- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coordinate measuring machine

Results for

Coordinate measuring machine - Import export

VISION ENGINEERING

United Kingdom

Deltron is a robust CNC CMM with compact footprint for high levels of measurement accuracy. Deltron CNC coordinate measuring machine, combines a compact footprint, with with substantial construction to ensure stability. This unique combination is only made possible by its delta mechanism incorporating carbon fibre rod construction, and well developed software control delivering high levels of measurement accuracy and repeatability. Smooth, fast operation. Deltron features fully sealed recirculating bearings, delivering four key benefits – no dirt ingress, no gearbox, no compressed air requirement and smooth, fast operation. Together these deliver exceptional accuracy, simplicity and reliability. Scale resolution of 0.1 μm and volumetric accuracy of (2.6+0.4L/100) μm combined with weight-saving carbon fibre arms deliver a high level of confidence in the measurement output – speed and accuracy you can rely on.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

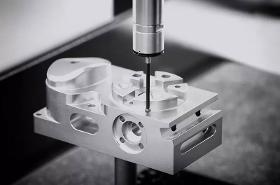

Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Specifications: Product name: precision machining parts Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity: 1000pcs Delivery: 7-30 days Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Custom Auto Shaft 1. All Custom Auto Shaft is produced according to your CAD and 3D drawings or sample. Please send the blueprint or drawing artwork first, and we will offer our quotation to you ASAP. 2. Materials: Copper, Brass, Phosphor bronze, Beryllium Copper, Aluminum, Stainless steel, Carbon steel, and Iron. 3. The surface finish of the Precision Stainless Steel Machining shaft includes: Electro-polishing, Electroless nickel plating, Silver plating, Golden plating, Zinc plating, TIN plating, Chrome plating, Bead Blasting, Phosphating, Turning, Heat treatment, Carburization, Case hardening, Sand blasting, Passivate, etc. 4. Testing facility: Coordinate measuring machine, projector, roughness tester, hardness tester, and concentricity tester. Height tester, 5. Part size: Diameter from 0.5mm to 150mm 6. Tolerance: +/-0.01mm, Or as your requirement 7. Lead time: 5-25 days after the confirmation of the sample.

Request for a quote

ZETEK SP. Z O.O.

Poland

GLOBAL EVO is one of the newest CMMs, which is characterized by high precision and accuracy. It is intended for measurements of details, in which the complexity of shapes makes manual control devices such as micrometers, altimeters, calipers impossible. It also replaces those gauges whose specifications contain very narrow tolerance fields. Measurement with an accuracy of 0.004 mm allows you to maintain stringent quality standards recognized by the largest automotive concerns in the world. CMM machines from the GLOBAL series also have large dimensions of the work table, thanks to which we can measure parts of larger dimensions. It should also be mentioned the increased efficiency thanks to which the measuring time can be reduced by up to 20% compared to other CMMs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZETEK SP. Z O.O.

Poland

The production of parts for machines and devices, the work of which requires very high precision and matching of each element, must undergo strict quality control. One of its elements is the dimensional compliance test, so important, for example, in the case of elements of bearings, gears or motors. Therefore, control and measurement instruments are an important part of the equipment of every company that carries out such serial production . These include, among others, coordinate machines with which CMM coordinate measurements are made . The precision of these machines' operation creates much greater possibilities than those offered by traditional control instruments - calipers, length gauges, micrometers, etc. The offer of the ZETEK company includes modern control and measuring instruments such as a coordinate measuring machine or a portable measuring arm. Thanks to its mobility, it allows you to take measurements anywhere, outside the laboratory or production hall

Request for a quote

PROGRES CNC

Poland

Coordinate Measuring Machine. Precise, dynamic and reliable. The LH is a universal and flexible instrument for different applications. The revolutionary design of the new LH offers high mechanical accuracy, perfect ergonomics and dynamics. The new generation of LH is equipped with an incremental measuring system, which has a fine grating period, and excellent dirt immunity. As a result best position resolution and stability at high speed for all linear axes are possible.

Request for a quote

ZETEK SP. Z O.O.

Poland

Serial production of details for the construction of cars, machines or household appliances is associated with the need to maintain a high level of dimensional precision. Especially in the case of machines and components in motion, their parts must be perfectly matched so that they interact without causing friction and accelerating the rate of wear. That is why systematic CMM measurements performed with the use of special coordinate measuring machines are so important. These machines are equipped with three measuring systems enabling simultaneous measurements in the XYZ coordinate axes. An additional element is a probe that allows you to locate the surface of the measured element. CMM coordinate measurementsthey take place automatically and are made with the use of CNC technology, also commonly used in precise CNC machining . Such production tests are characterized by very high accuracy and are not exposed to errors resulting from human physical limitations or his subjective approach

Request for a quote

SHINING 3D TECHNOLOGY GMBH

Germany

The DigiMetric photogrammetric system is a new type of 3D measurement equipment and known as a new generation of optical digital coordinate measuring machine, which is widely used in large and heavy equipment manufacturing industries such as automotive, aerospace, power generation equipment and engineering machinery, and has marked a new era in the field of largesize workpiece rapid 3D measurement technology.

Request for a quoteResults for

Coordinate measuring machine - Import exportNumber of results

11 ProductsCompany type