EFFECTIVE SYSTEM FOR THE NON PRESSURISED STORAGE OF BIOGAS, LANDFILL GAS AND SEWAGE GAS In biological processes, gas production is not continuous. That is why the utilisation of gas (e.g. in a combined heat and power plant) requires an accumulator in order to compensate for fluctuations during gas production and to bridge downtimes for plant repairs and maintenance. Besides high functional and operating safety, other important criteria for the construction and operation of gas tanks include the economic aspects of investment and maintenance costs. DVGW approval held High functional and operating safety Highly accurate radar measurement enables exact content to be displayed Low investment and maintenance costs Quick construction Low maintenance Long service life Leak tightness can be checked

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp developed a system for the non pressurised (up to max. 5 mbar) storage of dry gas which has been used for over 300 projects worldwide over the past 30 years or more. Sizes from 30 to 5000 m³ are available according to the gas yield in each case. The gas accumulator consists of two parts a bubble shaped storage balloon a steel container to protect the balloon against mechanical damage and the effects of weathering The container is produced using the tried and tested LIPP Double Seam System. The storage balloon is made of polyester fabric specially laminated with PVC on both sides for improved gas resistance and UV protection. It is suspended in the container by means of a support ring. The gas pressure is increased as required between the gas accumulator and the point of utilisation by means of compressors. This results in lower investment and maintenance costs on the one hand and an extremely reliable and virtually wear free system on the other. Consequently

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

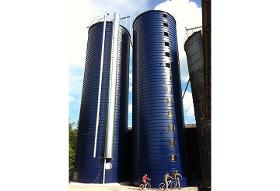

GUARANTEED OPTIMUM STORAGE FOR A WIDE VARIETY OF MATERIALS The storage of bulk materials needs to be not only cost effective but also safe, and systems should be easy to integrate in production processes. LIPP Double Seam technology and welded LIPP tanks have proven to be particularly suitable for bulk storage applications in industry and agriculture. LIPP silos provide a high level of stability and total leak tightness and protect bulk materials from moisture. The smooth internal walls of the silos are a benefit that pays dividends when storing special media. All kinds of bulk materials Grain Soya Silage fodder Woodchips Pellets Clinker brick Cement SILOS FOR STORING GRAIN AND OTHER FOODSTUFFS Grain, soya and other foodstuffs are precious commodities and a major asset in agriculture and they need to be stored particularly carefully. With the tried and tested Lipp Double Seam System, Lipp silos offer major benefits in terms of design and leak tightness.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

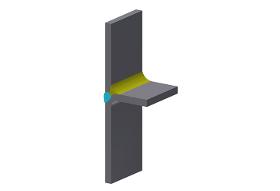

Containers are available in a wide range of sizes, with diameters of 3 m up to 40 m and volumes up to more than 10,000 m3. WIDE CHOICE OF MATERIALS There is a wide variety of materials to choose from, ranging from steel and galvanised steel through to high alloy stainless steels (e.g. 1.4301 [304] or 1.4571 [316Ti]), according to the requirements of the storage medium in each case. Developed in house, Verinox is a combination of galvanised steel for the outside and stainless steel for the inside of the container. Verinox is an impressive material due to its excellent cost/benefit ratio

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Efficient on site production enables silos with a variable diameter to be installed quickly and cost effectively at the customer’s site. ACCESSORIES Modules prefabricated at the factory, e.g. filling and draining systems, can be installed and added. THOUSANDS OF PROJECTS REALISED WORLDWIDE The tried and tested LIPP system has been used to construct thousands of systems all over the world for more than 55 years. In particular, customers value the longevity of the tank solutions and the possibility of easily modifying them or fitting a wide variety of accessories during their service life. A selection of the projects carried out using LIPP bulk storage containers is shown below

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quoteManufacturer/ Producer

Industriestrasse 27

73497 Tannhausen - Germany