- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine maintenance

Results for

Machine maintenance - Import export

SANHA GMBH & CO. KG

Germany

Practical system push fittings with safe and innovative lock function from copper alloys for use in a system with SANHA MultiFit®-Flex and MultiFit®-PEX multi layer plastic tubes for hygienic drinking water and reliable heating installations. Due to their sophisticated construction, SANHA system push fittings offer an especially safe and durable connection and are just as tight as press fittings. The push connection is easy to make and has the distinct advantage that no tools are required. In this way, using 3fit®-Push fittings incurs no cost for buying, repairing or maintenance of press machines. 3fit®-Push system fittings are ideally suited in narrow spaces where it might be difficult to press fittings with jaws or slings such as during the renovation of buildings.

Request for a quote

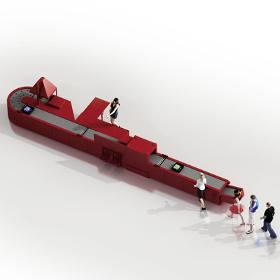

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Hand Baggage Control Unit conforms to the latest standard of technology and requires minimal staff involvement for handling. The defined field of use is automated hand baggage transportation into containers with automatic container return. This keeps the manual handling of the containers to a minimum. The security personnel can focus entirely on checking passengers and baggage. UltraSimple Adjustments Ultrasimple adjustment to required installation conditions with modular system Universal Compatibility Can be combined with all conventional XRay machines. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

HAVER NIAGARA GMBH

Germany

The NIAGARA® scalper is the best choice for crushing plants or the classification of coarse and difficult-to-screen materials at high throughput rates and fluctuating material feed rates. The unique NIAGARA® drive system generates a constant circular vibration motion at a fixed amplitude. The amplitude remains unchanged over time, no matter what the material load is. The application area of the NIAGARA® Scalper covers a variety of industries and materials with a length of up to 2000 mm and a cut size of 2 - 450 mm. Advantages reduced loads and energy demands for the subsequent crushing plant increased crusher capacity maximising the quality of the crushed product quick and easy re-balancing is always possible built with long-life bearings maintenance-friendly, modular machine design dynamically balanced construction modernisation of existing plants, performance improvement You’ll find detailed information in our product brochures and specification sheets.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Machine maintenance - Import exportNumber of results

3 ProductsCompany type