- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fine wires

Results for

Fine wires - Import export

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Automated control and manipulation of fine wire as small as 50AWG allows for twisting, cabling, reel-to-reel laser processing, and precisely ablated discreet lengths for applications that range from subcutaneous biometric sensors to implanted pacing leads and high-density wire harnesses for imaging catheters. High-density wire harness assembly is vertically integrated made possible through a combination of fine wire cabling and the dressing and termination of high-count cable to tight pitched circuitry.

Request for a quote

QUELLTECH GMBH

Germany

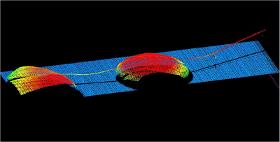

Testing requirements for a manufacturer in electronics industries had changed: For an assembly included in a smartphone, the absence of contact between speaker ultra fine wires and adjacent components is essential. Fulfillment of this condition, until now only subjected random sampling by microscopy, from now on has to be verified in a 100% procedure. Due to labor cost, microscopy for this amount of inspection is no more lucrative. Detection of ultra fine wires in electronic device The particular challenge The fine wires made of copper in smartphone speakers dispose of a high reflection and only a small diameter. The QuellTech Solution A high-resolution QuellTech 2D/3D Q4-5 Laser, featuring a particularly adapted laser wavelength and an ultrafine laser line in the corresponding installation, is combined with a linear axis equipped with a convenient encoder output. Due to its special chip analysis, the Quelltech sensor delivers a stable and highly reproducible signal on the fine wires

Request for a quote

STEEC

France

Spark erosion involves removing material from a conducting part and eroding it to give it the desired shapes and dimensions by means of electrical discharges. In the wire sparks erosion process an unwinding metal wire, under tension, is immersed in water or in another insulating liquid (dielectric) with the part to be worked. The current transmitted forms an electric arc which gives rise to precise, programmed degradation of a section of the part. The residues created by wearing of the part are removed by the water or dielectric liquid. STEEC carries out both spark erosion and fine wire micro spark erosion operations Wires spark erosion and machining Equipped with the latest wire spark erosion technologies, STEEC is able to carry high precision cutting with wires of standard sizes whose diameter may vary from 0.15 to 0.25 mm in all types of mechanical parts.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

Sheath color green-yellow for equipotential bonding and grounding. Flexible, fine-wire design.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). At PRUFREX, single-chamber and multi-chamber coils can also be achieved using two-wire windings. For specific magnetic flux requirements, we apply wires of different thicknesses to the coil form. Two different wire thicknesses, from 0.045 to 0.71 millimetres, on coil forms with press-in ferrite or metallic cores.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). To manufacture self-supporting coils, we use self-bonding wire. During winding, the surface of the wire is bonded using hot air. To ensure the coil connections can be soldered, they are then stripped of insulating enamel using a fully automated milling process. PRUFREX is able to make air core coils with wire thicknesses from 0.045 to 1.6 millimetres.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Fine Wire Strip Brush

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Fine Brass Wire Tube Brushes

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Fine Crimped Brass Wire Brushes

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Fine Brass Wire Tube Brush with Ferrule

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

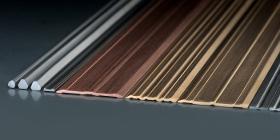

A specialist product made from crimped (wavy) stainless steel wire with a stainless steel backing strip and stainless steel retention wire. This product is available in 5mm, 8mm & 10mm stainless steel backing strip with filament lengths up to 250mm in fine stainless steel or 500mm in medium or coarse stainless steel. 3mtr lengths only. Aluminium or stainless steel holders are available.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Wire Strip Brush has multiple uses. From fine wire for polishing to coarse wire for abrading. We manufacture a large range of sizes and filament diameters to suit your application, many available from stock.

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Avicenna Technology is a leading provider of laser ablated fine wire and laser machine polymer tubing for the medical device market.

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

The ablation of fine wires by laser technology is a precise technique that involves the controlled removal of material from conductive wires, enabling numerous applications across various industries.

Request for a quote

JINTIAN COPPER

Germany

Main products: Electrical round copper wire Product characteristics: Bright and burr-free surface; superior performance quality; Can meet the technical requirements for drawing thin wires, fine wires and special products. Applications: Magnet wires, high and low voltage cables, electrical and electronic devices, communication technology, electrical network, mechanical hardware, construction industry Production capacity: 300,000 tons Honorary titles: Zhejiang Famous Brand Product

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Modern aircraft require dependable, high quality wire connection systems that play a crucial role in flight control performance to ensure safe transport of passengers and goods. Our high tolerance shaped wire is engineered for the production of push-pull mechanisms and custom cable assemblies used to deliver remote activation of aerospace controls. The shaped wire is used by manufacturers of these devices to build a bearing controlled linkage for applications requiring high tension and compression forces and tight radii for the wire cable assembly. Products We deliver custom wire shapes, custom alloys and precise sizes tailored to your specific push-pull control cable aircraft application. Alloys: Aluminum, carbon steel, copper, nickel alloy, nickel iron, resistance alloy, stainless steel, and other alloys such as nickel, iron and cobalt. Sizes: Super fine wire engineered from 0.004" (0.1016 mm) up to 0.250" (6.35 mm).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GARNTEC GMBH

Germany

Decoration Yarns made from paper - Creation in all colours! GarnTec Decoration-Yarns are suitable for tinkering or in the floristic due to the simple handling. Manufactured from paper and fine wires our yarns are pollution free and biologically degradable. Diameters of 0,8 mm with 0,4 mm wire or 1,5 mm with a wire inlay of 0,4 mm or 0,6 mm are available. The yarns will be supplied on coils with different length. Naturally we can supply cut length, multiple yarns, paper tapes and paper cords for decoration.

Request for a quote

METALLURGICAL SRO

Slovakia

- copper SG2 (G3Si1) wire designed for welding fine-grained steels with minimum yield strength up to 420 MPa, unalloyed structural steels with strength up to 530 MPa. - suitable for welding both fillet and butt welds in all positions. - welding is possible both in the atmosphere of mixed gases Ar / CO 2 and in pure CO 2 . - lower spatter and excellent operational properties.

Request for a quote

KUK COILS SLOVAKIA S.R.O.

Slovakia

In coil manufacturing, the production of miniature air coils or micro coils is one of KUK's specialities. According to your specific requirements, we process ultra-fine wires from a diameter of 0.010 mm, which are suitable for a wide range of innovative applications. Thanks to integrated plant and tool construction, KUK Group has the capabilities to process ultra-fine wire from 10 µm and to produce micro coils with diameters from 0.3 mm. For miniature coils with magnetic cores, cores made of a wide variety of materials are possible, including mu-metal, ferrite or amorphous materials. Custom coil solutions can be developed with guide configurations for manual assembly or surface mount SMD coils for delivery in tape and reel, allowing automated reflow processes for PCBA. Our micro coils can be wound with copper, silver, gold or other wire alloys. Various coatings, overmoulding, packaging and test options are available.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

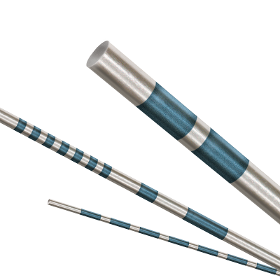

The line preheater guarantees successful and high-quality preheating of the conductor for the subsequent extrusion. This improves the adhesion of the cable insulation and the adhesion of the conductor. The preheater is suitable for use in extrusion lines for manufacturing of all types of cables. Properties Inductive heating technology Robust and durable design Material library for fast setup Integrated wire speed sensor that automatically compensates the power output Integrated PoE Ethernet interface Integrated web server in all processor versions Benefits Automated range selection with smart self-monitoring Actual input temperature for control circuit (analogue 0-10 V or serial RS) Optional fine wire guide for very small diameter ranges.

Request for a quote

KUK COILS SLOVAKIA S.R.O.

Slovakia

KUK manufactures air coils for a wide variety of applications, e.g. RFID antennas, control coils or transponder coils. To produce self-supporting coils, self-bonding wire is also used, which is superficially bonded (glued) together during or after winding. Air coils are usually made of enamelled copper wire or high-frequency litz wire. So-called self-bonding wire is used to manufacture self-supporting air coils. It has an outer layer whose melting point is lower than the melting point of the insulation. After winding the air core coil, the turns of the coil are "baked" (glued) together by heating, usually by increased current flow. Thanks to our in-house plant engineering, we can optimally align our production lines to your needs, even for air core coils. - Ultra-fine wires starting at 0.020 mm - Single-layer flat coils in cylindrical or rectangular shape - single, bifilar or trifilar winding - Winding with HF litz wires

Request for a quote

TELMAKSAN

Turkey

TELMAKSAN specialized in manufacturing aluminum and aluminum alloy wires in both medium and fine diameters. Telmaksan aluminum wire facility is recognized as the Europe's fastest, as well as leading manufacturer of bare aluminum wire and aluminum alloy wire products. Due to our flexible production system even requirements for smaller quantities can be accommodated with a short production lead time. The lightness, flexibility, excellent conductivity and resistance to corrosion make aluminum wire the ideal material for many different uses. Its production is aimed at technological improvement and quality control to achieve best results for its customers’ requirements.

Request for a quoteResults for

Fine wires - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Metal brushes (6)

- Electrical & Electronic Components (4)

- Coil winders (3)

- Coils and solenoids (2)

- Medical Equipment (2)

- Aluminium and aluminium alloys (1)

- Aluminium wires and cables (1)

- Copper wires and cables (1)

- Gardening and horticulture - equipment and supplies (1)

- Heating, industrial - installations and equipment (1)

- Lasers - medical applications (1)

- Steel & Metals (1)

- Steel, carbon (1)

- Tools & Hardware (1)

- Wires and cables - ferrous metal (1)