- europages

- >

- Cleaning machines- industrial

- >

- PERO AG

- >

- Process Technology

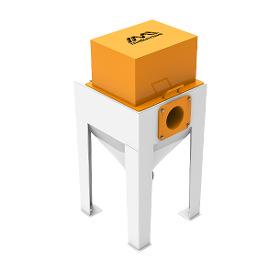

Process Technology

Description

Cleaning of machined parts (after turning, milling, drilling, etc.). Particularly suitable for the removal of graphite, AW and EP additives, salts, soaps, and emulsion residue. Generally suitable for the removal of dust, metal chips, surfactants, stearates and polishing paste. Preparation of parts for downstream processing such as joining (by clinching, etc.), assembly and packaging. Cleaning of machined parts (after turning, milling, drilling, etc.). Particularly suitable for the removal of grease, oil, wax, resins, corrosion protection agents and esters. Generally suitable for the removal of dust, metal chips, surfactants, stearates and polishing paste. Preparation of parts for downstream processing such as joining (by clinching, etc.), assembly and packaging. Cleaning of machined parts after turning, milling or drilling, grinding, polishing, lapping and honing, punching and forming (stamping & bending, deep drawing, extruding, etc.).

- Cleaning machines, industrial

- Cleaning Process

- Chamber Cleaning

- Cleaning Machined

Similar products

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to clean jet filter bags that lose their filtering function over time due to dust particles

Request for a quote

BRIO ULTRASONICS

Spain

Automatic ultrasonic cleaning equipment with a capacity of 150 L. Exclusive BRIO technology three times more efficient than conventional systems. PRO Series Automatic ultrasonic cleaning machines with premium features that optimise time and consumption. Automate your cleaning process and enjoy superior standard equipment with the most efficient ultrasonic cleaning system on the market. Lifter with loading grid for effortless handling of parts, tamping system to separate dirt, unique OPS oil decanting system, intuitive touch panel and much more. Robust construction with high thicknesses and AISI 304/316 stainless steel. Available from 150L to 7500L to cover all the needs of each sector.

Request for a quote

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

The part washing machine is designed to easily clean dirty parts with a small size and complex structure in the shortest time possible. Thanks to its brush, the person performing the washing process can carry out any kind of cleaning in the dirty part in detail. It is an ideal parts washing machine for using in small areas.

Request for a quote

EC PLAZA

South Korea

As the world’s global leader in semiconductor equipment manufacturing, VISION SEMICON has cease-lessly worked with the management philosophy of merging future-oriented technology with today’s technology in hopes of providing happiness and contentment for all humans. As the result, VISION SEMICON has received reviews from clients worldwide for its plasma treatment process equipment, which is the most important procedure in semiconductor production process, oven system and unmanned semiconductor production process.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free