- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser station

Results for

Laser station - Import export

NANOSYSTEC GMBH

Germany

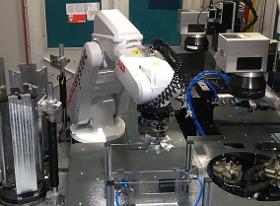

The laser processing station VersaCut precisely ablates and cuts a large variety of materials, such as metals (stainless steel, nonferrous metals), ceramics like Si or AlN, and all kind of plastics. Depending on the indented use, the station uses different laser sources with the corresponding focusing optics. The modular VersaCut finds it application in research and production.A solid-state laser delivering short pulses in the nanosecond regime is ideal for cutting stainless steel, Kovar, brass and similar metals. The high peak power with a small focus on the target generates the necessary power density for clean and sharp cuts. There is however an impact on the surrounding area as some local heating occurs. The high peak power allows also for cutting and ablating plastics, even if the laser wavelength does not match the linear absorption of the plastic.

Request for a quote

NANOSYSTEC GMBH

Germany

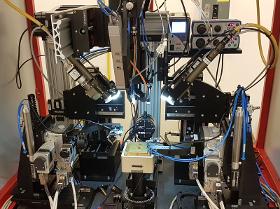

NanoHybrid provides a large degree of versatility. The active alignment, test and assembly station combines various assembly methods including gluing, laser welding or selective laser soldering. In addition, the station offers opto-electronic testing capability. Therefore, NanoHybrid is ideally suited for the development and small serial production in manufacturing companies or in research institutes. In such a product development area, an active alignment station needs to cope with opto-electronic and other precision devices with varying sizes and characteristics.

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The latest generation of color laser printers have four toning stations (CMYK). Paper passes all four stations in one cycle which enables higher print speeds. This design requires precise positioning of the belt with respect to the paper during the toning cycle. This need defines the properties of a seamless belt for a perfect printout: Perfect, defect-free surface Tight tolerances of diameter, length, width and surface roughness Precisely defined electrical conductivity over the entire belt surface KB RollerTech`s capabilities: Diameters: up to 1,000 mm Width: up to 600 mm Thickness: 50 - 100 µm (±10%) Electrical properties: 1E5 - 1E16 Ohm cm Roughness: < 1,0 Ra Primary and Transfer Charge Rollers Charge rollers are critical for long lasting, high quality printouts in laser printers and copiers. KB Roller Tech’s special compounds enable charge rollers to maintain continuously stable electrical properties. Primary charge rollers are mostly soft coated rollers with sensitive surf

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Laser station - Import exportNumber of results

3 ProductsCountries

Company type