- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing technology

Results for

Processing technology - Import export

SCHOCK GROUP

Germany

SCHOCK’s core competencies include roll forming technology with a large number of integrated processes. With our roll forming technology we are able to produce individual and high-precision profiles or complete assemblies for our customers.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Special cylinders developed and manufactured according to individual customer requirements, specifications or specifications. Both as a completely custom-made special cylinder or modified inexpensively using standard elements with adjustments in form, function, mount, connection or material.

Request for a quote

EC PLAZA

South Korea

EYL applies the natural process of radioisotope decay, commonly used in consumer medical devices, smoke detectors, and watches, to the use case of cryptographic information security. By exploiting the true randomness (entropy) of this quantum process, EYL's technology brings optimal security protection to a wide range of ICT and IoT products, at an affordable price. It's a game changer.

Request for a quote

ASTRA LT AB

Lithuania

Milk storage tanks Asepting tanks Yogurt production tanks Milk pasteurizes Equipment for curd cheese production Milk floats Milk accounting systems Technological process automation

Request for a quote

FRIMO GROUP GMBH

Germany

The right mix From basic to high-tech, FRIMO offers peripheral equipment for all PU processing technologies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

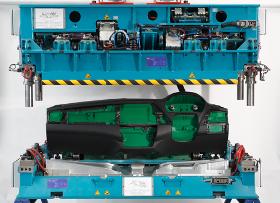

Ideal for trimming or scoring foils and skins FRIMO's scoring process technology was developed for producing hidden airbags in instrument panels. In contrast to composite component weakening in which the substrate, foam and skin are all weakened in one step, FRIMO prefers material specific single steps. The foil or skin is weakened by blade before foaming. The substrate and foam are separately weakened at the end, which can easily be integrated into the necessary component cutting process. Depending on the customer-specific requirements, this is where FRIMO punching machines or milling machines come into play. Compared to weakening entire composite components (for example, with a laser), a lower investment is required. For the weakening of leather parts for hidden airbags, FRIMO offers a patented process in which the skin is weakened by a rotating circular knife. This process guarantees high precision and odorless results with the shortest possible cycle times.

Request for a quote

FRIMO GROUP GMBH

Germany

Leading the market Leather laminating is found mainly in the automotive industry. High quality vehicle interiors are characterized by a sophisticated design made of perfectly processed and adapted materials. Leather surfaces are no longer exclusively reserved for premium vehicles; they are also becoming increasingly used in high volume and mid-priced vehicle interiors. As a natural material, leather presents tough processing challenges. Variations, quality/quantity requirements and numerous project-specific parameters demand smart manufacturing solutions that can only be produced with extensive experience and in-depth technology and process expertise. FRIMO's tooling and equipment technology in leather processing leads the market. Along with leather laminating come leather back-foaming and leather scoring for hidden airbags.

Request for a quote

SCHALLER MESSTECHNIK GMBH

Austria

The LF-TA transmitter of Schaller measurement instrumentation, with its robust and easy to mount aluminium housing, is best suited for all applications in this field. For temperatures of up to 60°C for laboratory, climate control and drying technology, wood processing industry, food and animal feed industry, building industry, printing and paper industry, agriculture, biotechnology and pharmaceutical industry.

Request for a quoteResults for

Processing technology - Import exportNumber of results

9 ProductsCompany type