- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coupling flanges

Results for

Coupling flanges - Import export

GRÜNING & LOSKE GMBH

Germany

Short description: For clamp ring binding

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: For quick binding

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: For quick binding

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

RINGFEDER® Flange Couplings are the better alternative to press fits. Neither additional components such as keyways or wedges, nor a warming of the outer section and cooling of the inner section are required. The flange coupling is simply pushed onto the shaft and fastened so it is frictionally engaged by tightening the screws in the shrink disc. They transfer torque and bending moments as well as axial and radial forces. Advantages Strong connection with high torque capacity Easy assembly and disassembly Backlash-free shaft hub connection High level of true running accuracy Applications Mining companies Plant manufacturers Gearbox manufacturers Designs Version A Shrink Discs with hexagon head screws HM = Centering outside HF = Centering inside Version B Shrink Discs with hexagon socket head cap screws HM = Centering outside HF = Centering inside Explanations to tables Basic dimensions when screws are not tightened d w1 = Solid shaft diameter d w2 = Solid shaft diameter A =...

Request for a quote

IGUS® GMBH

Germany

The new direct-current motors with worm gear enable quiet and economically efficient operation with drylin® lead screw units. The worm wheel has a spline to which the drive pin of the linear unit is connected. As a result, a motor flange and coupling are unnecessary and, this taken in conjunction with the motor adapter angled by 90°, the structure of the linear module is very compact. Thanks to the integrated magnetic rotary encoder (2-channel hall), the new DC motors are suitable for positioning. - Space-saving and compact design - Easy to fit - Quiet operation - Rotary position encoder included - Suitable for: SLW-BB, SAW, ZLW

Request for a quote

R+L HYDRAULICS GMBH

Germany

Minimum mounting length Blind assembly No maintenance Heat resistant up to 120°C High torsional stiffness

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Advantages Salient features and advantages of the RCT coupling: ➜ Sub critical operation through high torsional stiffness ➜ Vibration and torque shock damping through flexible rubber coating ➜ High torque transmission capacity, fail-safe ➜ Ambient temperatures from -25 °C to +100 °C ➜ Compact, robust, maintenance-free ➜ Ease of assembly thanks to the plug-in axial design ➜ Backlash-free shaft-hub connection ➜ Compensation of axial, radial and angular displacements ➜ Multiple spline options for the connection to the pump shaft ➜ Bellhousing flanges for almost any mounting situation

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

Versatile, highly flexible handling hose for use in zero-pressure applications. For suction and pressure purposes with additional rings. Compressible to approx. 30% of original length. Robust version to handle solid media in the most cramped installation conditions. Outstanding axial and lateral movement. For information on temperature and media resistances please see our Simon resistances chart. Construction: Tube in special quality depending on the medium to be handled Tension and pressure-resistant special fabric inlays Optional: Concealed spring steel wire rings UV, ozone und weather-resistant cover Interior and exterior corrugated Couplings or flanges at both ends In fixed lengths with cuffed ends and/or widened hose endings. Other versions and dimensions on request.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

We can supply you with highly wear-resistant stainless steel pipe bends which have a service life 10 to 20 times longer than that of standard stainless steel pipe bends. This high degree of wear protection is required, for example for conveying fibreglass-reinforced plastic granules or similarly abrasive media. suitable for use of highly abrasive products easy installation no stepped pipe couplings and no flange connections required safe for use with food

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRS – Geared agitator with helical geared drive The GRS geared agitator is equipped with a helical geared drive suited for a wide range of applications thanks to shaft lengths of up to 2,000 mm and drive ratings of up to 7.5 kW. The GRS series agitators have a standard output speed of 10 to 500 rpm. The shaft mounting options available include sleeve coupling, flange coupling, quick-change coupling or precision-change coupling. The agitator shafts are balanced for concentric run after assembly of the mixer. Upon request, we supply the GRS series with frequency controlled drive. Depending on the specific mixing task, the GRS can be supplied with matching mixing elements and various seals. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRS geared agitator is equipped with a helical geared drive suited for a wide range of applications thanks to shaft lengths of up to 2,000 mm and drive ratings of up to 7.5 kW. The GRS series agitators have a standard output speed of 10 to 500 rpm. The shaft mounting options available include sleeve coupling, flange coupling, quick-change coupling or precision-change coupling. The agitator shafts are balanced for concentric run after assembly of the mixer. Upon request, we supply the GRS series with frequency controlled drive. Depending on the specific mixing task, the GRS can be supplied with matching mixing elements and various seals. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

LRE - Simple top-entry agitator The LRE is the most simple solution of an industrial agitator. It consists of a hollow shaft geared drive (worm geared, parallel shaft geared or helical bevel geared drive) and a rigid cast steel bearing housing. Due to this construction high torques are achieved. The agitator shaft is borne within the gear box and the bearing housing and is divided by a flanged coupling below the mounting flange. According to your tank size, the LRE series agitator is available in four different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm are realized. Sealing housings supplied with shaft seals in various materials are feasible, stuffing boxes or mechanical seals are an alternative. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The LRE is the most simple solution of an industrial agitator. It consists of a hollow shaft geared drive (worm geared, parallel shaft geared or helical bevel geared drive) and a rigid cast steel bearing housing. Due to this construction high torques are achieved. The agitator shaft is borne within the gear box and the bearing housing and is divided by a flanged coupling below the mounting flange. According to your tank size, the LRE series agitator is available in four different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm are realized. Sealing housings supplied with shaft seals in various materials are feasible, stuffing boxes or mechanical seals are an alternative. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

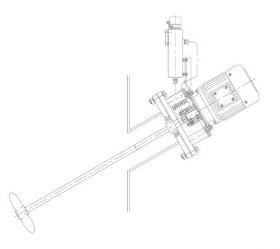

PDR - Side-entry agitator Side-entry agitator for mixing below liquid surface. The PDR is a simple side-entry-agitator for mixing below the liquid surface. The PDR is recommended for applications where low viscous liquids are mixed turbulently in high tanks and where a top-entry mixer would be too heavy due to its shaft length and –diameter. The sealing between the agitator and the vessel is done by means of a single-acting, internal mechanical seal which is lubricated by the mixing product or an additional fluid The agitator shaft is connected to the drive directly with a flange coupling inside the seal housing. By default, this agitator series is supplied with marine type propellers. Other mixing elements according to the mixing task upon request. Solutions correspond to those of the SPR, additionally mechanical seal in sealing housing. Other solutions for this series upon request.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

SPR - Standard-propeller-agitator The direct driven agitator SPR is Geppert Rührtechnik’s solution for all industrial mixing tasks that demand a turbulent mixing with high peripheral speeds. It is driven by a three-phase-motor with poles between 2 and 8 as well as drive ratings between 0.25 kW and 75.0 kW. The SPR could also be equipped with a frequency inverter upon request (up to 7.5 kW). The agitator shaft is directly connected at the shaft journal of the drive via sleeve or flange coupling. Solutions with quick-change or precisions-change coupling are also feasible for lower drive ratings of up to 3.0 kW. The standard agitator element is a propeller. Other mixing elements according to the mixing task upon request. The SPR can be mounted as a stationary unit or – at a weight of up to 25 kg – it can also be mounted directly onto the open tank via a vessel clamp Up to motor size 112, all SPR series agitators can also be provided with reinforced shaft. Type test certificate...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

LRK - Top-entry agitators for rigorous requirements The top-entry agitator LRK is used to meet rigorous requirements regarding both bearing and smooth-running. In addition to its rigid cast steel bearing housing, this agitator series features a coupling housing with an elastic coupling to connect the drive with a shaft journal. Thus, the LRK can be supplied as a fast running agitator with long shafts. The agitator shaft is borne within the bearing housing and is divided by a flanged coupling below the mounting flange. According to your tank size, the LRK series agitator is supplied in six different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm can be realized. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3). Bearing housings with shaft seals of different materials are feasible, alternatively with stuffing boxes or mechanical seals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRK - Geared agitator with helical bevel geared drive The GRK series geared agitator equipped with a helical bevel geared drive with reinforced bearing can be used for a wide range of applications due to its low installation height. This ow installation height can be achieved thanks to the horizontal position of the drive. The agitator shaft of the GRK series is directly mounted in the hollow shaft of the gear and, upon request, this agitator shaft can be divided by flanged coupling. After assembly of the mixer, the agitator shafts are balanced for concentric run. The GRK series features shaft lengths of up to 6,000 mm and drive ratings of up to 75.0 kW. It has a standard output speed of 1 to 250 rpm. According to the specific mixing task, the GRK series can be supplied with matching mixing elements and various seals. Upon request, we supply the GRK series with frequency controlled drives that have drive ratings of up to 7.5 kW. Type test certificate for explosive zone 0.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEPPERT RÜHRTECHNIK GMBH

Germany

Side-entry agitator for mixing below liquid surface. The PDR is a simple side-entry-agitator for mixing below the liquid surface. The PDR is recommended for applications where low viscous liquids are mixed turbulently in high tanks and where a top-entry mixer would be too heavy due to its shaft length and –diameter. The sealing between the agitator and the vessel is done by means of a single-acting, internal mechanical seal which is lubricated by the mixing product or an additional fluid The agitator shaft is connected to the drive directly with a flange coupling inside the seal housing. By default, this agitator series is supplied with marine type propellers. Other mixing elements according to the mixing task upon request. Solutions correspond to those of the SPR, additionally mechanical seal in sealing housing. Other solutions for this series upon request.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The direct driven agitator SPR is Geppert Ruhrtechnik’s solution for all industrial mixing tasks that demand a turbulent mixing with high peripheral speeds. It is driven by a three-phase-motor with poles between 2 and 8 as well as drive ratings between 0.25 kW and 75.0 kW. The SPR could also be equipped with a frequency inverter upon request (up to 7.5 kW). The agitator shaft is directly connected at the shaft journal of the drive via sleeve or flange coupling. Solutions with quick-change or precisions-change coupling are also feasible for lower drive ratings of up to 3.0 kW. The standard agitator element is a propeller. Other mixing elements according to the mixing task upon request. The SPR can be mounted as a stationary unit or – at a weight of up to 25 kg – it can also be mounted directly onto the open tank via a vessel clamp Up to motor size 112, all SPR series agitators can also be provided with reinforced shaft. Type test certificate numbers for zone 0 (category 1).

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The top-entry agitator LRK is used to meet rigorous requirements regarding both bearing and smooth-running. In addition to its rigid cast steel bearing housing, this agitator series features a coupling housing with an elastic coupling to connect the drive with a shaft journal. Thus, the LRK can be supplied as a fast running agitator with long shafts. The agitator shaft is borne within the bearing housing and is divided by a flanged coupling below the mounting flange. According to your tank size, the LRK series agitator is supplied in six different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm can be realized. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3). Bearing housings with shaft seals of different materials are feasible, alternatively with stuffing boxes or mechanical seals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRK series geared agitator equipped with a helical bevel geared drive with reinforced bearing can be used for a wide range of applications due to its low installation height. This ow installation height can be achieved thanks to the horizontal position of the drive. The agitator shaft of the GRK series is directly mounted in the hollow shaft of the gear and, upon request, this agitator shaft can be divided by flanged coupling. After assembly of the mixer, the agitator shafts are balanced for concentric run. The GRK series features shaft lengths of up to 6,000 mm and drive ratings of up to 75.0 kW. It has a standard output speed of 1 to 250 rpm. According to the specific mixing task, the GRK series can be supplied with matching mixing elements and various seals. Upon request, we supply the GRK series with frequency controlled drives that have drive ratings of up to 7.5 kW. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRW series is suited for a wide range of applications thanks to shaft lengths of up to 3,000 mm and drive ratings of up to 5.5 kW. It has a standard output speed of between 10 and 200 rpm. Low installation height thanks to horizontal position of the drive. The agitator shaft of the GRW series geared agitator is directly mounted in the hollow shaft of the worm geared drive. Additional flanged or clamp couplings can be implemented upon request. The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRW can be supplied with matching mixing elements and various seals. Upon request, we supply the GRW series with frequency controlled drives.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Combination one-part/multi-part with VKR buffers - Claw ring can be pushed back for checking the direction of rotation The TSCHAN ® TNB BHDV coupling is a torsionally flexible, puncture proof claw coupling. It compensates for angular, radial and axial shaft misalignments within defined limits. The coupling transmits torque through elastic buffers loaded in compression. These buffers come in perbunan (PB) or polyurethane (Vk), as a standard VkR. These elastic buffers dampen shocks and torsional vibrations and are resistant to oil. Buffers made of perbunan are electrically conductive. One of the coupling halves consists of a flange hub to which a claw ring is bolted. When the claw ring is removed, it is easily possible to check the rotational direction of the drive. The coupling is suitable for use in every direction of rotation and installation position. TSCHAN ®-TNB Type BHDV For short shaft distances, a combination of an one one-part design and a multi-part design coupling hub...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Combination one-part/multi-part with VKR buffers - Retractable claw ring The TSCHAN ® TNB BHD coupling is a torsionally flexible, puncture proof claw coupling. It compensates for angular, radial and axial shaft misalignments within defined limits. The coupling transmits torque through elastic buffers loaded in compression. These buffers come in perbunan (PB) or polyurethane (Vk), as a standard VkR. These elastic buffers dampen shocks and torsional vibrations and are resistant to oil. Buffers made of perbunan are electrically conductive. One of the coupling halves consists of a flange hub to which a claw ring is bolted. When the claw ring is removed, it is easily possible to check the rotational direction of the drive. The coupling is suitable for use in every direction of rotation and installation position. TSCHAN ®-TNB Type BHD Combination of a one-part design and a multi-part design coupling hub and VkR buffer. Easy replacement of the elastic buffer without axial movement of...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a hydraulic lange coupling (hereinafter called FKH) is the safe connection of two shafts. For example, between a drive shaft and a transmission shaft. The FKH produces a rigid and backlash-free connection between the shafts. This connection is mainly used to transmit torque, but can also absorb bending moments. The FKH is located in the power low. It is installed by sliding the FKH onto the shaft and the subsequent tightening of the hydraulic system. By using conical surfaces the inner diameter reduces and the radial pressure is built up. After clamping the FKH will be locked mechanically and the hydraulic pressure will be removed. Due to this simple approach, the FKH is suitable for repetitive clamping operations. Advantages of the FKH: • high transmittable torque and bending moments (high friction) • application-speciic design/customization • easy mounting and adjustment because of clearance it • relatively low pressure (closed system) • very rapid...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quoteResults for

Coupling flanges - Import exportNumber of results

41 ProductsCountries