- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine maintenance

Results for

Machine maintenance - Import export

RHEIN-CHEMOTECHNIK GMBH

Germany

Maintenance oil for machines, mixers, moulds and mixings trucks, significant reduction of cleaning time, extends lifecycle of treated machines. Very good sticking, strong releasing effect, facilitates fast and easy cleaning, contains additional corrosion-inhibitors.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Some 3,000 different types of brushes in our off-the-shelf store are just waiting to go into action. And if the right one is not amongst them, we will design a customised solution to help out in an emergency. You have a problem, we solve it – that’s the deal. Whether in the course of regular machine maintenance or an unexpected repair job: We can supply a broad range of replacement parts within 24 hours, starting with single parts. Because we have decades of experience in stocking carbon brushes. For special individual productions, we coordinate with you using photographs or construction drawings, then make samples of your requirements, produce the required tooling, and move quickly into production and assembly. Carbon brushes and brush holders from a single provider. And if you like it easy, then our Carbon brush configurator can ‘advise’ you. Using the online tool you can easily make enquiries about or order typical small and industrial carbon brushes directly.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

PULLALIGN is an easy to handle laser alignment system to simply but efficiently align pulleys. Pulley alignment reduces wear of the pulleys, increases machine efficiency, extends the planned maintenance intervals, und finally leads to cost and energy savings.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Why vibration analysis? Information available regarding lifetime of the gearbox Detection of damages on gearset or bearings, impacts, imbalance Lifetime extension of the gearbox and prevention of sudden gearbox failures Cost savings through prevention of unscheduled machine stops Timely maintenance measures before gearbox failure: change of bearings, gearset and other effected parts, replacement gearbox More Information about SmartCheck

Request for a quote

FILLPACK GMBH & CO. KG

Germany

2 x 2 dosing pumps with motorised individual adjustment from 0 – 500 ml nearly maintenance-free machine with automatic central lubrication system Fully-automatic cleaning of filling machine (CIP/SIP) Quick and simplified format change (15 min.) Two filling machines enabling alternate operation/cleaning Heatable hopper (35°C – 95°C) Diversion and feeding of filled jars to the cooling zone Film applicator station Sealing station Multi-transport plate for all current jar diameters

Request for a quote

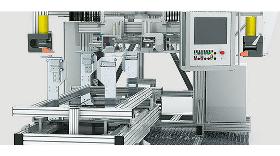

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

HERBERT WALDMANN GMBH & CO. KG

Germany

MKEL meets the particularly high requirements of the foodstuff industry. The LED integrated machine luminaire is used in packaging machines where it prevents accumulation of dirt and is distinguished by its resistance to agents for sterilising packages or the machine. • Maintenance-free LED technology • Robust aluminium housing with plastic screen • Self-adhesive seal • High degree of protection • Chemically resistant to many media such as cleaning and sterilising agents • Ideal for high thermal stress • Nearly flush-mounted installation • Prevents accumulation of dirt • Direct connection to machine voltage • M12 plug connector

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

From the project planning stage through to the end of their operating life we offer a range of concepts for economical and fault-free operation of your machines Target-oriented maintenance intervals to match the respective operating conditions Online and offline status monitoring Trend measurements relating to wear behaviour of the mechanical and electrical components Stocking spare parts for shorter downtimes Training for maintenance staff 24 hour service Company-oriented maintenance contracts Modernisation of the machine, controllers and protection equipment Environmentally compatible recyclingTesting of electrical machines and systems, type tests, system tests, heat run tests according to DIN standards Dynamic balancing or rotors Cleaning and oven drying of large machine parts such as stators or rotors VPI impregnation with rotating hardening process in drying oven VPI impregnation of transformers and large coils VPI or resin-rich coil production Manufacture of tooth-wound coils

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series F1 - F4 The HEINKEL inverting filter centrifuge of the Series F requires minimum installation space and is characterized by an integrated clean room design. It is suited for use with diffcult to filter products and characterized by hermetically closed design and the fully automated, continuous operation. Special properties for the customer’s benefit: Advanced development of the proven inverting filter centrifuge Series HF Larger basket volume as well as higher centrifugal forces in comparison with Series HF Easy installation, especially in clean rooms because of outer smooth surfaces and machine contours Inerting system and all junction boxes accommodated in the machine housing Easy access to machine housing via maintenance doors at three sides

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Screen Printer PMAXII Large scale printers such as the PMAXII from JUKI made by GKG are designed for three shift operation and a long service life with low maintenance requirements. The machine table and squeegee carrier are cast, not welded. Therefore guaranteeing high torsion resistance and ensuring the print accuracy will remain unchanged for years. JUKI’s PMAXII handles large circuit boards of sizes up to 1,220 × 800 mm and has notably specialised on LED applications.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Surging demand by the pelletizing industry has caused a shortage of available saw dust and shavings. Numerous industries, like wood–based panelboard producers and the power plants are forced to find alternative sources. Substitution of suitable replacements has become urgent to ensure a fibre supply and to prevent shortages. Wood chips are often the only available source. Because of increasing numbers of produc-tion lines for pellets and particleboard a shortage of small fibre, has resulted. The flake produced from wet wood chips by the optimally PHMC hammer mill, can be used as an additional source or a 100% substitute of saw dust. Advantages Processing of wet chips (moisture u > 100%) Flake preparation of chips to a coarse saw dust type material Ensure the fibre supply in existing processing lines High machine availability at lowest maintenance an labour costs Independence from saw dust supply Future-proof for the usage of different material types by simple adjustment of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Surging demand by the pelletizing industry has caused a shortage of available saw dust and shavings. Numerous industries, like wood–based panelboard producers and the power plants are forced to find alternative sources. Substitution of suitable replacements has become urgent to ensure a fibre supply and to prevent shortages. Wood chips are often the only available source. Because of increasing numbers of produc-tion lines for pellets and particleboard a shortage of small fibre, has resulted. The flake produced from wet wood chips by the optimally PHMC hammer mill, can be used as an additional source or a 100% substitute of saw dust. Advantages Processing of wet chips (moisture u > 100%) Flake preparation of chips to a coarse saw dust type material Ensure the fibre supply in existing processing lines High machine availability at lowest maintenance an labour costs Independence from saw dust supply Future-proof for the usage of different material types by simple adjustment of...

Request for a quote

SANHA GMBH & CO. KG

Germany

Practical system push fittings with safe and innovative lock function from copper alloys for use in a system with SANHA MultiFit®-Flex and MultiFit®-PEX multi layer plastic tubes for hygienic drinking water and reliable heating installations. Due to their sophisticated construction, SANHA system push fittings offer an especially safe and durable connection and are just as tight as press fittings. The push connection is easy to make and has the distinct advantage that no tools are required. In this way, using 3fit®-Push fittings incurs no cost for buying, repairing or maintenance of press machines. 3fit®-Push system fittings are ideally suited in narrow spaces where it might be difficult to press fittings with jaws or slings such as during the renovation of buildings.

Request for a quote

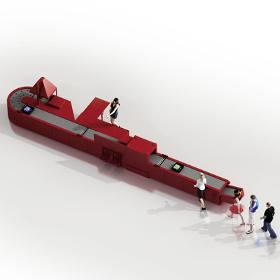

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Hand Baggage Control Unit conforms to the latest standard of technology and requires minimal staff involvement for handling. The defined field of use is automated hand baggage transportation into containers with automatic container return. This keeps the manual handling of the containers to a minimum. The security personnel can focus entirely on checking passengers and baggage. UltraSimple Adjustments Ultrasimple adjustment to required installation conditions with modular system Universal Compatibility Can be combined with all conventional XRay machines. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

OPTIMA NONWOVENS GMBH

Germany

High packaging quality is always the crucial factor. The OPTIMA HS/OS3 bag packer and packaging provides the right packaging to best showcase logos and printing at the point of sales. The adjustable high compression further enhances quality and brings with it a number of advantages in logistics. Optima Nonwovens packaging machines are flexible: The machines can be adjusted quickly and easily for a large range of formats, format sets and modules. Fully automatic high-speed stacker for baby diapers Quick and easy change-over Quality gate Modular machine structure Designed for easy maintenance

EHRT MASCHINENBAU GMBH

Germany

EHRT's standard bending machine EB 40 is distinguished by their extreme robustness and simple handling. The machine is modulary and flexibly structured, so that each machine can be individually adapted to the customers’ needs. EHRT bending machines can perform a multitude of bending modes. Offset bending, flat bending, edge bending, torsion bending, closed shapes and U-bends are some examples. The hydraulic cylinder of the bending machine is fitted with a force of 344 kN. The machine offers an outstanding bending accuracy of 0.2°. A special plug-in system makes tool changing very user-friendly on the EHRT machines. This guarantees very fast setup times and yet robust and precise bending tools. Beckhoff's PLC machine control enables machine maintenance and software updates via remote access.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 322 is a name plate marking unit and is used for very deep markings to mark individual components, prototypes and limited-lot productions. Stable, long life and low-maintenance machine design. Designed for continuous production. Available marking technologies: scribe, stylus, dot marking or DataMatrix marking.

Request for a quote

HAVER NIAGARA GMBH

Germany

The NIAGARA® scalper is the best choice for crushing plants or the classification of coarse and difficult-to-screen materials at high throughput rates and fluctuating material feed rates. The unique NIAGARA® drive system generates a constant circular vibration motion at a fixed amplitude. The amplitude remains unchanged over time, no matter what the material load is. The application area of the NIAGARA® Scalper covers a variety of industries and materials with a length of up to 2000 mm and a cut size of 2 - 450 mm. Advantages reduced loads and energy demands for the subsequent crushing plant increased crusher capacity maximising the quality of the crushed product quick and easy re-balancing is always possible built with long-life bearings maintenance-friendly, modular machine design dynamically balanced construction modernisation of existing plants, performance improvement You’ll find detailed information in our product brochures and specification sheets.

Request for a quoteResults for

Machine maintenance - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Bending machine tools (2)

- Concrete products and conglomerates (1)

- Conveyor systems (1)

- Copper and copper alloys (1)

- ELECTRICAL SYSTEMS (1)

- Embossing machine tools (1)

- Induction heating systems (1)

- Industrial screen printing (1)

- Lighting, street, industrial and commercial (1)

- Monitoring and control equipment (1)

- Paper and cardboard manufacturing - machinery and equipment (1)

- Rolling mills - machinery and installations (1)