- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- capping machines for packaging

Results for

Capping machines for packaging - Import export

CDA

France

The DS2000 stands as a standalone cap unscrewing machine, featuring an intuitive touchscreen interface. While it excels in autonomous operation, it seamlessly integrates into various CDA machines, including fillers like K-Net Auto and K-Line S, or complete packaging lines. Engineered to unscrew a diverse array of caps, the DS2000 finds applicability across multiple industries, including food, cosmetics, chemicals, and e-liquids. Its distinctive capabilities include the adjustment of motor speed, position, torque, acceleration, and deceleration, coupled with clamp movement. With a production rate of up to 1,500 products per hour, it offers versatility to accommodate different product shapes. To further augment its functionality, optional solutions for vial feeding and discharge are available, such as an independent rotative table.

Request for a quote

CDA

France

The DistriCap, an automatic module for dispensing twist-off caps (other formats subject to testing before project validation), is a creation of CDA. Engineered for automatic dispensing and placement of lids onto containers, the DistriCap seamlessly performs these operations "on the fly." This module seamlessly integrates with various machines, either after a CDA filler (such as K-Net Auto or K-Line S) or before an independent screwing machine (like VSA or VS1000). As a result, the DistriCap facilitates the dispensing of a cap or lid before being screwed and/or capped by a screwing module. Depending on the cap type, the machine can have two configurations: Lift/sorter/cap dispenser, typically used for twist-off formats. The lift, a vertical conveyor, sorts capsules by gravity onto a drop-off ramp. Vibrating bowl, commonly employed for plastic lids. The bowl directs caps directly to the appropriate side of the ramp.

Request for a quote

CDA

France

The VS 2000, an automatic screwing machine crafted by CDA, excels at automatically orienting and feeding caps onto containers before securely screwing them. Enclosed within a robust stainless steel frame with Securit glass, this screwing machine ensures durability and safety. Additionally, the VS 2000 can be configured with three sizes of stainless steel conveyors (82.5, 114, and 190mm chain) to suit various applications. This versatile machine accommodates a range of cap sizes, from Ø20 to 75mm. Depending on the cap type, such as grooved caps, smooth hinged caps, caps with integrated lids, childproof caps, etc., the VS 2000 can be equipped with the appropriate system. Ease of use is a highlight of this machine. A vibrating bowl efficiently feeds caps onto a multi-format conveyor belt, featuring a sensor to detect cap presence.

Request for a quote

CDA

France

The VS 1000 automatic capping module, a standalone capping machine crafted by CDA, is versatile and can be adapted to various cap types such as pump caps and spray caps. Designed to accommodate a diverse range of containers, spanning from 20 cl to 5 liters (encompassing vials, jars, bottles, etc.), the VS 1000 automatic capping machine is suitable for a wide spectrum of industries including food, cosmetics, chemicals, paint, cleaning products, and more. This automatic capping machine is equipped with a screwing system powered by two electric screwing machines, incorporating a detection cell to ensure cap presence and facilitating straightforward torque adjustment. Additionally, an optional pushing module can be seamlessly integrated directly onto the conveyor.

Request for a quote

CDA

France

The VST is an automatic module designed for the dispensing and pushing of headed caps. Crafted entirely from stainless steel, this linear machine is developed and produced by CDA. It efficiently dispenses T-shaped caps onto bottles and subsequently pushes them in. With a potential output of up to 1,800 corks per hour (dependent on cork type, etc.), the VST streamlines the capping process. Initially, the corks are placed in the cap lift hopper in a 'loose' manner. The lift then transfers the corks to an orientation bowl, ensuring they are correctly aligned. Subsequently, an automatic distribution mechanism on a ramp feeds the corks (oriented in the right direction) onto the bottle neck. Notably, the lift is a standard feature, enhancing autonomy and simplifying the operator's tasks. Specifically designed for T corks, commonly used in the food processing and distillery industries, the VST stands out for its adaptability and user-friendly operation and adjustment features, such as the

Request for a quote

CDA

France

The VSA stands as an independent capping machine featuring an intuitive touchscreen. While this capper can function autonomously, it also offers seamless integration into various CDA machines, including fillers (K-Net Auto, K-Line S), or comprehensive packaging lines. Multiple closing modules can be incorporated into this machine, including: The VS 400 (with tribological or lug screwing head), The VS 500 (featuring natural rubber screwing strips), The pusher (equipped with a stainless steel buffer), The crimper (designed for suitable crimping). The VSA allows for various closing configurations by combining up to two types of cappers, such as a VS400 with a pusher or a VS400 with a VS500. The choice depends on your project specifications and the cap requirements of your products. Manual placement of caps on the container before sealing is conducted by the operator.

Request for a quote

CDA

France

The VS500 electric screw capper stands out as a highly efficient automatic capping module featuring an integrated screwer, tailored for various cap types, including spray or pump caps. Its adaptability allows it to handle diverse formats effortlessly, and the crank height adjustment feature ensures optimal performance. Designed to seamlessly integrate into complete filling lines, this automatic screw capper enhances efficiency and productivity. Nevertheless, it can also function as a standalone machine, offering flexibility in its application beyond a comprehensive packaging system. With a 1000mm conveyor, the VS500 achieves speeds of up to 25 products per minute, contingent on specific format requirements, making it well-suited for a broad spectrum of production demands.

Request for a quote

CDA

France

The VS100 capping machine, crafted by CDA, is a semi-automatic, standalone screw-capping module designed for a variety of product caps. With an integrated screwer, this module efficiently screws caps onto your containers. It boasts user-friendly operation, featuring a two-hand control, and the adjustment of the screwing torque is facilitated directly on the screwing head. This semi-automatic capping system simplifies the screwing process for caps on diverse containers (semi-automatic screwing for bottles, vials, cans, etc.) catering to a broad spectrum of products: Food items (vinegar bottles, oil/olive oil, etc.), Cosmetics (soap, shampoo, etc.), E-liquids, Chemical products (detergent caps, etc.). For those in search of an automatic screw-capping machine, CDA provides options such as the VS 400 automatic capping machine (up to 20 products per minute, depending on the format) or the VS 1000 automatic screwing machine (up to 40 products per minute, depending on the format).

Request for a quote

CDA

France

CDA develops and produces the VS 50, a semi-automatic hand-held capper suitable for both smooth and grooved caps. The capping heads are individually crafted (based on the provided samples during the order) to ensure precise handling of the caps. Consequently, introducing a new cap may necessitate the fabrication of a new capping head. The VS 50 can function as a standalone machine but is also available with various options: Mounted on a stainless steel mast (to be directly affixed to a workbench or stable work surface). Mounted on a mast with a fixing nut (for lateral attachment to a conveyor or rigid work surface). Installed on a 500mm x 350mm shelf. Positioned on a stainless steel chassis with wheels. Compact and user-friendly, this manual capping device offers convenience in operation.

Request for a quote

PROXIO CO.LTD

Russia

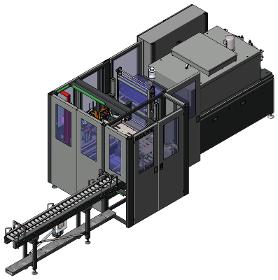

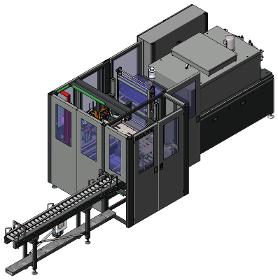

Design and construction of machines and complete plants for bottling, labelling, packaging of drinks and liquid foods in plastic, glass containers, machines for PET preforms, plasticl caps and plastic containers, pure pack, gabl top Automatic Machine Linear Type for Filling and Sealing FFS (Floumetric milk filling systems); Sinchrobloc WFS (Weight milk filling systems in Ultra Clean Edition) precise high performance systems; Rotary Type for Filling and Sealing machine (servo and mechanical drive) ; Complete line customized systems that include; Multi-packaging, palletizing Fully Automatic Sealing Machine for Containers; Servo driven fully automatic container filling, sealing and capping line. Available in 1-6 lines; Pneumatic fully automatic filling, sealing & capping machine. Available in 1, 2 or 4 lines; Servo driven fully automatic rotary filling & sealing machine; Mechanical drive fully automatic rotary filling & sealing machine; Packaging machines for mini bottles;

Request for a quote

PROXIO CO.LTD

Russia

By reviewing information about your business, we understand that there are room for collaboration-expanding your range of packing machines. We would be glad to offer you cooperation on packaging-bagging machines. We manufacture a wide range of packaging machines. More than 10.000 of our packers of various uses and capacities are in use worldwide. As a confirmation of our quality, we state that we have automatic packers that been in daily use (3 shifts more than 10 years). Production program: Automatic packers for : Powder Granular Pelleted Liquid (bottles) Gel Cream Honey Cristal-sugar Piece ( automotive industry, biscuit) Pebbles and gravel Semi-automatic packers for: Powder Granular Pelleted Cream Liquid Card-board equipment: Scoring Slotting Gluing Punching Printing Make in a single pass the correct form of corrugated cardboard boxes.

Request for a quote

PRO COUPE INDUSTRIES

France

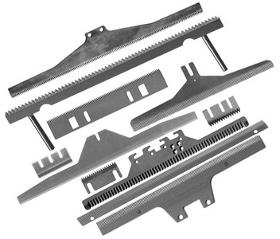

Thoothed blades for SIG® SANDIACRE® ROVEMA® FOREGROVE® PRASMATIC® OMORI® MULTIVAC® MIELE® MESOMA® MECAPACK® ILAPAK® HAYSSEN® COMMARME® BOSCH® AQUARIUS® TECNIMODERN® TETRA® TWINPACK® ULMA®

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-LC automatic spindle capper is almost a universal capper, it is sutiable for capping screw caps, flip flop caps, spray caps, drops caps, metal caps, twist off caps. An automatic spindle capping machine is a device used to cap containers with screw-on caps. The machine works by placing the containers under a series of rotating spindles, which spin the caps onto the bottles or jars. The spindles are adjustable to fit different sizes and shapes of containers, and the speed can be adjusted for different production rates. The machine may also include features such as a cap sorter and feeder, a conveyor system to move the containers through the process, and controls to ensure proper torque and alignment of the caps. Automatic spindle capping machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and efficient capping is necessary for product safety and quality.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Single head capping machine is speically designed to meet the requirements universal screw caps,for some manufacturers have different types of caps, and do not have a big bulk production. The bottles are going on inline on a conveyor, and for different size of bottles in a wide range which are not required changeover parts, and big difference diameter or size of caps, only replacing a capping head, the replacing time takes less than 2 mins. OEM factories prefer to such a bottle capper. The capping system is driven by a servo motor, torque is adjustable, meet almost all the users needs, for different height of containers, the capping head is adjustable.The whole capper was PLC control with HMI operation. for this capper is designed for OEM and low capacity need, so we considered more flexiable of the capper working and operation, meanwhile the cost is acceptable for most of the users.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The ROPP capper is the automatic capping machine which is designed to tighten pilfer proof cap for wine bottles, olive oil bottles, drinks bottles etc. It is suitable for φ12-55mm bottle caps (Equipment can be customized according to lid diameter). The automatic operation helps you save labor and reduce production error. The capping machine is a suitable equipment for roll-press-sealing the aluminum caps for the plastic bottle, pet bottle, as well as glass bottle. It processes the screw-press capping for the bottle under the rolling press from hobs, automatically feeding bottle, caps, removing the reverse caps. The capped bottle favors the characteristics like the stable capping effect, convenient uncapping, so that it function as conterfeit and anti-theft.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Press&snap capping machine is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc. The machine use the straight line into the bottle, automatically arrange caps, sleeving caps ,caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly.The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Fully Automatic Tracking Capping Machine Emotion Control is designed base on inline pick and place capping machine, it solve the low capacity of the inline pick and place capping machine, its movement is control by Motion Controller more efficient and accuracy than PLC, the capping heads are moving tracing with the bottles going when capping. it can be equipped with one or two capping heads, capacity is from 40b/m to 70b/m without thinking the size of the bottle and cap (base on 100ml to 5000ml bottle). This machine has the advantage of bottle non-stop working, so after the filling machine, even almost full of liquid inside, the liquid will not splash out when capping. It applies high efficient servo system, including the belt servo, horizontal moving servo, up and down moving servo, and servo capping head system Automatic gripping and capping are completed by the servo motor, and the movement is precise and the speed is fast.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERPLAST SNC

Italy

HOOD PACKAGING MACHINES - FP 5540 – FP 7060 SERIES L-seal hood shrink packaging machine combines sealing with shrinking into one step. The operator places the product between the two layers of mono-fold film, then moves the package into the sealing area and lowers the hood. When the shrink time is completed, the hood is returned to the up position and the operator may remove the completed package . The transparent cover makes the process of sealing & cutting and shrinking be visible. Colours: dark gray or orange depending on availability. It suitable for PVC shrink films with max. thickness 30 my and POF shrink films with max. thickness 19 my. Two models are available with a support surface of mm. 500x400x250h - mm. 650x550x300h. The dimensions of the support surface are to be considered with the hood closed. The volume cannot be completely filled by the box or by the product to be packaged as space must always be left for the passage of hot air around the product.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This coin feeder enables continuous feeding of a coin sorting machine or a coin wrapping machine. Fill level controlled by detectors. Adaptation to your coin trolleys. - Robust frame made of epoxy painted steel - Hooking device for all types of trolleys - Specially designed trolley that is easily handled and adaptable to the forklift truck - Possibility of manufacturing to your dimensions depending on the quantity required - Height adjustable from 500 to 1300 mm - Dimensions can be changed on request - Speed: up to 7000 pieces/min - Speed control by variator The materials comply with the applicable EC standards.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

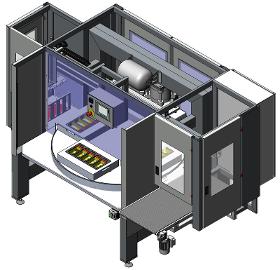

System for bundling coin rolls of 5 or 10 pieces and shrinking in PE film. Elements of serial production: - Robust steel frame, painted grey in RAL 9006 - Welding frame with Teflon-coated heating rods with constant temperature controlled by temperature controllers with digital display - Motorised unwinding of the coil - Control generated by a programmable logic controller - Touch screen display - Storage of programmes - Automatic change of designations - Detection of the end of the spool - Translucent housing - Material according to current EC standards Foils that can be used: Polyethylene

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Sleeve Wrapping Machines by Zappe – wrapping machines and shrink tunnels that adapt to your needs

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Zappe configures your blister machine to measure, regardless of whether it is a manual, fully automatic or semi automatic blister sealing machine.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Sleeve Wrapping Machines by Zappe – wrapping machines and shrink tunnels that adapt to your needs

Request for a quote

FINN-KORKKI OY

Finland

We offer spare parts for ring pull capping machines. A range of spare parts for 26mm and 42mm sealing head are available from stock. If you have any questions about spare parts, please feel free to contact us.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. Feature: 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduced wastage. 4. It completes the whole procedure of metering, filling, bagging, date printing, charging(exhausting), and counting automatically.

KALENDER MAKINA

Turkey

FULL MOTION CONTROLLED WET WIPES PRODUCTION LINE WITH TEN SERVOS AND TWO COILS Wet cleaning, towel (baby) wipes, etc. production can be made.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlled with fast and accurate servo driven specific auger (worm screw). The auger type and diameter Changes with respect to product type and target weight. All surfaces touching to products are AISI 304 stainless steel. · Sutiable for quadseal packages · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. · Printer state is checked continiously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. · Wrapping material tension is controlled continiously. · Auotamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

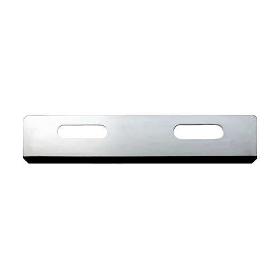

SOLLEX AB

Sweden

Ceramic coated injector blade in stainless steel for plastic film manufacturing. The fine structure enables the coating to protect the edge as long as possible. Ceramic coating is therefore advantageously used to cut white plastics. The injector blade with a thickness of 0.25 mm is a strong and small blade with high durability. For finer and thinner cuts, Sollex recommends ceramic coated industrial razor blade (2-013-K). Suitable for: White plastic film with a high percentage of chalk Dimensions: 38 x 8 x 0.25mm Grinding: Single edge Two sided Single bevel

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The weighing unit is controlled by a seperate microprocessor and touch screen.Supports many usefull functions such as multi dumping, automatic product conveyor control, self cleaning, recipe record for different products, different language and etc. Different amount of weighing buckets in different dimensions should be provided with respect to type of product. Parts touching to products are easy to dismount and cleaning. All surfaces touching to products are AISI 304 stainless steel. Sutiable for quadseal packages Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continously. Auotamic lateral adjustment of wrappin material.

Request for a quoteResults for

Capping machines for packaging - Import exportNumber of results

36 ProductsCompany type

Category

- Food industry packaging machinery (10)

- Hats and caps (8)

- Packing and packaging - machinery and equipment (3)

- Wrapping machines (3)

- Chemical industry - machinery and equipment (2)

- Chemicals and pharmaceuticals - packaging machinery (2)

- Custom packaging (2)

- Food packaging (2)

- Beverage industry - machinery and equipment (1)

- Industrial robots (1)

- Oils, cooking - machinery and equipment (1)

- Plastic packaging (1)

- Stoppers and caps, plastic (1)