- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- embossing machine tools

Results for

Embossing machine tools - Import export

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

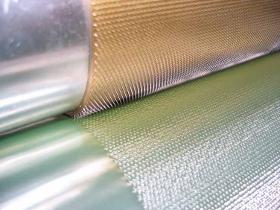

LT Ultra has also implemented the technology of metal-cutting microstructuring in roller lathes. We can offer the production of structures in a grid between 5 and 150 µm in optical quality for provided rollers.Offer up to a length of 2500 mm, a diameter of up to 800 mm and a maximum weight of 2500 kg.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

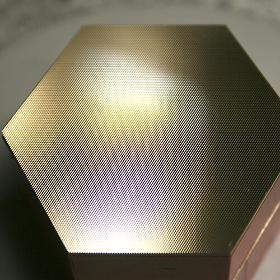

With the chip-removing microstructuring of metal surfaces, LT Ultra offers the right manufacturing technology for the production of embossing tools with optical surface qualities that allow economical replication in large numbers. Examples of microstructuring are the production of microfluidics or microlenses on our ultra-precise multi-axis machines. We can manufacture the structures directly in various materials such as brass, chemically deposited nickel or in selected hardened steels.For the replicating production of optical components, ultra-precise mold inserts made of steel are of particular interest due to their very long service life compared to other materials. In order to avoid the final polishing, which often leads to an undesirable change in shape or which is impossible due to a high structure density, LT Ultra offers ultrasound-assisted machining of steels with geometrically defined cutting edges made of monocrystalline diamond.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

for perforating thin aluminum sheets (eg heat protection sheets) and foils

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Domes produced with ECKOLD machines in automotive industry make sure that there is only a minimum offset between the securing screws and the surrounding metal. ECKOLD machines can produce two or even three domes in a single process. Our dome embossing machines are suitable for both single and double sheet steel or aluminium parts and come with a hydro-pneumatic or servo motor drive system. With our machines, domes can be embossed without preliminary holes (even when combined with final hole punching for a defined diameter). This offer includes: Dome embossing frame Embossings: 1 piece/stroke Embossing geometry: according to data set Drive: pneumohydraulic Mechanical interface: support stand Embossing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. We optionally offer hydraulic or servo motor drives as well as multiple embossings/stroke.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

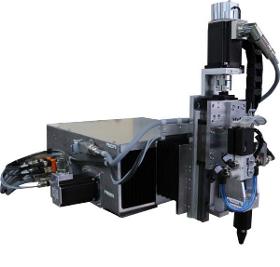

Embossing punching is an important technique in the automated production of car parts, guided by robots. A laser system with a sensor harness measures the car body and its machining plane so that the embossing depth can be determined with maximum accuracy. The car body part is then embossed accordingly and all necessary holes are punched. Embossing punching is used for the fixture of headlights, bonnets, sliding roofs, boot lids and locks as well as wings. Our embossing punching machines are suitable for single-layer steel and aluminium sheet metal. This offer includes: • Embossing punching frame (assembly elements or components can be perfectly aligned to a mating part of different dimensions) • Handling: robot-guided via defined interfaces (mechanical, electrical, pneumatic) • Servo motor-driven Tool inserts and measurement are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The 520 DOTStar is a compact workshop unit for permanent, flexible markings on almost every material. This BORRIES product offers the best technology in a low-wear and low maintenance design for an unrivalled competitive price. The large marking area offers the opportunity to mark single or multi lines texts, in free scalable size. Angle and circular arc markings are also possible as well as date, time and consecutive numeration. The marking data can be entered easily via the included BORRIES marking software VisuWin SE. A graphical user interface enables a quick installing and adapting of marking pictures (layouts). Available marking technologies: dot-peening, vibropeening and DataMatrix Coding (ECC200).

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in unit 322 is a highly robust device for 3-shift operation. All components of this coordinate unit have been developed for regular use and are continuously tested to ensure a constant quality. Together with a marking head and a controller this marker is integrated as a built-in unit in our special systems or by system producers for direct workpiece marking, e.g. in transfer lines, production machines or gauging and testing stations. The marking head is directly mounted underneath the coordinate unit. Marking areas 100 x 100 mm, 100 x 50 mm, 40 x 50 mm, 150 x 100 mm, 150 x 150 mm, 250 x 150 mm (X/Y) – other sizes possible.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 313 is best suited for many areas in industrial and handcraft applications where readable markings in dot marking, scribing or DataMatrix coding on materials like steel or aluminium are required. Due to its easy way of operating the device it is eminently suited for usage in workshops, in quality control and in stock management. Measuring rather small the model 313 still offers a large marking area of 120 x 20 mm. Even with larger font sizes markings of single or multi lines are possible. With the help of quick changing and optional workpiece support, it is possible to adapt to almost all workpiece geometries. With the compact marking controller EK2-Box there are numerous options of data input via PC, barcode scanner, SPS or the integrated membrane keyboard. Here, simple compilation and selection of the marking tasks is taking place as well. Font heights and font widths are freely scalable.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 320 is a compact marking unit for permanent and flexible markings on almost every material. This BORRIES product offers the best technology in a low-wear and low maintenance design for an unrivalled competitive price. The large marking area offers the opportunity to mark single or multi line texts, in free scalable size. Angle and circulate markings are also possible as well as date, time and consecutive numeration. The marking data can be entered easily via the included BORRIES marking software VisuWin SE. A graphical user interface enables a quick installing and adapting of marking pictures (layouts).

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 317 is a compact marker for permanent and flexible markings on almost all materials. Due to the ball bearing spindles and the carriage with circular ball track in both axes this model is very robust. The large marking area offers the opportunity to mark single or multi lines in free scalable dimensions. Angles and circular arcs, date, time and serial numbers are possible as well. Standard delivery is with LDM Macro software. Here, standard settings are printer or layout mode. Optionally VisuWin SE as well as VisuWin PRO PC software are available.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in marking unit 317 can be integrated in production lines as well as in stand-alone cells. The marking unit can also be mounted on other holding devices provided by the customer for example in production systems. The connection to a superordinate control (for example SPS) for data transfer or to control the marking process including emergency stop functions is possible. Standard delivery is with LDM Macro Software. Optionally VisuWin SE and VisuWin PRO PC software are available.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 312V is best suited for many areas in industrial and handcraft applications where readable markings in dot marking, scribing or DataMatrix coding on materials like steel or aluminium are required. Due to its easy way of operating the device it is eminently suited for usage in workshops, in quality control and in stock management. Measuring rather small the model 312V still offers a large marking area of 51 x 51 mm. Even with larger font sizes markings of single or multi lines are possible. With the help of quick changing and optional workpiece support it is possible to adapt to almost all workpiece geometry. With the compact controller EK2-Box there are numerous options of data input via PC, Barcode scanner, SPS or the integrated membrane keyboard. Simple compilation and selection of the marking tasks is taking place as well. Font heights and font widths are freely scalable.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

This easily transportable handheld unit for dot marking, stylus and DataMatrix coding is best suited for many areas in industrial and handcraft applications where readable markings on materials like steel and aluminium are required. Due to its good ergonomical features and its easy way of operating the device it is eminently suited for usage in workshops, in quality control and in stock management. The marking unit 312V is a portable marking device and is operated manually. Even with larger font sizes markings of single or multi lines are possible. This marking unit is available with table and column as a stationary workshop unit. The model 312V is setting new standards with a weight of only 5.5 kg. Measuring rather small it still offers a large marking area of 51 x 51 mm. With the help of quick changing optional workpiece support it is possible to adapt to almost all workpiece geometries.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in marking unit 312V can be integrated in production lines. It is suitable for plain text markings in stylus marking or DataMatrix coding in steel or aluminium. Scribe marking is also possible. Standard delivery is with LDM Macro software. Here, standard settings are printer or layout mode. As an option VisuWin SE as well as VisuWin PRO PC software are available. Diversity in marking technologies: scribe, Stylus or dot marking, DataMatrix coding (ECC 200).

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in marking unit 314 can be integrated in production lines as well as in stand-alone cells. The marking unit can also be mounted on other holding devices provided by the customer for example in production systems. The connection to a superordinate control (for example SPS) for data transfer or to control the marking process including emergency stop functions is possible. Standard delivery is with LDM Macro Software. Optionally VisuWin SE and VisuWin PRO PC software are available. Available marking technologies: scribe, stylus or dot marking, DataMatrix coding (ECC 200). Options • Pneumatic or electric adjustment unit (only in conjunction with EG2-Box) • Surface detection (only in conjunction with electric adjustment unit)

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

With its unique ergonomic features and ease of use, the device is ideal for mobile use. The scribe marking system type 317 is available with different handles for flexible adaptation and handling. Being a lightweight of 5.5 kg (without controller, pneumatic and chuck), the unit sets new standards. It offers a large marking area of 120 mm x 25 mm at its small dimensions. Via quick interchangeable, optional fixtures it is possible to adopt to virtually any vehicle geometries. The compact controller provides extensive opportunities for data input via PC, barcode scanner, PLC or the integrated keypad. By this keypad the easy creation and selection of the model-dependent imprinting orders is provided. Options • Vehicle-related fixtures with manual, pneumatic or magnetic clamp functionality

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in unit 313 can be integrated in production lines. It is suitable for plain text markings in stylus marking or DataMatrix coding in steel or aluminium. Scribe marking is also possible. Standard delivery is with LDM Macro software. Standard settings are printer or layout mode. As an option the VisuWin SE as well as VisuWin PRO PC software are available. Diversity in marking technologies: stylus, scribe and dot marking, DataMatrix coding (ECC 200).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BORRIES MARKIER-SYSTEME GMBH

Germany

The marking unit 315 is a very well protected and highly robust device designed for 3-shift operation. All components of this coordinate unit have been developed for regular use and are continuously tested to ensure a constant quality. The set of a marking head and a controller is integrated as a built-in unit by system producers for direct workpiece marking e.g. in transfer lines, production machines or gauging and testing stations. The pneumatic (PN) or stepping motor (SM) adjustment unit allows to forward the marking unit to the workpiece even at places which are difficult to access. Marking unit for marking processes: scribe, stylus, dot marking and DataMatrix coding (ECC200)

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 322 is a name plate marking unit and is used for very deep markings to mark individual components, prototypes and limited-lot productions. Stable, long life and low-maintenance machine design. Designed for continuous production. Available marking technologies: scribe, stylus, dot marking or DataMatrix marking.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS goes milling With its latest range of angular heads, EWS brings its trusted technology with new features to machining centres. The system range was presented to the public for the first time at EMO 2015. An elegant design houses high-performance technology, or to put it simply Precision meets Motion. Advantages: the smart solution for compensating for there not being a machining axis Machining hard-to-reach parts Centre boring stepless angle adjustment around the horizontal axis, with tangentially acting double cone clamp MR > 250 Nm Prerequisite: The prerequisite is a "stop block" on the machine. This prevents the entire unit from turning while simultaneously defining the position of the angel of rotation. Variations: basic duplex offset Request form: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

High-speed thread cutting with reversing kinematics The new EWS Tapmatic thread cutting head for driven tools enables thread cutting processes without having to reverse the direction of rotation thanks to its reversing kinematics. This saves time and energy and protects the motor – all this with a defined depth of thread. The units are available for M3-M12 threads.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Emulsion can do more than just cool... At least when using EWS Spinjet, the coolant is used to drive a turbine which allows the tool to rotate to up to 50,000 rpm, depending on the type. The turret's tool drive stops moving during this process! See the attached flyer for the technical requirements and details. Download Manual: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Keyway broaching on lathes is a common thing. What is new is to speed up this operation with low stress for the machine! Slot is driven by the tool turret of the machine, with the input rotary motion being converted to a translation with superimposed lift-off function. This makes programming extremely easy. The keyway broaching unit is positioned in the prepared bore – in such a way as to make the extended tappet oriented to the end position in the Z axis. The depth of the slot is produced by a constant X-feed moving between 0.04-0.08 mm/stroke. The speed of the spindle ranges between 400 R/min – 1,000 R/min, with one rotation corresponding to a complete stroke. This way, for instance, a feather key groove with a width of 6 mm and a depth of 5 mm is produced within 7.5 sec. (800 R/min and 0.05 mm feed/rotation). With this operation it is important that the chip can break at the end of the groove, that is that a cut-in or a bore exists.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Reaching concentricity 0 using a simple collet chuck and this within one minute: this is Zero-Zero. The specifically designed clamping nut with 6 symmetrically arranged screws at the circumference makes this step possible. The clamping nut is split, so that the inner ring can be minimally shifted. This simple technical finesse allows to eliminate tolerance additions. The machine operator only has to replace the previous clamping nut, which step opens up a new concentricity dimension – and this for a price starting at € 90.00. Zero-Zero is available for DIN 6499 collet chuck holders from ER 16-ER40.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The new EWS tcJet range Optimal chip transport thanks to EWS tcJet EWS tcJet transports the coolant through the inset directly to the cutter and guarantees optimal chip transport... At the same time, the cutting edges have a significantly longer service life. EWS's interior cooling version is available for normal and high-pressure applications for various tool holder fixtures and cutting insert manufacturers.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Compact and stable – this is EWS' new swivel head. The swivelling module, which is equipped with a Cylkro drive system, is 17 mm smaller than standard heads which, above all, offers greater flexibility in swivel ranges between 0° and 45° in the field of cutting tools. The swivel unit covers an angle of +/- 92°. During the swivelling process, the supply of coolant is directly carried along. A distance of at least 48 mm from the contact surface to the swivel axis can be proposed. Even a high-pressure interior cooling system of up to 70 bar can be built into the module without the exterior dimensions having to be modified. Rotational speed limit is 6,000 1/min, maximum transmittable torque is 16 Nm, and max. cutting tool diameter is restricted to 10 mm. The swivel head is mainly suitable for drilling or for simple machining tasks. EWS' TWK range is available. for greater demands with regard to torque and performance.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS quality now available for Swiss-type lathes. This new development in driven tools is EWS's response to many customers' requests. The tool systems may appear straightforward at first sight, but their simplicity belies their performance. The design concentrates on the mounting and the spindle concentricity. The requirement profile was developed jointly with an American medical technology company which uses very small drill bits and requires extreme concentricity properties. The spindle bearing technology used with labyrinth seals sets new standards in this field, and is associated with a long service life. Provision has already been made for service. The service centres in Germany, China, Korea and the USA have already been trained in the system and are ready to respond without delay. Third-party brands can also be serviced there at any time. Download catalogue: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS takes measures against vibrations in deep drilling procedures Deep drilling procedures with drilling rods with a long overhang are one of the most demanding tasks in cutting technologies. What influences vibration, what amplitudes does it create, what is the effect of superimposed vibration and when are uncontrollable resonances encountered? All these are questions that are difficult to answer using theory alone. These findings formed the basis for the new development of EWS Rigid. The objective was to create a drilling holder with a passive damping system to counteract the vibrations that are created. This involves using variable vibration dampers with linear degrees of freedom in a floating mounting inside the cutter carrier. The damper position is set using a radially mounted setscrew, which allows optimum vibration conditions to be created. The improvement in surface qualities of bores is significant, as is the increase in the service life of cutter tools.

Request for a quoteResults for

Embossing machine tools - Import exportNumber of results

39 ProductsCountries

Company type