- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- panels- wood

Results for

Panels- wood - Import export

CONTAIN HAUS

Germany

Dimensions Width 2.40m, Length 6.00m, Height 2.61m Square meters 14.40m² NEW! MADE IN GERMANY Description Facilities Cafe Container Floortoceiling windows with wood paneling, 1x room, 1x entrance door completely glazed Isolation 80 mm ceiling, 80 mm wall All electronic installations are included (fuse box, 230V sockets, ceiling lights, switches, cable ducts, cables). On request we offer transport with unloading. The surcharge is 300 € Individual room design is possible. In addition, you can order the following Roller shutters (incl. Einabu) 390 € Flow heater shower (incl. installation & sealing) 400 € Water boiler sink (incl. installation & sealing) 300 € Heating wall (incl. installation, cable & cable duct with socket) 280 € Frost Guard €75 Desired color of paintwork (incl. processing) 750 € The price does not include VAT

Request for a quote

HEAVYDRIVE GMBH

Germany

Vacuum suction systems with special plates for rough surfaces such as stone slabs, plastic panels, wooden panels, wood based boards and much more up to 6000 kg.

Request for a quote

IRUS-SYSTEM

Germany

The Irus sign holders are available in 4 different designs. There are various types of panel, e.g. glass, wood, plastic, PVC, metal etc. and varying panel thicknesses with visible or concealed screw connections. We have the correct connector for every type of panel, size or thickness. There is no need to drill the panels when using Irus sign holders, simply clamp the panel with the connectors and mount the sign using the plug on the respective wall. The sign is quick and easy to mount in the correct position. The major advantage of the Irus sign holder is that the panel does not require drilling. The principle is simple „ the bigger the panel the more sign holders are required. Different sizes of sign can be mounted and the positioning of the holders is freely selectable. Whether at the top, at the bottom, at the right or left, whether 1, 2 or several sign holders, you are free to make your own choice. Panels with a thickness of 3-5 or 5-8 mm can be used.

Request for a quote

JA-DE GMBH & CO. KG

Germany

As a supplier to the furniture industry, we manufacture bent or roundcut fronts of solid wood in a variety of wood types (beech, oak, maple, red alder, etc.). For example, our products include solid wood doors, front panels for drawers, round frame doors, and doors for display cabinets. With respect to 3D features, our use of 5axis CNC technology allows us to realise every element with the utmost precision radii, contours, borings, mitre joints, etc. Do you have special requirements for the cut and surface finish? No problem!

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for universally usable refurbishment wax for mending surface damages and small defects in varnished, oiled or glazed wood surfaces indoors, such as doors and furniture, wall panels and wood parts.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for mending damages, scratches and small defects on any wooden surface indoors such as doors and furniture, wall panels and wooden parts. Retouching Pen distinguishes itself by virtue of its high quality. Ideal for any wooden surface. Easy use, instant result. The beveled tip guarantees easy application, even in corners and angles

Request for a quote

ABS SAFETY GMBH

Germany

Once attached to a beam using the 2 long screws provided - with the 14 smaller ones screwed straight into the wooden panelling - this stainless steel anchorage point (Ø 16 mm) and its base plate (200 x 200 mm) reliably protect roof workers & Co. from falling. This device was awarded national technical approval by the German Institute for Construction Technology (DIBt). National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 abZ: Wood min. 24mm EN 795: Wood min. 24mm Incl. installation set Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

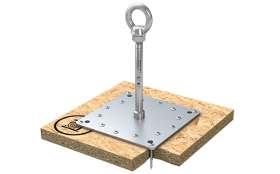

This anchorage point (Ø 16 mm) has been awarded national technical approval ("abZ"). It is equipped with a base plate (200 x 200 mm) and is screwed straight onto the wooden panelling. Our standard package includes 16 high-quality screws which - like the whole system - are manufactured from weather-resistant stainless steel material. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 National technical approval (“abZ”): OSB ≥ 22 mm, or similar, e.g. tongue and groove boards or glulam planks EN 795: Wood ≥ 24 mm, OSB ≥ 18 mm Optionally, the device can be installed using an additional 12 mm OSB board: Wood ≥ 20 mm, OSB ≥ 12 mm Incl. installation set Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

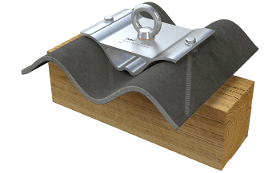

This stainless steel anchorage point is equipped with a wavy aluminium base plate which fits snugly to the waves of a fibre cement roof (wave distance 177 mm). The anchor device is simply screwed onto a wooden beam using the screws provided. EN 795:2012, A + CEN/TS 16415:2013 Special wave design, e.g. for Eternit and similar roof systems Developed for load-bearing wooden structures Simply screw it onto one single wooden beam Min. beam dimensions: 100 x 120 mm

Request for a quote

ABS SAFETY GMBH

Germany

The thread of this no-nonsense stainless steel anchorage point (Ø 16 mm) is screwed straight through the wooden panelling into the beam. Simply drill a hole through the panelling (at least 18 mm) and into a load-bearing wooden beam (min. 80 mm x 120 mm). EN 795:2012, A + CEN/TS 16415:2013 Designed for load-bearing wooden structures Minimum beam dimensions: 80 mm x 120 mm Depth of wooden panelling: ≥ 18mm

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Be it boxes, bags, drums or wood panels. Be it cabinets, enclosures or crates. Be it in the food processing industry, in chemical companies or a logistics company: Vacuum tube lifters from AERO-LIFT facilitate work in almost all areas of application and can improve the workflow in almost every sector. This saves time and ensures that your employees have a pleasant workplace. And it motivates and makes processes more efficient. The major advantages of AERO-LIFT vacuum tube lifters are obvious – Try and discover them! Function and features The AERO-LIFT tube lifters are based on one single concept: Suction-Lifting-Lowering-Release. Numerous additional functions ensure an easy and ergonomic working. Physical stress due to lifting, stooping and moving the load up to 300 kg can be avoided to a large extent. In addition to a horizontal transport, the load can be turned: either manually by sheer muscular...

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel roof safety hook - specially designed for tiled roofs - is equipped with a cranked shaft for bridging the roof lathing. Is it simply installed by screwing the 2 stainless steel screws supplied through the counter lathing and into the woodem beam. We also supply an optional installation set for flexible attachment to a specially-prepared wooden panel (instead of a beam). This roof hook can be implemented as a natural conducting component in a lightning protection system (100 kA) in accordance with EN 62305-3 Roof safety hook in accordance with EN 517:2006, type B Anchorage point + ladder hook Designed for load-bearing wooden structures Simply screw it onto a wooden beam (also suitable for over-rafter insulation) Min. beam dimensions: 60 mm x 120 mm Installation materials included

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

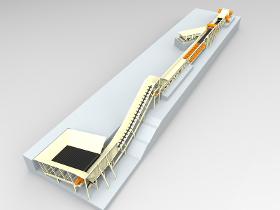

The quality and consistency of akes have a signicant inuence on board properties. Knife-ring akers are exible and can be individually adjusted to meet aking requirements. The professional preparation of chips leads to the right akes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent ake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Combining plant eciency and reduced environmental impact Energy systems from Büttner provide stable process heat for your wood based panel production Process

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

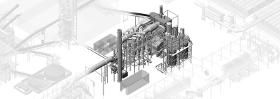

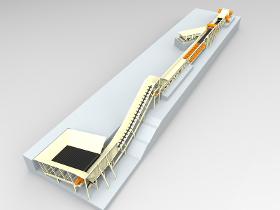

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-efficient drum chippers, the production of high-quality chips is guaranteed. Features, Function Simple feeding of wood directly from the truck Robust underground bins or vibrating...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Finding out the unrealized potential through the use of weight per unit area gauges One of the most vital factors in the production of wood panels is the constant spreading of material. If tolerances are exceeded, higher material and energy consumption are the consequences. MSX, which constantly moves back and forth across the mat before it enters the hot press, maintains tolerances within the optimum range. The result is homogeneous forming in lengthwise and crosswise directions. The enormous technical developments of “Weight per Unit Area Gauges” of the past years are physically not visible. What are the previous limitations of weight per unit area gauges? The x-ray tube needed a cooling device. This resulted in a reduced lifetime. Electronic Wood Systems developed a detector with extremely high sensitivity – probably unmatched in the world. Due to this new detector the net power could be reduced to a small portion of the permitted power.

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

At the beginning of the process for manufacturing wood-based panels is the technology for the professional size reduction of the different wood types. The quality of the chips, strands, flakes, or fibers determines the quality of the panel. Anything neglected at this stage of the process cannot be made up later on. For this reason Siempelkamp offers the complete range of machines for the production of high-quality chips. Technological competence and intensive development work, based on market and customer requirements, result in optimal customer-specific solutions. The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-efficient drum chippers, the production of high-quality chips is guaranteed. Features, Function Simple feeding of wood directly from the truck Robust underground bins or vibrating...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHAKE GMBH

Germany

or safe crossing of ditches and canals, galvanized steel frame, with access ramp for wheelchairs, prams, etc., wood cover and skirting of all-wood panel with several coatings. Slip-resistant cover all round, weather-resistant impregnation ensures long life, the side rails are equipped with red-white-red reflecting stripes. Both railings can be removed for space-saving transport and storage. This ditch bridge complies with the workplace and ZTV-SA ordinance, Load: 150 kg / m2

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp Bond Analyzer BLOW-SCAN is a detection systems which automatically detect blows and unbonded areas during the production of wood panels. It utilizes ultrasound and therefore is suitable for harsh production environment. Self-Calibration takes place in each panel gap. This compensates inuences raised from waste deposits and temperature variations. The models CONTI-SOUND and BLOW-SCAN are preferably installed in particleboard, MDF and OSB production lines. Changes of the panel properties are shown so the measurement can be used as an early warning System Features and Function Board thickness < 60 mm Density > 550 kg/m3 Detectable blow size > 28 mm Online calibration Automatic adjustment of sensor sensitivity Automatic recognition and compensation of dust load on sensors Automatic compensation of temperature drift Real-time data analysis Remote service

Request for a quote

STI GROUP / STI - GUSTAV STABERNACK GMBH

Germany

Flexible modules from black lacquer wooden panels showcase individual product categories from Philips Lighting in hardware stores. If the product line is changed, only the panels need to be changed. To preserve the high-end look, the euro pallet under the POS display is overlaid with black lacquer sheet. The unit is suitable for transport and is delivered fully assembled and wired to retail stores.

Request for a quoteResults for

Panels- wood - Import exportNumber of results

21 ProductsCountries