METZNER MASCHINENBAU GMBH - Your Partner for Automation Solutions

Germany

Manufacturer/ Producer

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 10-SL" is a powerful and flexible press automation system for handling indexable inserts and small ceramic parts for medium to large batch sizes. It has an integrated magazine system for up to ten sintering inserts. Empty sintering inserts are automatically removed from the magazine, loaded and then returned as required. In this way, the powder press automation works independently over a longer period of time without loading and unloading processes leading to a press stop. With its integrated 4-axis SCARA robot, the machine achieves very high system speeds of up to 30 stroke/min. The "RPA 10-SL" is operated conveniently via the integrated control or via the mobile operator terminal. At the push of a button, loaded sintering plates are removed and new ones received. Defined operating data are transferred to the press control via an interface.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 60-LT" is a powerful robot press automation with an outstanding storage system for the highest demands in the handling of pressed parts made of hard metal and metal powder. With a storage capacity of up to 60 sintering plates, the it offers outstanding possibilities for the production of sintered parts of all types. All sintering plates are fed to the machine via four transport trolleys with 15 plates each. The intelligent handling system of the "RPA 60-LT" ensures uninterrupted loading of the pressed parts. While the first sintering plate is filled by a linear robot with multifunctional gripper, the handling system provides a second empty plate. As soon as the first plate is filled, the loading of the second one starts. Meanwhile, the handling system returns the loaded sintering plate to the transport carriage. The automation thus works according to the Kanban principle, which ensures that the press can be operated continuously even during the workpiece carrier change

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner offers low-cost individual stations in the field of e‑mobility for the entry into high-voltage cable processing. For the first time, the EM 101 module offers a solution for removing the cable foil without affecting the cable shield. The automatic processing of high-voltage cable wires also necessitates the connection of various components of the connector system. The Metzner EM 102 takes care of this. The EM 103 allows the cable shield to be opened and cut using a patented process which ensures that there is absolutely no contact with the inner insulation. The EM 103S offers the functionality of the proven EM 103 to meet the requirements of smaller cable wires of up to 8 mm diameter. These cost-effective models cannot be integrated into an automation line and are equipped with only limited traceability functions.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner EM 300 platform offers further convenience in high-voltage cable processing through a quick change of process tools and faster cycle times. Depending on the requirements, the HV cable processing machine can thus be equipped with different tools for cable processing. This means that the EM 300 can be used for several processing steps and is prepared for a wide range of processes. In addition, with the EM 300 we protect your investment by offering improved expandability that enables “plug-and-play” integration of future new applications.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The EM 600 can integrate up to six successive process tools in one single station. After insertion, the cable remains in a fixed position while the tools move towards the cable to provide optimum protection for the HV cable wires. The total cycle time of an EM 600 station is approx. 35 seconds for all operations of this station, with a total capacity of approx. 400,000 cable ends per year.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Multiple EM 600 stations in combination with a cost-effective transfer system provide the additional benefits of the EM 700 series: higher degree of automation, no limit to the number of stations, modular and scalable, single- or double-sided processing

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has a clear understanding of the future and transforms existing processes into fully automated system solutions. Workstations that were previously operated separately are now combined into fully automatic production lines. The starting point of an automatic processing line is the cable that is wound on a reel. The end result is a finished cable with a completely assembled plug system

Request for a quoteManufacturer/ Producer

Messerschmittstraße 30

89231 Neu-Ulm - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

CNC-STEP GMBH & CO. KG

Germany

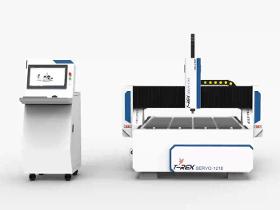

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free