- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tig welding

Results for

Tig welding - Import export

WIGTEC FISCHEREDER KG

Germany

Tungsten inert gas (TIG) welding offers many advantages over other fusion welding methods, such as the complete absence of spatter and low welding-fume emissions. Since TIG welding uses a non-consumable electrode, the process is ideal for welding so-called root passes or in forced positions due to the decoupling of current and welding consumables.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

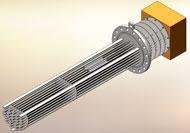

Electrical flange type immersion heaters The range of immersion heaters type FHK offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

EEx’e‘ certified immersion heater EEx e T1 – T6 ATEX The “FHK-Exe” type electric immersion heaters are EExe certified. These heaters are custom built to meet client specifications and suitable for use in zone 1 & 2 hazardous areas. The range of immersion heaters type FHK-Exe offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust Ex’e’ terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

New employees are first introduced to TIG welding in a basic training lasting several months. Only then are the first products manufactured for customers, whereby the following topics are handled in a multi-year development process, which includes the welding test for the tube welder CrNi relatively early: Material requisition Additional materials Gas protection Interpass temperature and welding temperature Maximum material temperature during welding Cleaning the weld seam Welding distortion Mechanical seam load

Request for a quote

ORBITEC GMBH

Germany

Lightweight, compact inverter power source for TIG manual or orbital welding (automatic detection) in conjunction with all Orbitec controllers. Technical Data: Output: DC Mains voltage: AC 1 x 230V Mains frequency: 50 / 60Hz Power rating: 4.4kVA Generator output: 7.5kVA Current range: 5A – 200A Welding current: - 25% TIG / MMA: 200A - 60% TIG / MMA: 150A - 100% TIG / MMA: 120A Weight: 8.9kg Dimensions (L x W x H): 475 x 180 x 295mm Package includes: - Inverter - Power cable Optional: Cool 50 water cooling unit Inverter Tetrix 200 (auto-range) as an additional model (control range 5 - 200A | 110 / 230V | item number 1.2.0120): Same characteristics as Tetrix 200 inverter but an input voltage of 115VAC or 230VAC can be used. No switching required as the unit recognises the input voltage and adjusts automatically. Note: Maximum output of 150A when used with 115VAC.

Request for a quote

ORBITEC GMBH

Germany

Mobile inverter power source for TIG manual or orbital welding with built-in cooling system and gas sensor. Can be used with all Orbitec controllers, particular in high-demand applications such as tube-to-tube-sheet. Technical Data: Output: DC Mains voltage: AC 3 x 400V Mains frequency: 50 / 60Hz Power rating: 15 kVA Generator output: 20.3 kVA Current range: 5A – 350A Welding current: - 60% TIG / MMA: 350A - 100% TIG / MMA: 300A Cooling efficiency: 1500W Water column: 35m / 5l / min. Tank capacity: 12l Weight: 131kg Dimensions (L x W x H): 1100 x 455 x 1000 mm Package includes: - Inverter - Power cable - 10l coolant

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The benefits of using aluminium in machine and plant construction are abundant: although aluminium is considered to be a light metal with a density of 2.6 to 2.8 g per cm³, which offers potential weight savings of up to 66% compared to steel and stainless steel, it still has exceptional strength considering these properties. However, the design and concept of steel constructions can often not be transferred one-to-one, due to the higher malleability and lower residual stress of aluminium components. An additional benefit is the aluminium's inherent resistance to corrosion: When exposed to oxygen, the light metal forms an oxide coating, which is immediately regenerated upon permeation. Standard processing methods, such as MIG, TIG and CMT welding can easily be used on aluminium without hesitation – particularly on substrates that are also made of aluminium. In some instances, they can be carried out more easily, more quickly and using simpler equipment, which results in further...

Request for a quote

EWM AG

Germany

EWM welding consumables for MIG/MAG welding Welders can choose between different welding rods with different diameters and materials to work with: — unalloyed steels — low-alloy steels — high alloy steels — Nickel-based materials — aluminium alloys — Copper-based materials — Hardfacing

Request for a quote

EWM AG

Germany

TIG welding torches, gas- or water-cooled from 150 A (gas-cooled) up to 400 A (water-cooled). — TIG welding torch with a highly flexible hose package — Ergonomic GRIP handle for a secure hold and ergonomic use — Excellent HF reliability — Ready to weld with tungsten electrode, gas nozzle and back cap

Request for a quote

EWM AG

Germany

— GMAW standard and pulsed welding — Synergic characteristics for steel, CrNi and aluminium — MMA welding and TIG liftarc welding — Perfect for welding self-shielding flux cored wires — Infinitely adjustable arc dynamics (choke effect) — Synergic or manual welding operation — Interval welding — Adjustable gas pre- and post-flow time — Portable, compact — Saves power through highly efficient performance — Robust casing suitable for construction site use — 4-roll drive for 0.8 mm and 1.0 mm steel wires — Easy, tool-free change of welding polarity — IP23 spray water protected — Wire spool diameter up to 200 mm/D200 — 3.5 m mains supply lead with 16 A shock-proof plug — Mains connection 230 V/16 A — High mains voltage tolerance +15%/-40% and therefore fully generator-compatible — Free WPQR package for certification up to and including EXC2 in accordance with EN 1090 and for welding of unalloyed steels up to and including S355

Request for a quote

EWM AG

Germany

— Gas-cooled DC TIG inverter welding machine — TIG welding with high frequency starting — TIG lift arc welding without HF — MMA welding — MMA pulse welding and pulsed TIG welding up to 2 kHz — Reduced secondary current accessible using torch trigger — Adjustable up-slope/down-slope — Adjustable gas pre-flows/post-flows — Adjustable hot start current and hot start time — Adjustable Arcforce — Antistick function — Energy-saving thanks to high efficiency and standby function — Portable, including shoulder strap — 3.5 m mains supply lead with 16 A shock-proof plug — Mains connection 230 V/16 A — High mains voltage tolerance +15%/-40% and therefore fully generator-compatible — Overvoltage protection: No damage to machine caused if inadvertently connected to 400-V mains voltage

Request for a quote

EWM AG

Germany

TIG inverter welding machine with high frequency start. Thanks to the modular structure, the machine can be retrofitted with an additional water block without using any tool. With the two available control variants (Smart 2.0 or Comfort 2.0), a variety of functions are available: — TIG Liftarc welding without HF — MMA pulsing — TIG pulsing (sec/kHz) up to maximum 15 kHz — TIG AC welding — TIG AC pulsing (sec/special) — Non-latched/latched operation — Adjustable up-slope and down-slope time — Adjustable gas pre- and post-flow time — MMA welding — Adjustable hot start current and hot start time — Adjustable Arcforce — Antistick function Available as DC and AC/DC variant with optional torch connection for standard start/stop welding torch or up/down torch.

Request for a quote

EWM AG

Germany

— Inverter welding machine, DC — Very light-weight, only 4,7 kg – housing made of aluminium and impact-resistant plastic — Portable, shoulder strap — MMA and TIG lift arc welding — Cellulose electrodes: 100% safe for vertical-down welding — Welding of stick electrodes up to 4 mm — Pulsed MMA welding: — Especially suitable for root welding — Outstanding gap bridging with no sagging of the root side — Fine-flaked weld surface with a TIG look for final passes — Less finishing work thanks to less spatter — Ideal for difficult electrodes — Less distortion thanks to controlled heat input — Pulsed TIG welding with up to 2 kHz — Connection capability for remote control — IP23 spray water protected — Arcforce, hot start, antistick — Energy efficient due to standby mode — 3.5 m mains lead with 16 A earthed plug — Overvoltage protection: No damage to machine caused if inadvertently connected to 400-V mains voltage

Request for a quote

EWM AG

Germany

— Modular plasma/TIG welding machine with Comfort 2.0 P control — Plasma and TIG welding — Plasma and pulsed TIG welding — Plasma and pulsed TIG welding up to the kHz range allow a high welding speed with minimal heat input using a constricted arc — Plasma and TIG welding current adjustable in 0.1 A increments — Pilot arc current adjustable in 0.1 A increments between 2–15 A — The pilot arc current can be adjusted at four operating points during the welding process (beforehand, during, and following welding, as well as during pauses in welding) — Non-latched/latched operation — Spot welding/tack function (spotArc/spotmatic) — Spotmatic – reduce the time required for tacking by up to 50% (TIG only) — Adjustable up-slope and down-slope time — 3.5 m mains supply lead with 16 A shock-proof plug

Request for a quote

EWM AG

Germany

Fully automatic welding helmet with extra bright view in light state (shade level 2.5) — Exact compliance of the set shade level thanks to digital auto darkening filter — Higher safety and relief to the eyes thanks to shade level 2.5 in light state — Optional: Comfort lining to add to the headband — With true colour filter for a true colour view — Never before seen realistic colour perception thanks to new sensor technology — Adjustable arc recognition angle by means of sensor slider — Infinitely adjustable shade level control — Operating unit outside helmet — Grinding mode — Synergic or manual welding mode

Request for a quote

EWM AG

Germany

Compact inverter welding machine with integrated wire feed mechanism. Available with 3 different control variants: LP, HP, Expert 2.0. Can be retrofitted with optional modular water block Cool 50 U40 or tool box for storing welding accessories, e.g. welding torch. — Excellent Multimatrix welding characteristics — Equipped at no extra charge with Synergic characteristics for GMAW welding of steel/CrNi/aluminium — Equipped at no extra charge with EWM Synergic characteristics for forceArc, forceArc puls, rootArc, rootArc puls and superPuls — Suitable for MMA welding, TIG welding and gouging at no extra charge — 16 individually configurable programs for each welding task (JOB) — Large power reserves thanks to high duty cycle with all components heating up less as a result, guaranteeing a longer service life for machines when in use — Adjustable start and end crater functions — Synergic or manual welding mode

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTC DAIHEN EUROPE GMBH

Germany

With the properties of the new DT300P digital power source, TIG welding can be significantly simplified: There are numerous options in a compact 30 kg unit. With a multitude of pulse options, the device can be ideally set for different tasks: A controlled heat supply ensures optically clean and even seam structures during low-pulse welding (up to 20Hz) - especially with different material thicknesses. The high arc stability in high-pulse welding (from 20 to 500 Hz), on the other hand, is demonstrated in the lower current range, especially in thin sheet metal applications: welding can be carried out without any problems from a material thickness of 0.3 mm. The robust 80 kHz IGBT inverter stands for reliability and extreme arc stability - even with low currents. The digital control panel, which is designed for rough industrial use, offers many advantages for the user.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

Welbee W400: Precise adjustment and arc stability – even in the lower welding area* Precise adjustment of energy input due to AC pulse welding process * High-speed AC pulse welding due to improved features for the respective material * Welding shape looks like TIG welding process due to AC wave pulse technology * High melting rate, weld penetration control * Extended application scope due to 400 A at 40% rated duty cycle

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

With repetition accuracy of up to ± 0.07 mm, the new high accuracy robot can succeed in even the most demanding of tasks. The deviation from circular diameters of ≤ 10 mm is max. 0.09 mm - half as much as with commercial robots. • Position Accuracy: Highest precision regardless of robot position. • Precision machining: The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The main technical specifications at a glance: Number of axes: 6 Working Range (P-Point): R 1664 mm Max. payload capacity: 20 kg Positional repeatability: +/- 0,08mm Drive System: AC Servo Motor Drive Power: 7900 W Weight: 355 kg

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

InFocus: Precise, reliable und reproducible InFocus is a high-performing TIG technology. Its precision and reliability make the InFocus welding process particularly suitable for automated applications in combination with linear axles, robots and other guiding systems. Nearly all steels, non-ferrous metals or galvanized sheets can be welded in one layer with or without filler material; e.g. CrNi-steels with a material thickness of up to 10 mm. For welding root layers of thicker sheets, the InFocus welding process offers an alternative. By using the TIG keyhole welding process, the web can be made bigger. This reduces the seam cross section and thus the number of the required layers during the subsequent submerged-arc welding. It is also not necessary to gouge the root when using the InFocus welding process for the root layer.

Request for a quoteResults for

Tig welding - Import exportNumber of results

22 ProductsCountries

Company type