- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sunflower seeds

Results for

Sunflower seeds - Import export

ANHUI HENNING SAINT TECHNOLOGY CO., LTD.

China

Henning Saint seed sorter can identify and remove black particles, moldy particles, pepper fragments and impurities from pepper seeds effectively. This color sorting machine is also suitable for sorting of vegetable seeds, fruit seeds, plant seeds and other materials.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The sunflower seeds dehuller is a product with completely independent intellectual property rights owned by our company, occupying 80% of the market share in the domestic shelling industry. This product uses an efficient shelling system and a professional separation system to achieve higher yields of finished products. This product uses a bucket elevator to transport the feed; the unique PLC electronic control system can control the equipment efficiently and conveniently, making the equipment more intelligent, user-friendly, and convenient. Product Features Reasonable structure and stable operation Large output and fast sorting speed Independent frequency converters for raw materials and recycled materials Low kernel loss Independent returning system Long maintenance cycle Low maintenance cost

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The KT5-3000 sunflower seeds dehuller is our patented product with exclusive proprietary rights and has a higher market share of 80% of market share in China. The highest perfect keel rate and maximum yield capacity of sunflower and black oil sunflower seeds are ensured by systematic shelling assembly. The production begins with raw materials being fed in the dehuller and the procedures. vertical transportation. and efficient separating sieves shelled materials. The mixture consisting of keels, husks, and unshelled seeds is discharged to a suspended separator. At this stage, a cyclone sucks and then moves hulls. followed by the separation of hulled keels and unhulled seeds with vibrating screens. The unshelled seeds will be returned to the dehuller. After passing all of the stages, the finished kernel is ready and deposited in the hopper. This product adopts a bucket elevator to transport raw materials, which can avoid blockages effectively.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

Based on years of experience in oilseed pressing and processing, Yongming machinery has designed two processes: cold pressing and hot pressing. The cold pressing process can retain active nutrients, reduce the color of crude oil, and produce oil with a strong flavor when using the hot pressing process to meet the needs of different users. Moreover, the oil yield is high and the production cost is low. The entire production line is equipped with advanced cleaning, pressing technology, and refining technology while paying attention to energy conservation and environmental protection, reducing emissions, saving costs, and maximizing corporate profits. Given the environmental protection and workshop hygiene requirements of modern industry, this production line is equipped with a complete dust removal system, and all connections for material transportation are equipped with suction to meet production and environmental protection requirements.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

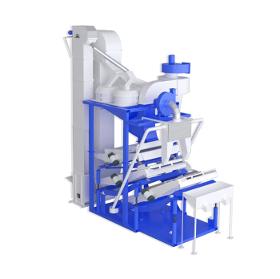

The KTF5-3000 Sunflower Seed Shelling Machine supporting equipment is composed of Wind-driven Elevator, Grain Impurity Screen and KTF5-3000 Sunflower Seed Shelling Machine. This supporting equipment is equivalent to a small shelling line, which has the functions of stone removal, dust removal, impurity removal, shelling, sieving kernel, etc. It has a short production process, flexible equipment placement. It can be used alone or in conjunction with a grinder, a finished product baler and a feeding auger. Only one person can complete the production of the entire small assembly line, which can effectively reduce labor costs.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Sunflower Seeds Shelling Production Line is a convenient processing line with high efficiency and less labor designed by our company for customers with large capacity requirements. It is a combined production line led by KTF5-3000 sunflower seeds shelling machine. The line is designed to confectionery sunflower seeds and remove the husk from the sunflower seeds before pressing the oil. The line processes oil sunflower, from which oil is then pressed. Description of the Line for Sunflower Dehulling (oil pressing): Intake and Cleaning: Sunflower is cleaned from larger and smaller impurities on Grain Impurity Screen Cleaner with an aspiration pre-cleaner. After cleaning, the sunflower is sorted. The Grain Grade Cleaner machine gains a dimensional spectrum of seeds suitable for dehulling. This is followed by destoning on a 125 MODEL DE-STONER.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sunflower seeds - Import exportNumber of results

6 ProductsCountries

Company type