- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aerospace materials

Results for

Aerospace materials - Import export

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer you stock and custom lambda/10 mirrors for use in government testing for aerospace, in a range of materials such as BK7 or equivalent, Zerodur, Quartz, UV Fused Silica and many more. Mirrors are made from low expansion glass for optimum stability to maintain the lambda/10 flatness. The mirrors help produce high quality images and can be coated with a variety of coatings to ensure that the perfect quality image in the wavelength you require is achieved: Enhanced aluminium 94%R for visible applications. 99.9% dielectric for laser use in visible applications. UV aluminium for UV applications down to 180nm. 98.5% dielectric for laser use in the NIR applications. Ion plated silver for NIR-2000nm applications. Protected gold for 750nm to far infra-red applications λ/10 mirrors are used in the aerospace environment due to the vibration, temperatures & pressure through which they are exposed. To Find out More read the PDF

Request for a quote

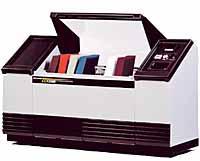

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Basic cyclic tests are used to qualify a coating or material for a specific end use on a pass-fail basis, or determine the probability of corrosion of a specific material. Applications include: Aerospace, Appliances, Automotive, Government, Marine Craft, Paints/Coatings, Research, and Telecommunications. Reinforced fiberglass cabinet, exposure lined with gel coat Solution reservoir - 35 gal (132L) Clear cover with dual magnetic Santoprene gasket (BCX9000 comes with opaque Polypropylene cover) Peaked cover prevents dripping of condensate onto sampl Exposure zone heated by titanium rod heater Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 131 °F (55 °C) - Hight temperature option up to 160 °F (71 °C) Omni-Fog Dispersion Tower or Omni-Fog II Dispersion System, fully adjustable. Built-in support ledges, front and back Wet Bottom Drain Assembly; heated, with auto fill for higher and more uniform humidity (n/a BCX11000) Air-assisted Cover Lifters on BCX9000 and BCX11000 Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) BCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 1.93 x 0.9 x 1.4 m BCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 2.46 x 0.9 x 1.4 m BCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 2.46 x 1.1 x 1.4 m BCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 2.69 x 1.32 x 2.16 m BCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 2.82 x 2.29 x 1.83 m Combination exhaust condenser and wet bottom drain assembly Recorder, 2-pen circular chart, digital display, 7 day, wet bulb and dry bulb Recorder, 6 channel strip chart; 4 temperature probes and air pressure Modem for remote trouble shooting Solution spray, two-nozzle External condensate collection package High voltage kit (over 460 VAC) Gas injection system for SO 2, CO 2, NO x High capacity oil & water extractor Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Air-actuated Cover; required for tests specifying ambient conditions Solution Spray; multiple nozzles (8, 12 or 16) with individual shut-off valves CE, UL CSA Conformance certifica High Temperature System, to operate BCX up to 71ºC / 160ºF BCX2000/BCX3000/BCX4000/BCX9000/BCX11000 SO 2 Injection; for customer-supplied SO2, customer-supplied fume hood recommended Data Recording Software; PC based, sends data to customer's computer

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia ceramic disc plates are characterized by high toughness, high bending strength, high hardness and high wear resistance.Zirconia ceramics have a dimensional hardness of 11.5GPa, a density of 6.0g/cm3 and a compressive strength of 2100MPa. Zirconia ceramics are widely used as ductile ceramics with fracture toughness up to 8.0 mpAM1/2. Advantages: smooth surface (easy to clean), good toughness, impact resistance, high hardness, wear resistance, low thermal conductivity (heat insulation), generally no insulation and high temperature resistance Applications: machinery, optical fiber, cutting tools, medical, food, chemical, aerospace Ceramic material composition: - - 95%--99.99% Alumina (Al2O3) - - Silicon Carbide · Silicon Nitride - - TTZ: Magnesia partially stabilized Zirconia (ZrO2) - - YTZP: Yttria partially stabilized Zirconia (ZrO2) - - ZDY: Yttria fully stabilized Zirconia (ZrO2)

Request for a quote

HAN SONG M&T

South Korea

[Product Description] S-PRO series is mainly used for cutting difficult-to-cut materials such as stainless, titanium, nickel and hastelloy in the aerospace field. A deep chip evacuation space of the S-PRO helps to cut difficult-to-cut materials, which facilitates chip evacuation and provides excellent surface finish. [Product Specification] Flat end mill : D1 ~ D20 Ball end mill : D3 ~ D20 C/R end mill : D1 ~ D20 [Product Model] Flat : 4SUE, 4SUEA Ball : 4SUB C/R : 4SUR, 4SURA [Product Use] * The cutting edge type of S pro series is unequal flute and it is suitable for cutting difficult to cut materials like alloly steels, stainless steels, Titianium, Inconel etc. * 4SURA, 4SUEA are specialized to cut Inconel. * Strong wear-resistance by adapting S-pro coating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DLR ELASTOMER ENGINEERING

United Kingdom

The margin for error in the aerospace industry is zero. Materials for applications in the sky, stratosphere & space are required to perform without fault. Rubber materials are proven to withstand the demanding stresses & temperature variations needed for the environment the products find service in. DLR designs the rubber compound, parts & tooling, enabling the products to maintain their properties when subjected to the extremes of the operating temperature range. The rubber can be formulated on-site to meet your specific physical properties & colour requirements.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has built a reputation for first class product quality and reliability, and that’s why so many leading commercial and defense aviation programs use our high performance materials. 50 years Aerospace Expertise We have more than 50 years experience developing precision strip, wire and shaped component products for critical aerospace applications worldwide. Our aerospace portfolio includes: High Tolerance Custom Shaped Wire for Aircraft Push-Pull Controls Pfinodal® (C72900) Bearing Material for Landing Gear Bushings and Bearing Sleeves Specialty Shaped Wire for Lock Collar Tape used in Aerospace Rivets Highly Conductive Nickel Strip for Aerospace Electronic Connectors, Batteries, Heat Exchangers and Bellows. Lighter and Stronger Materials for Aircraft Performance At 35,000 feet, every detail matters. We’re dedicated to manufacturing precision, lightweight and high strength materials to enhance the performance and efficiency of aircraft worldwide.

Request for a quote

BRAD-CHEM LTD

United Kingdom

Colloidal & non-colloidal Graphite or Molybdenum Disulphide stable dispersions in oil, water, or solvent. Can be used to add a solid lubricant extreme pressure additive to industrial engine oils, gear oils, chain lubricants, etc. Main uses include mould release, dye lubrication, forming & drawing lubricants, dry film lubricants, aerospace intrinsic lubricants, and refractory materials.

Request for a quote

IONITECH LTD.

Bulgaria

In the Hot-Wall type plasma nitriding installations, the heating of the parts in the vacuum chamber is done by both heaters and pulsed plasma. This type of installations are especially suitable for nitriding different shaped and sized parts in one batch. The main advantages of this type of equipment are: - The installations fully comply with the AEROSPACE MATERIAL SPECIFICATION; AMS 2759/8A; Can plasma nitride parts for the aerospace industries; Absolute temperature uniformity in all parts; The chambers could be equipped with their own lifting mechanism; No water cooling of the vacuum chamber;

Request for a quoteResults for

Aerospace materials - Import exportNumber of results

10 ProductsCompany type