- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- trim

Results for

Trim - Import export

INTERLINEX B.V.

Netherlands

Tools reinforces with fiberglass Suitable for the disassembly for door panels, trim, rubber joints, instrument panels, switches and rearview mirror glasses.

Request for a quote

RHIMEX.COM

Netherlands

Edge profiles are suitable for finishing sharp edges or edges. They can also ensure a good seal by, for example, a bead or flap on the top or side. A firm clamping can be obtained due to an internal thin plastic or metal insert and the shape of the edge profile. No glue required due to the clamping effect Insertion in metal, plastic or stainless steel possible Perfect sealing or finishing of edges, doors, cabinets or machines

Request for a quote

MPM TEXTILES - HOTEL & HOUSEHOLD TEXTILES

Portugal

100% cotton bedspread Special finishings

Request for a quote

INTERLINEX B.V.

Netherlands

Tools reinforces with fiberglass Suitable for the disassembly for door panels, trim, rubber joints, instrument panels, switches and rearview mirror glasses.

Request for a quote

SEEDGE

Portugal

ROOTS Mix of flower cuttings Outdoor APPEARANCE Light Medium Green AROMA/FLAVOUR Fresh Natural Intense

Request for a quote

SHELDON INTERNATIONAL

United Kingdom

Baby Velour Bubble Wrap with Satin Trim Material: 100% Polyester Colours: White, Grey, Pink, Sky Size: 75x100 cm

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming or scoring foils and skins Blade cutting is a very fast, precise and clean process. In the automotive industry, it is particularly well suited for kiss cutting, edge cutting and for cutting notches in foils and leather skins to prepare for edge folding processes. A special form of blade cutting is scoring, i.e. the intentional weakening of leather, plastic foils and form skins to create specific tear lines, such as to allow the release of airbags. Ultrasonic cutting technology allows for even more possibilities in die and kiss cutting for foamed components with appropriate material combinations. This technology allows parts to be cut dust and chip free with a very low noise level.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming or scoring foils and skins FRIMO's scoring process technology was developed for producing hidden airbags in instrument panels. In contrast to composite component weakening in which the substrate, foam and skin are all weakened in one step, FRIMO prefers material specific single steps. The foil or skin is weakened by blade before foaming. The substrate and foam are separately weakened at the end, which can easily be integrated into the necessary component cutting process. Depending on the customer-specific requirements, this is where FRIMO punching machines or milling machines come into play. Compared to weakening entire composite components (for example, with a laser), a lower investment is required. For the weakening of leather parts for hidden airbags, FRIMO offers a patented process in which the skin is weakened by a rotating circular knife. This process guarantees high precision and odorless results with the shortest possible cycle times.

Request for a quote

FRIMO GROUP GMBH

Germany

Good ergonomics and optimal component accessibility Milling can be used to not only create highly complex component geometries, but also to achieve precise cutting depths. It is often used in combination with punching operations to produce component variations or small quantities, such as of instrument panels, center consoles or door panels. FRIMO FlexTrim milling machines have been specially developed to process complex 3-D plastic components. The newest generation of FlexTrim milling machines offers an attractive price/performance ratio. The new rotary table and product fixture concept ensures excellent ergonomic conditions for the operator and optimal component access for the milling robots. The use of multiple product fixtures per station reduces the number of necessary changes, thereby increasing productivity. Through the use of new milling technology with optimized chips, an effectiveness ratio of up to 95 % is possible with appropriate material combinations.

Request for a quote

PACKAGING TECHNICS & TRADE INTERNATIONAL

Netherlands

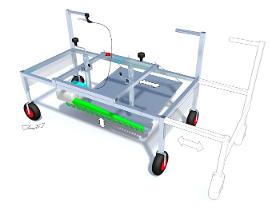

The EazyCut machines can be put in a special frame. 1200 or 1600 mm wide version. The frame can be extended and different wheels are an option. Height adjustment with spindles.

Request for a quote

PACKAGING TECHNICS & TRADE INTERNATIONAL

Netherlands

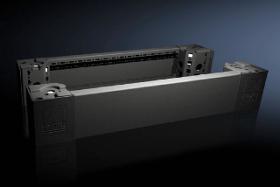

Venti machines work with a vacuumbox where all cuttings are collected undamaged. From 30 cm up to 200 cm wide for tables. Completely made of aluminium and galvanized steel.

Request for a quote

PACKAGING TECHNICS & TRADE INTERNATIONAL

Netherlands

The RAP 10 trimmer is a lightweight machine for the open field or pots. Round shapes of 15 up to 60 cm diameter can be trimmed. Also pyramid shapes up to 75 cm high are possible. Equipped with a Honda 4-stroke engine.

Request for a quote

RITTAL

Belgium

Base/plinth corner pieces with moulded self-positioning to the bayed enclosure system, for use with or without trim panels depending on the application. Large openings in the base/plinth corner piece for optimum access to the screw-fastening point may be concealed with a corner and baying cover. VX Base/plinth corner piece, with base/plinth trim panel, front and rear, H: 100 mm, for W: 600 mm, sheet steel

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Trim - Import exportNumber of results

17 ProductsCountries

Company type

Category