- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial ovens

Results for

Industrial ovens - Import export

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Customers worldwide use Datapaq® temperature profiling and monitoring systems with their powder coating equipment in automotive and industrial powder coating to optimize product quality, reduce waste and prove compliance with ISO9000. When standard and specialty systems will not meet your exact application requirements, Datapaq will build a custom system using Insight™ thermal profiling software, an extensive range of custom barriers and thermocouples, as well as the Datapaq DP5 and Datapaq TP3 data loggers. In addition, Datapaq offers a complete thermal profiling system for real-time data analysis -TM21 Radio Telemetry System. Oven Tracker Insight Software Datapaq powerful Insight analysis software has been designed specifically to convert raw temperature data into meaningful information that can be used to understand, control and optimize your cure process. Complex calculations are simplified, allowing quick and comprehensive analysis.

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Flowmeters especially for gases The VA 45 variable area flowmeters were designed to measure gases. They can be used, for example, in industrial ovens, forges and furnaces, and protective gas and heating systems. The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 600 6 zone reflow soldering oven is the space saving and inexpensive solution for the numerous standard SMT soldering tasks. Taking up a small amount of floor space and having low energy consumption, the machine has all the advantages of a larger reflow soldering oven such as perfect thermal properties as well as comprehensive equipment including useful features.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

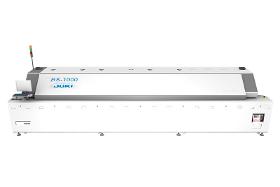

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven With its 10 heating zones and 2 cooling zones JUKI’s RS 1000 helps create even ambitious profiles and improve towards a high throughput of printed circuit boards respectively. Top flexibility is therefore guaranteed for future applications as well. In spite of a higher count of heating zones, the energy consumption is low.

Request for a quoteResults for

Industrial ovens - Import exportNumber of results

7 ProductsCountries

Company type