- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drum separator

Results for

Drum separator - Import export

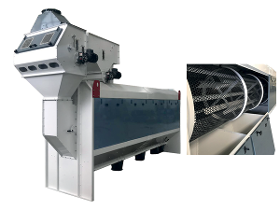

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The trieur separates broken grains and other foreign materials from the wheat. The wheat enters the drum and the foreign materials and broken grains are collected into the pockets located on the drum. These foreign materials are discharged by the screw conveyor located inside the drum.

Request for a quote

FEMIA INDUSTRIE

France

Washes most vegetables.Machine mainly made up of a washing tank, pumps that allow the creation of turbulent flows, a paddle turnstile to ensure the progression of floating vegetables and a lift belt. Recovery of water in a settling tank at the outlet of the washer and filtration of the water with a rotating wire drum and its scraper to separate the waste. Closed circuit water circulation for low water consumption. Depending on the products treated, a paddle turnstile can be replaced by an insect trap. As an option, a datura trap can be integrated into the washer.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

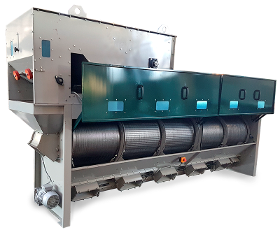

The OBC-355 universal grain cleaning separator is the most multifunctional drum-type machine for cleaning grain in the world. The number of operating options for the OBC-355 grain cleaning separator exceeds 50. The multifunctionality of the OBC-355 drum cleaner allows it to be used to separate and calibrate a wide range of products (for example: a mixture of any grain, grain with very high clogging, corn with very high humidity, cotton fibers and seeds, glass balls, etc.). The OBC-355 grain cleaning machine can be used both for high-quality calibration and for preliminary cleaning with large volumes of processing. Multifunctionality is achieved due to the innovative design of OBC-355, consisting of a large number of flap valves, screws and 2 main parts: an aspiration unit that removes light impurities depending on the air flow controlled by the regulation of aspiration; cleaning and calibration unit with a rotating drum that removes small and large impurities

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit. The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct. Grain separators OBC-355C have the following main advantages: Maximum versatility in application. Greater cleaning efficiency. High accuracy of grain calibration by aerodynamic properties, width and thickness. Minimal vibration during operation. Fast replacement of sieves. Gentle handling of seeds and grain. Adjustable performance. The presence of a cyclone that traps dust and light impurities. For more information about the advantages of OBC-355C, see the plant’s website.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IDEMAG

Spain

Eddy Current separation system consists of a conveyor belt and a rotor with a magnetic circuit built in 14 or 24 poles; to adapt to the grain-size distribution of the product. All within a steel case and covered by a counter drum . Being separates, the drum and the rotor inductor, allows operation at different frequencies. When the rotor turns at high speed it generates an electric current in the conductive metals (nonferrous), this inductive voltage produces a magnetic field opposite to the rotor, causing the non-ferrous metals being repelled. The rejected metal falls into the hopper by gravity, being separated from the other material. Eddy Current separators are indicated for the separation of non-ferrous metals: aluminum, brass, copper, etc., from inert materials. Used by recyclers in various sectors, production of semimanufactured and other processes. Separation of nonferrous metals in: car crushers, foundry slag, foundry sand, debris in domestic and industrial recycling companies

Request for a quote

EUROPEM

Belgium

Europem can supply complete flare systems which include knock-out vessels, water seals, molecular seals, conical purge gas seals, pilots and ignition systems. Additionally, Europem has developed a unique ATEX zone O vapour extraction system for use in conjunction with VRU’s, combustors, flares and thermal oxidisers. Vessels Europem supplies the upstream equipment to remove droplets from gases or provide a seal between the flare burner and the waste gas piping in order to prevent air from infiltrating the flare riser and thus prevent flash back. Purge gas is employed to prevent flash back by stopping air ingress to the flare gas header. Molecular seals and also Conical seals are both devices that reduce purge gas flow rates. Conical seals will require a slightly higher purge gas flow rate than a Molecular seal, but have the advantage of a simpler more economic design. This design cannot be blocked by debris, sludge or ice formation and does not put additional load on the flare structure, being integral to the flare riser. Although purge systems are the perfect solution for flash back prevention, the flow of purge gas can always be lost. A water seal can be installed to provide the ultimate barrier to flame propagation upstream in the waste gas piping. Vessels can be supplied either as an integral part of a flare system or as stand alone items. Both vertical, typically integrated with the Flare riser, or horizontal configurations are available. Features Water Seal Vessels equipped with an overflow weir to maintain a minimum water level, anti-pulsation baffles and a dip-pipe with distribution cone forcing the waste gas to flow through the water bath. Molecular Seals are equipped with a riser pipe and cap to either form a layer of purge gas on the top, when the purge gas is lighter than the air, or on the bottom when the purge gas is heavier than the air of the vessel Conical Seals are in fact an inverted conical restriction made as a section of the riser. This restriction will locally induce a higher waste gas velocity which in turn entrains any penetrating air and carries it up to the flare burner. Knock Out Drums contain packing to separate droplets from the waste gas. A liquid level control with automatic purging prevents the vessel from overfilling. Models EP-WS Water Seal Vessel EP-MPRS Molecular Purge Reduction Seal EP-CPRS Conical Purge Reduction Seal EP-KOD Knock-Out Drum

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The quality and consistency of flakes have a significant influence on board properties. Knife-ring flakers are flexible and can be individually adjusted to meet flaking requirements. The professional preparation of chips leads to the right flakes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator "Cleanomat" Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent flake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The quality and consistency of akes have a signicant inuence on board properties. Knife-ring akers are exible and can be individually adjusted to meet aking requirements. The professional preparation of chips leads to the right akes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent ake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The quality and consistency of flakes have a significant influence on board properties. Knife-ring flakers are flexible and can be individually adjusted to meet flaking requirements. The professional preparation of chips leads to the right flakes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator "Cleanomat" Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent flake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The quality and consistency of flakes have a significant influence on board properties. Knife-ring flakers are flexible and can be individually adjusted to meet flaking requirements. The professional preparation of chips leads to the right flakes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator "Cleanomat" Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent flake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The quality and consistency of flakes have a significant influence on board properties. Knife-ring flakers are flexible and can be individually adjusted to meet flaking requirements. The professional preparation of chips leads to the right flakes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator "Cleanomat" Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent flake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

UTF

Ukraine

Capacity: 1800 - 4200 pcs/h Number of rows: 3-7 Energy source: electricity Key features of the production line: - compact design - ability to work as part of a line or separately - replaceable cutting drums for different sizes of croissants

Request for a quoteResults for

Drum separator - Import exportNumber of results

14 ProductsCompany type