- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal cleaning

Results for

Metal cleaning - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

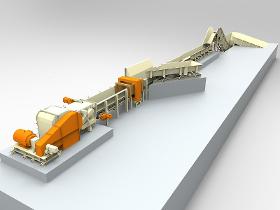

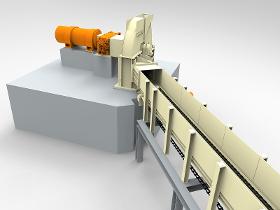

The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient drum chippers, the production of high-quality chips is guaranteed. Key features Simple feeding of wood directly from the truck Robust underground bins or vibrating feeders Vibrating conveyor lines Drum chipper Metal sensor and roller conveyor cleaning system Advantages Use of almost any type of wood material Continuous and uniform material feed Safe removal and discharging of rocks, sand, and other contaminants High lling level and high utilization of chipper capacity

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The plantation wood line is designed for processing uniform wooden logs grown in plantations. These logs have lengths between 3 and 8 meters and diameters between 100 and 450 mm: With the log feed, dosing step conveyor, debarker, washing system, dosing system all the way to the highly-ecient disc and drum chippers as well as the mills for the preparation of bark, the production of highquality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Dosing step conveyor for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Depending on the debarking demand, use of drum or rotor debarker Disk or drum chipper Advantages Robust, highly controllable wood feed Debarker adapted to the debarking demand Minimal ne material content High lling level and high utilization of chipper capacity High operational safety

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The long-wood line is designed for processing logs with lengths between 3 and 8 meters and diameters between 50 and 850 mm: With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient disc chippers, the production of high-quality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Buer capacity of up to 30 minutes/ 80 metric tons bone dry material Step feeder for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Rotor debarker for eective debarking even at extremely low winter temperatures Robust drum chipper Advantages Highly controllable wood feed Ecient debarking Perfect chip quality thanks to the adjustability of to the feed material mixture Minimal ne material content High lling level and high utilization of chipper c High operational safety

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

This is the ideal piece of equipment for blasting small and even smaller surfaces of glass and metal for matting, fettling, cleaning, polishing and drilling. All mineral media such as corundum, glass beads, cullet, silicium, walnut and plastic granules in the grain size range of 0 - 300 μ can be used as blasting agents. There is a selection of hard metal nozzles with a diameter of 0.8 mm and 1.0 - 1.2 mm as well as 1.5 mm for various requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Metal cleaning - Import exportNumber of results

6 ProductsCompany type