- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- testing equipment

Results for

Testing equipment - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel custom screws.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for printer accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Uses for precision high-tech product accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Machine parts processing.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test gas set for testing gas detection and gas measuring devices GPL and GPD. According to the DVGW rules, a weekly check with 1 vol% CH4 is necessary. With screw-on extraction adapter and display of the flow. Delivered with conditioning filter in a carrying case (not including GasPen).

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for revising gas detection devices. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. Rather than a pressure gauge, the PS 403-U has a vacuum manometer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

For checking the gas detection and gas measuring devices. All gases can be connected in 12 liter aluminum pressurized gas cans.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. Rather than a pressure gauge, the PS 403-US has a vacuum manometer. In the PS 403-US model, the control buttons are replaced by toggle switches. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station to review the gas detection devices. The control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 is possible. All gases can be connected to 1 liter aluminum compressed gas cans. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

You can find the gas concentration needed for each device in the user's manual. There are additional costs for shipping by air freight. We recommend using the test gas set or a sampling valve.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

Portable high resolution CR scanner for all NDT radiography applications - weld inspection, profile images and aerospace Unique 30 μm basic spatial resolution – BAM-certified Scans flexible imaging plates up to 35 cm in width Widest range of applications thanks to TreFoc Technology Intuitive handling & easy transition from film Portable and compact (17.5 kg) What does TreFoc Technology mean and how does it work? TreFoc Technology is the name for the our new laser focussing technology, uniquely in systems from DÜRR NDT. With TreFoc the laser beam is adjusted perfectly to give optimal image results and the highest signal-to-noise ratio in any application. Inside the laser tube, an iris diaphragm adjusts the laser beam diameter. Since the perfect laser beam diameter can be selected for each object and image type, optimum results for any particular application can be easily achieved. Regardless of the application – high-resolution image or low-exposure c

Request for a quote

MERECS ENGINEERING GMBH

Germany

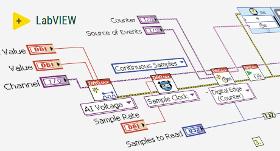

We develop electrical test systems based on NI-PXI or NI-cRIO that can take on real-time capable measurement and control tasks. In addition, we can provide the FPGAs that can be used on the NI systems and the real-time operating system with software individually tailored to customer requirements.

Request for a quote

MERECS ENGINEERING GMBH

Germany

We design and manufacture individual test systems for the pressure testing of valves and pumps. Merecs Engineering has a competent network of partners for this purpose. Within this framework, we carry out the risk assessment, design, manufacturing, installation and commissioning. In addition, we connect the systems to the individual IT infrastructures (databases, ERP systems, MS PowerBI) of our customers.

Request for a quote

MERECS ENGINEERING GMBH

Germany

We develop fully automatic test systems for inclination sensors and inertial sensors (MEMS, tilt sensors) according to customer requirements. With these systems, combined temperature and motion simulation is possible. We set quality standards with rate tables from Acutronic, for example. With the help of multi-axis rate tables, we can precisely position DUTs in end-of-line (EoL) test operations or for development purposes and calibrate and test them under temperatures of e.g. -40°C and up to 120°C. Merecs Engineering can also connect the test system to our customer's IT infrastructure, set up databases and automatic data analysis using Mircosoft PowerBI, so that important key figures such as First Pass Yield (FPY), process capability, system availability, statistics and trends are continuously updated and displayed on online dashboards. For example, more than 100 DUTs are possible per test run.

Request for a quote

MERECS ENGINEERING GMBH

Germany

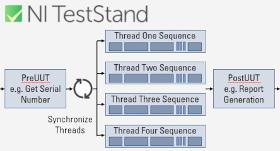

As an NI Alliance Partner, we use NI TestStand and NI LabVIEW for test automation. Python, C/C++ Embedded and Microsoft PowerBI can be used in addition. NI-TestStand is the industry standard test management software and is used by the developers and architects at Merecs Engineering with a lot of experience. We offer for example the following services: - Requirements analysis based on the DUT properties to be tested - Development of test cases in cooperation - Sequence development in TestStand - Intuitive custom user interfaces - Parallel testing of many DUTs & Badge Testing - Reporting (SQL databases etc.) - Trainings & Workshops Our developers hold the CLA (Certified TestStand Architect) and CLD (Certified TestStand Developer) certificates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

The system is a self-sufficient unit and is made of a solid welded frame, contains media preparation, a hydraulic unit, and electrical engineering. The pressure test bench has a secure test chamber for burst pressure and hydrostatic pressure tests and, optionally, a climatic chamber for pressure tests with environmental simulation. Depending on the option selected, pressure change tests up to 2,000 bar and 10 Hz can be generated. With the test circuit for hydrostatic and burst pressure tests, pressure ramps up to 3,000 bar can be generated. It is operated on a support arm PC. For pressure tests according to EG79 / EU406 – Section 4.2 Pressure booster for additional supply Displacement volume max. 15cm³ Frequency up to 10Hz Pressure Load Changes as sine & trapezoidal curve (depending on the expansion volume) Impulse intensifier for small volumes up to 2,000bar Safety test chamber with automatic door Media treatment with dirt and clean tank

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

Autofrettage is a method for increasing fatigue strength of components for use at high and pulsating pressures. In short, Autofrettage compresses a container’s inner surface, making better use of the material’s structural properties. The process can reduce fatigue concerns in pulsating applications and lets engineers reduce tubing thickness in high-pressure applications without sacrificing strength, life, or safety. The autofrettage method is based on the reciprocal relationship of the plasticized inner zone and the elastically deformed outer zone. The components are placed under so much pressure that their interiors become plastically deformed. After relaxing, pressure stresses are created in these areas, which prevent the outer areas from reforming to their original shape. Instead, it remains stretched. This prevents crack formation in the later application, increases the service life of

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

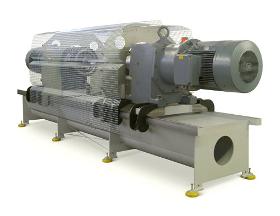

The Poppe + Potthoff impulse test stands test the operating or fatigue strength of various metal and plastic components. The endurance test in our high-pressure test systems simulates the life-cycle under varying loads. The failure tests thus show the potential weaknesses of the components with respect to design and material. The pressure is optionally modulated as a sine wave, trapezoid curve or needle pulse. Our test stands are characterized by a special ergonomics and are designed by Poppe + Potthoff machine design. Due to our flexible modular design, our machines are very variable, so that the pressure and volume range is designed according to the customer’s requirements. Of course, our systems are UL or CE compliant as required. In addition, we offer you service and support directly on-site.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

In order to prove the quality of the fluid-carrying parts, all hoses, pipes, pressure vessels and other components are put under pressure until they burst. The process is precisely measured and documented in order to optimally design the components for specific applications.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

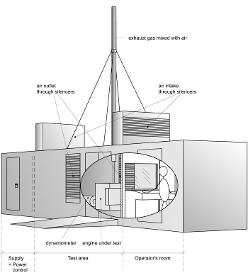

Two kinds of fuel are changed in the engine repeatedly without mixing. Thus also small differences in the specific consumption, the emissions and further values measured at the engine which are influenced by the fuel will be clearly visible. The engine is charged by a coupled braking dynamometer (engine test bed). At the test bed, different load conditions may be adjusted. The reproducibility of the experiments is secured by the speed stabilisation and the automatic gravimetric determination of the specific fuel consumption of the MP Computer. Example of application: Testing the efficiency of fuel additives or of other kinds of fuel pretreatment.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

For Example: Container 40 ft for outdoor installation for performance testing at combustion engines with all kinds of dynamometers. Depending on the kind of the installed dynamometer, external supply beyond electricity (e.g. for cooling water) will be required. Thanks to our mobile engine supports, there is no need of an overhead gantry crane or any other lifting device.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

- self-supporting bed, - no transfer of torque to the ground - rapid fixation of modules and additional equipment in any axial position without drilling Picture: The modules executing torque on each other consist of electric motors with a high torque transmission. They are secured by strong clamping elements on the test bed. Their axial position is adjustable. The removable protection grid protects only against accidental contact to rotating parts under laboratory conditions. Solid axially movable protection covers are avaiable if parts might detach and fly away.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

Transportable engine supports minimize the times of standstill of the engine test bed, as the engines can be built up and tested separately. The mounted engines can be coupled to the engine test bed quickly and without any effort. RWB mobile operation trolleys and Universal Engine Supports may be used with MP dynamometers and with other suitable dynamometers (by Weinlich or other manufacturers). Their modular design allows interchangeability and reusability. RWB are mobile thanks to swivel rollers. They have a load capacity of max. 800 kg. A RWB mobile operation trolley has a low base frame from which single supports lead up to the fixing points of the engine. By this design all parts of the engine can be reached as well as possible. Thanks to its solid and proven construction the mobile operation trolley is nevertheless able to match up to the stress during power tests. Universal Engine Supports have a higher load capacity (1000 kg and 2000 kg) than RWB. ...

Request for a quote

DATAPHYSICS INSTRUMENTS GMBH

Germany

The optical contact angle meters of the OCA series are high-precision measuring systems for the characterisation of interfaces and surfaces. They combine high-resolution optics, pinpoint liquid dosing and precise sample positioning to create powerful, reliable measuring systems. The entry-level model OCA 15EC enables basic methods of professional contact angle measurement and drop shape analysis. Thanks to the modular construction, even this entry-level model can be combined with many accessories, such as the TBU 100EC tilting unit. Possible Measurements: - static contact angle - dynamic contact angle - interfacial/surface tension - surface energy - viscoelastic modulus - work of adhesion

Request for a quote

DATAPHYSICS INSTRUMENTS GMBH

Germany

The tensiometers of the DCAT series are measuring instruments for force-based investigation of surface and interface properties. Because of the compact and modular product design of the DCAT series, a bespoke combination of device and accessories can be found for any use case. The DCAT 9 is the powerful entry-level model of the product series. It allows the measurement of surface and interfacial tensions as well as the determination of the density of solids and liquids. Possible measurements: - surface and interfacial tension - density of solids and liquids

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

laserXtens Array HP features a measuring head incorporating seven fixed high-resolution cameras. The overlapping fields of view of the seven cameras are combined into a single large image, giving a very large measuring range.Advantages of laserXtens Array - laserXtens Array HP possesses an extremely large measuring range, combined with a resolution of 0.10 μm. - laserXtens Array HP has no moving parts and is completely maintenance-free. - laserXtens Array HP satisfies the requirements of Class 0.5 of ISO 9513 (Class B2 of ASTM E83). - Used for strain-rate-controlled tests to ISO 6892-1 Method A1 (closed loop) for gage lengths from 30mm. Different gage lengths can be set in fractions of a second. laserXtens Array HP can also measure transverse strain with no need for additional markings; biaxial measurement is additionally possible. Determination of strain distribution and strain at break as per Annex H of ISO 6892-1

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The zwickiLine testing machine is equally ideal for research and development as it is for routine quality assurance testing. Development and manufacture of the zwickiLine, including all mechanical, electronic, and software components—together with the comprehensive range of accessories — takes place at ZwickRoell's production facility in Germany, so all components work together seamlessly. Your benefits: - load range from 500 N up to 5 kN and with test-area heights from 565 mm to 1365 mm - Low weight, a small footprint and space-saving design - Suitable for tensile, compression, flexure and bending tests on different materials and components - Wide range of specimen grips and testing tools

Request for a quoteResults for

Testing equipment - Import exportNumber of results

102 ProductsCountries

Company type

Category

- Testing equipment (64)

- Measurement and control instruments (7)

- Electrical & Electronic Components (6)

- Engine testing and regulating equipment - electronic (4)

- Non-destructive tests (3)

- Measurement - Equipment & Instruments (2)

- Machinery and equipment, used and reconditioned (2)

- Radiology equipment, industrial (2)

- Ballistic equipment and testing (1)

- Optical measuring equipment (1)

- Testing of products and materials (1)

- Bearings, roller (1)

- Boilerwork (1)

- Foundries - machinery and installations (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Precision measuring instruments (1)

- Ultrasonic measuring equipment (1)